Content Menu

● What Is SMT Splice Tape and Why Is It Essential for Electronics Manufacturing?

>> Understanding SMT Splice Tape

>>> Types of SMT Splice Tape

>> The Importance of SMT Splice Tape in Production

>> Selecting the Right SMT Splice Tape Supplier

>> Applications of SMT Splice Tape

>> Innovations in SMT Splice Tape Technology

>> The Role of Quality Control in SMT Splice Tape Production

>> Visual Guide to SMT Splice Tape

>>> SMT Splice Tape

>>> Application of SMT Splice Tape

>> Common Challenges in Using SMT Splice Tape

>> Best Practices for Using SMT Splice Tape

>> Future Trends in SMT Splicing Technology

>> Frequently Asked Questions (FAQs)

>> Conclusion

What Is SMT Splice Tape and Why Is It Essential for Electronics Manufacturing?

Understanding SMT Splice Tape

SMT splice tape is a specialized adhesive tape used to join two ends of carrier tapes that hold surface mount devices (SMDs). This splicing process allows manufacturers to continue feeding components into machines without interruption, thereby minimizing downtime and maximizing efficiency.

Types of SMT Splice Tape

1. Single Splice Tape: Used for basic splicing needs, providing a straightforward solution for connecting two tapes.

2. Double Splice Tape: Offers enhanced strength and reliability, making it suitable for high-speed production lines.

3. ESD-Safe Splice Tape: Designed to prevent electrostatic discharge, crucial for sensitive electronic components.

The Importance of SMT Splice Tape in Production

Using SMT splice tape effectively can lead to significant improvements in production efficiency:

- Reduced Downtime: By enabling quick transitions between tapes, manufacturers can keep their production lines running smoothly.

- Cost-Effectiveness: Minimizing machine downtime translates to lower operational costs.

- Improved Quality Control: High-quality splice tapes ensure that components remain securely attached during the manufacturing process.

Selecting the Right SMT Splice Tape Supplier

When choosing an SMT splice tape supplier, several factors should be considered:

1. Quality Assurance: Ensure that the supplier adheres to strict quality control measures. A reputable supplier will have certifications such as ISO 9001 or IPC standards, which demonstrate their commitment to quality.

2. Product Range: A diverse range of products allows manufacturers to find the right solutions for their specific needs. Suppliers should offer various types of splice tapes suitable for different applications and environments.

3. Technical Support: Suppliers should offer expert advice and support to help manufacturers optimize their processes. This includes guidance on the proper application of splice tape and troubleshooting any issues that may arise.

Applications of SMT Splice Tape

SMT splice tape is used across various sectors within electronics manufacturing:

- Consumer Electronics: In devices like smartphones and tablets where space is at a premium, SMT splice tape ensures that production runs smoothly without interruptions.

- Automotive Industry: For assembling electronic components in vehicles, where reliability is paramount. The automotive sector often requires high-performance materials that can withstand extreme conditions.

- Industrial Equipment: In machinery that requires precise electronic controls, SMT splice tape helps maintain the integrity of connections throughout the manufacturing process.

Innovations in SMT Splice Tape Technology

Recent advancements in adhesive technology have led to the development of more efficient and reliable SMT splice tapes. These innovations include:

- Enhanced Adhesive Formulations: Providing stronger bonds and better performance under various environmental conditions. For example, some modern splice tapes are designed to withstand high temperatures or humidity levels without losing adhesion.

- Customizable Solutions: Suppliers are now offering tailored splice tapes designed for specific applications or machinery. This customization can involve adjusting the width, thickness, or adhesive properties based on customer requirements.

The Role of Quality Control in SMT Splice Tape Production

Quality control is paramount in the production of SMT splice tape. Manufacturers must implement rigorous testing protocols to ensure that their products meet industry standards. This includes:

- Adhesion Testing: Ensuring that the tape adheres properly under various conditions.

- Temperature Resistance Testing: Evaluating how well the tape performs at different temperatures.

- Durability Testing: Assessing how well the tape holds up over time, especially in high-speed applications.

Visual Guide to SMT Splice Tape

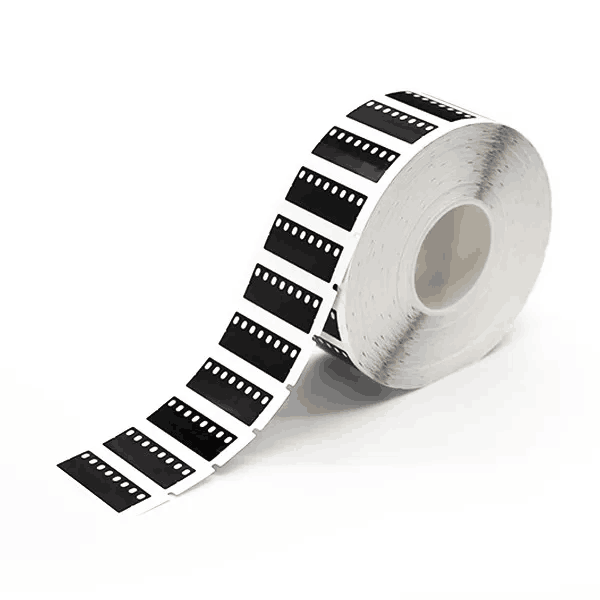

SMT Splice Tape

*An example of SMT splice tape used in electronics manufacturing.*

SMT Splice Tape

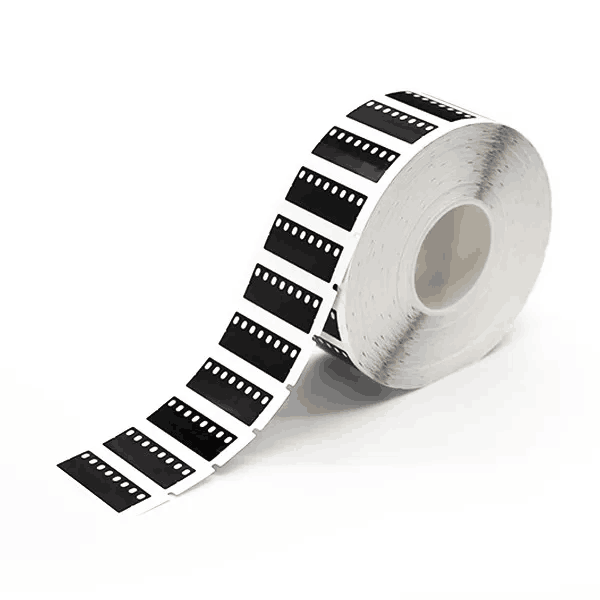

Application of SMT Splice Tape

*SMT splice tape in action on a production line.*

Common Challenges in Using SMT Splice Tape

Despite its advantages, there are challenges associated with using SMT splice tape:

1. Improper Application: If not applied correctly, splice tape can fail, leading to component misalignment or damage.

2. Environmental Factors: Humidity and temperature can affect the performance of adhesive tapes. It's essential to choose a product suitable for the specific conditions of your manufacturing environment.

3. Compatibility Issues: Not all splice tapes are compatible with every type of carrier tape or SMD. Manufacturers must ensure they select appropriate products based on their specific needs.

Best Practices for Using SMT Splice Tape

To maximize the effectiveness of SMT splice tape in your production process, consider these best practices:

1. Training Staff: Ensure that all personnel involved in the splicing process understand how to apply the tape correctly.

2. Regular Maintenance: Keep machines well-maintained to prevent issues that could lead to improper splicing.

3. Quality Checks: Implement routine checks to ensure that spliced connections remain secure throughout production.

Future Trends in SMT Splicing Technology

As technology continues to evolve, several trends are emerging in the field of SMT splicing:

- Automation Integration: More manufacturers are integrating automated systems that utilize advanced sensors and robotics for splicing operations, improving speed and accuracy.

- Sustainability Efforts: There is a growing emphasis on sustainable materials in adhesive products, with suppliers exploring eco-friendly alternatives for adhesive formulations.

- Smart Manufacturing Solutions: The rise of Industry 4.0 is leading to smarter manufacturing processes where data analytics can optimize splicing operations based on real-time performance metrics.

Frequently Asked Questions (FAQs)

1. What is the primary function of SMT splice tape?

- The primary function is to join two ends of carrier tapes without interrupting the production process.

2. How do I choose the right type of SMT splice tape?

- Consider factors such as the type of components being used, production speed, and environmental conditions.

3. Can SMT splice tape be used with all types of SMDs?

- Yes, but it's essential to ensure compatibility with specific machines and components.

4. What should I look for in an SMT splice tape supplier?

- Look for quality assurance, product range, and technical support.

5. How does using high-quality SMT splice tape affect production?

- It reduces downtime, enhances product quality, and ultimately lowers operational costs.

6. What are common mistakes when applying SMT splice tape?

- Common mistakes include not aligning the tapes properly or applying too much pressure during application.

7. Are there any specific storage requirements for SMT splice tape?

- Yes, it should be stored in a cool, dry place away from direct sunlight to maintain its adhesive properties.

8. How do environmental factors impact the performance of SMT splice tape?

- High humidity or extreme temperatures can weaken adhesion and lead to failure during production.

9. What advancements are being made in adhesive technology for SMT applications?

- Innovations include stronger formulations and environmentally friendly adhesives designed for specific industrial needs.

10. Can I customize my order for SMT splice tape?

- Many suppliers offer customization options based on width, thickness, and adhesive type tailored to your specific requirements.

Conclusion

In conclusion, SMT splice tape is an indispensable tool in modern electronics manufacturing. By understanding its importance and selecting a reliable supplier, manufacturers can significantly improve their operational efficiency. As technology continues to advance, staying informed about the latest developments in SMT splicing solutions will be crucial for maintaining competitiveness in the industry.