Content Menu

● Understanding the Wholesale PCB SMT Production Machine Line

>> Key Components of a Wholesale PCB SMT Production Machine Line

● Strategies to Optimize Your Production Process with a Wholesale PCB SMT Production Machine Line

>> 1. Streamline Process Flow

>> 2. Prepare Components and Feeders in Advance

>> 3. Utilize Advanced Robotics and Automation

>> 4. Implement Real-Time Monitoring and Smart Manufacturing Integration

>> 5. Optimize Solder Paste Application and Reflow Profiles

>> 6. Invest in Operator Training and Maintenance

>> 7. Embrace Continuous Improvement and Feedback Loops

● Benefits of Using a Wholesale PCB SMT Production Machine Line

>> Enhanced Efficiency and Throughput

>> Improved Quality Control

>> Scalability and Flexibility

>> Cost-Effectiveness

>> Environmental and Safety Benefits

● Innovations Driving the Future of Wholesale PCB SMT Production Machine Lines

● Conclusion

● FAQ

>> 1. What is a wholesale PCB SMT production machine line?

>> 2. How does automation improve PCB production efficiency?

>> 3. Can a wholesale PCB SMT production line handle different PCB designs?

>> 4. What role does real-time monitoring play in SMT production?

>> 5. How important is operator training for SMT production lines?

Optimizing the production process in electronics manufacturing is essential to meet increasing market demands, improve product quality, and reduce costs. A wholesale PCB SMT production machine line offers a comprehensive solution to achieve these goals by automating and streamlining the assembly of printed circuit boards (PCBs) using Surface Mount Technology (SMT). This article explores how to optimize your production process effectively with a wholesale PCB SMT production machine line, highlighting key components, strategies, benefits, and future trends.

Understanding the Wholesale PCB SMT Production Machine Line

A wholesale PCB SMT production machine line is a fully or semi-automated assembly line designed to produce PCBs efficiently and with high precision. It integrates several specialized machines and systems that work together to automate the entire SMT process, from solder paste application to final inspection.

Key Components of a Wholesale PCB SMT Production Machine Line

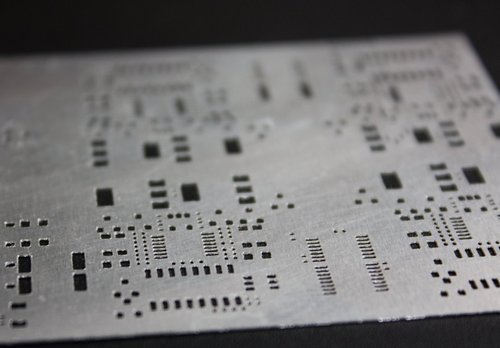

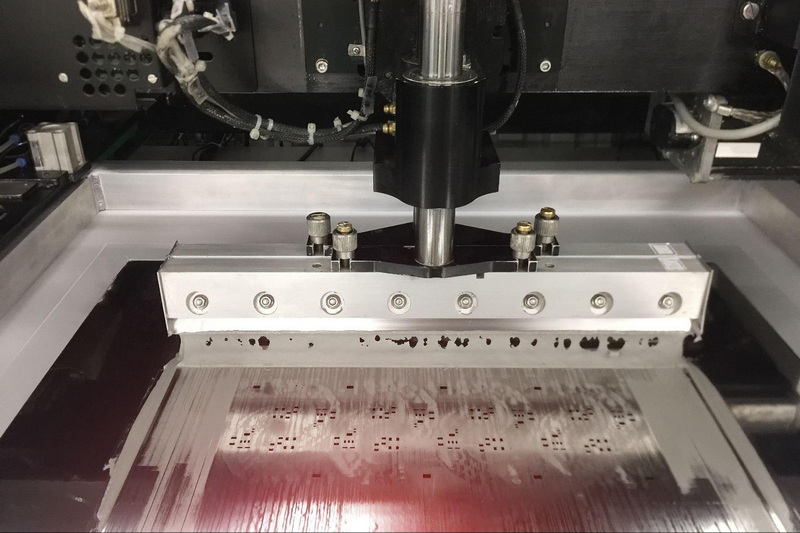

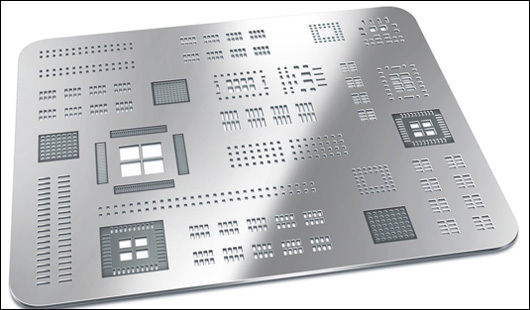

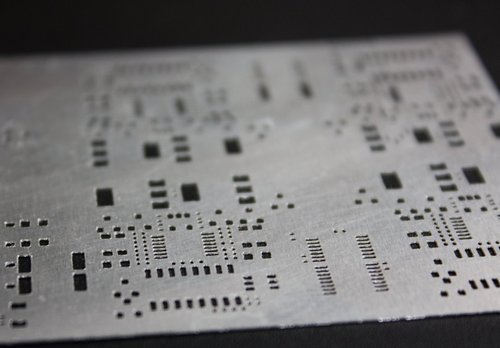

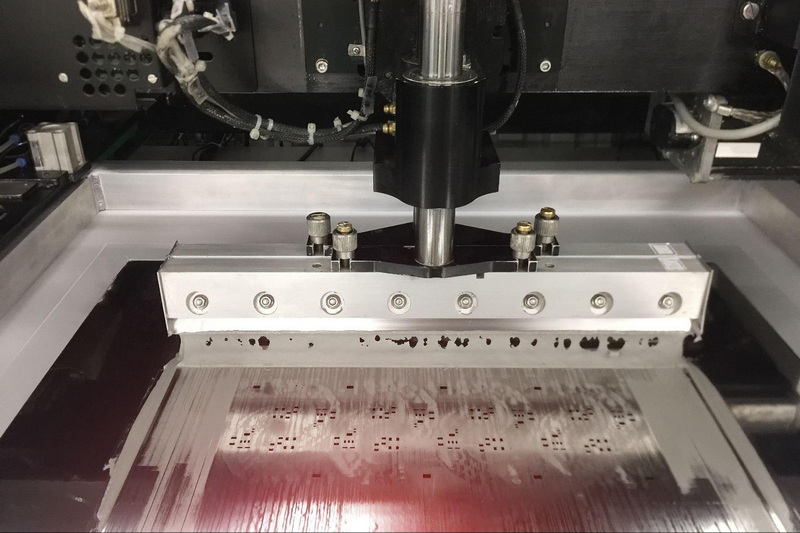

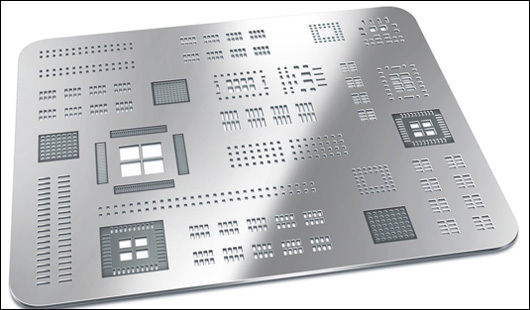

- Solder Paste Printer: Applies solder paste accurately onto PCB pads, which is crucial for ensuring strong solder joints during the reflow process.

- Pick and Place Machines: Automatically place electronic components onto the PCB with high speed and precision.

- Reflow Oven: Heats the PCB to melt the solder paste, forming permanent electrical and mechanical connections.

- Inspection Systems: Use vision-based technology to detect defects and ensure quality control throughout the assembly process.

- Conveyors and Automation Systems: Transport PCBs between machines, minimizing manual handling and increasing throughput.

These components work synergistically to create a seamless production flow, reducing manual labor and human error while increasing production speed and consistency.

Strategies to Optimize Your Production Process with a Wholesale PCB SMT Production Machine Line

To fully leverage the advantages of a wholesale PCB SMT production machine line, manufacturers must adopt specific strategies that enhance efficiency, quality, and flexibility.

1. Streamline Process Flow

Optimizing the process flow is fundamental. Arrange the production line to minimize unnecessary movement of PCBs and components. This involves careful layout planning to ensure that each machine is positioned to reduce transport time and handling. For example, placing the solder paste printer immediately before the pick and place machine reduces the risk of solder paste drying out or smearing.

Standardize operating procedures to reduce operator errors and improve consistency. Document each step clearly and train staff to follow these procedures meticulously. This consistency helps in maintaining quality and reduces variability in production output.

2. Prepare Components and Feeders in Advance

Efficient preparation of components and feeders is critical for maintaining continuous production. Organize feeders by component type and placement priority to reduce machine downtime during feeder changes. Implement just-in-time feeder replenishment to avoid interruptions. This means monitoring feeder status in real-time and scheduling component loading before the machine runs out.

Additionally, maintaining an organized inventory system that tracks component consumption and availability helps prevent production delays caused by missing parts.

3. Utilize Advanced Robotics and Automation

Incorporate robotic automation for precise component handling and placement. Multi-head gantry-type chip mounters can place multiple components simultaneously, significantly increasing throughput. Advanced motion control algorithms optimize machine movements, reducing cycle times and enhancing accuracy.

Robotic systems can also handle a wide range of component sizes and shapes, from tiny resistors to large integrated circuits, improving the line's flexibility. This automation reduces the risk of damage to delicate components and ensures consistent placement accuracy.

4. Implement Real-Time Monitoring and Smart Manufacturing Integration

Integrate smart manufacturing systems that provide real-time data analytics and adaptive control. This enables predictive maintenance, early detection of defects, and process optimization. IoT-enabled SMT lines allow remote monitoring and improve decision-making to maintain high efficiency.

Real-time monitoring systems collect data on machine performance, environmental conditions, and product quality. Analyzing this data helps identify trends and potential issues before they cause downtime or quality problems. For example, temperature fluctuations in the reflow oven can be detected and corrected immediately to prevent soldering defects.

5. Optimize Solder Paste Application and Reflow Profiles

Ensure the solder paste printer is calibrated for consistent paste volume and placement accuracy. Variations in solder paste volume can lead to poor solder joints, which compromise product reliability. Regular stencil cleaning and inspection also help maintain print quality.

Optimize reflow oven temperature profiles to prevent solder defects such as bridging or insufficient wetting. Each PCB design and solder paste formulation may require a unique temperature curve, so it is important to develop and validate these profiles carefully. Monitoring the thermal profile during production ensures that the solder paste melts and solidifies correctly, forming strong, reliable joints.

6. Invest in Operator Training and Maintenance

A well-trained workforce is essential for smooth operation. Provide comprehensive training on machine operation, troubleshooting, and preventive maintenance. Skilled operators can quickly identify and resolve issues, minimizing downtime.

Regular machine calibration and maintenance reduce downtime and ensure consistent performance. Scheduled maintenance routines include cleaning, lubrication, and replacement of worn parts. Keeping machines in optimal condition extends their lifespan and maintains production quality.

7. Embrace Continuous Improvement and Feedback Loops

Establish a culture of continuous improvement by regularly reviewing production data and soliciting feedback from operators. Use key performance indicators (KPIs) such as yield rates, cycle times, and defect rates to identify areas for improvement.

Implementing lean manufacturing principles can help eliminate waste and improve efficiency. For example, reducing changeover times between different PCB models can increase line utilization and responsiveness to customer demands.

Benefits of Using a Wholesale PCB SMT Production Machine Line

Enhanced Efficiency and Throughput

Automating the assembly process reduces cycle times and labor costs, enabling manufacturers to produce PCBs at a much faster pace and higher volume. The use of conveyors and automation minimizes manual handling, which further accelerates production. This efficiency is particularly valuable in high-mix, low-volume production environments where flexibility is key.

Improved Quality Control

Integrated inspection systems detect defects early, reducing rework and scrap rates. Consistent solder paste application and precise component placement improve overall product reliability. Real-time monitoring helps maintain quality standards throughout production, ensuring that every PCB meets stringent specifications.

Scalability and Flexibility

Wholesale PCB SMT production lines are modular and customizable, allowing manufacturers to scale production capacity according to demand fluctuations. They can accommodate diverse PCB designs and component types, making them suitable for various industries, including consumer electronics, automotive, industrial, and medical devices.

The flexibility to quickly switch between product types without extensive downtime is a major advantage in today's fast-paced electronics market.

Cost-Effectiveness

Despite the initial investment, these production lines offer long-term savings by reducing labor costs, minimizing material waste, and increasing throughput. Automation also lowers the risk of human error, which can be costly in high-volume manufacturing. Additionally, improved yield rates and reduced defect rates contribute to overall cost savings.

Environmental and Safety Benefits

Automated production lines reduce human exposure to hazardous materials and repetitive strain injuries. Precise control over solder paste and component placement minimizes waste, contributing to more sustainable manufacturing practices.

Innovations Driving the Future of Wholesale PCB SMT Production Machine Lines

The electronics manufacturing industry is rapidly evolving, and wholesale PCB SMT production machine lines are at the forefront of this transformation. Several key innovations are shaping the future:

- Artificial Intelligence and Machine Learning: AI algorithms enable predictive maintenance, optimize process parameters, and improve defect detection. Machine learning models analyze vast amounts of production data to identify subtle patterns that humans might miss, leading to smarter decision-making.

- Advanced Robotics: Enhanced robotic systems increase flexibility and speed in component placement. Collaborative robots (cobots) can work alongside human operators to handle complex tasks, improving efficiency without sacrificing safety.

- Smart Manufacturing and IoT Integration: Real-time data collection and analytics facilitate adaptive control and remote monitoring, driving continuous improvement. IoT sensors embedded throughout the production line provide granular visibility into every stage of the process.

- 3D Printing and Additive Manufacturing: Emerging technologies like 3D printing for PCB prototyping and component fabrication may integrate with SMT lines to accelerate product development cycles.

- Sustainability Initiatives: New materials and processes focused on reducing environmental impact are being incorporated into SMT production lines, aligning with global sustainability goals.

Conclusion

Optimizing your production process with a wholesale PCB SMT production machine line transforms electronics manufacturing by enhancing efficiency, quality, and scalability. By strategically streamlining process flow, leveraging advanced automation, integrating smart manufacturing systems, and investing in workforce training, manufacturers can meet growing market demands while reducing costs and improving product reliability. Embracing the latest innovations ensures that your production line remains competitive and capable of adapting to future challenges in the electronics industry.

A wholesale PCB SMT production machine line is not just an investment in equipment but a comprehensive approach to modern manufacturing excellence. By adopting best practices and continuously improving your processes, you can unlock the full potential of SMT technology and position your business for long-term success.

FAQ

1. What is a wholesale PCB SMT production machine line?

A wholesale PCB SMT production machine line is an automated assembly line that integrates machines such as solder paste printers, pick and place machines, reflow ovens, and inspection systems to efficiently produce printed circuit boards using Surface Mount Technology.

2. How does automation improve PCB production efficiency?

Automation reduces manual labor, minimizes errors, speeds up component placement, and ensures consistent quality, leading to higher throughput and lower production costs.

3. Can a wholesale PCB SMT production line handle different PCB designs?

Yes, these lines are modular and customizable, allowing manufacturers to adapt to various PCB sizes, component types, and production volumes.

4. What role does real-time monitoring play in SMT production?

Real-time monitoring enables early detection of defects, predictive maintenance, and process optimization, which helps maintain high efficiency and product quality.

5. How important is operator training for SMT production lines?

Operator training is crucial for smooth operation, effective troubleshooting, and preventive maintenance, all of which contribute to minimizing downtime and maximizing production efficiency.