Content Menu

● Understanding Surface-Mount Technology (SMT)

>> Benefits of SMT

● The Case for Used SMT Equipment

>> Advantages of Used SMT Equipment

● How to Reduce Costs with Used SMT Equipment

>> 1. Evaluate Your Needs

>> 2. Research and Source Equipment

>> 3. Inspect Equipment Thoroughly

>> 4. Consider Refurbished Equipment

>> 5. Train Your Staff

>> 6. Implement Lean Manufacturing Principles

>> 7. Monitor Performance and Maintenance

● Conclusion

● Frequently Asked Questions

>> 1. What is Surface-Mount Technology (SMT)?

>> 2. How can used SMT equipment save costs?

>> 3. What should I look for when buying used SMT equipment?

>> 4. Is refurbished SMT equipment a good option?

>> 5. How can I ensure my SMT equipment runs efficiently?

In the fast-paced world of electronics manufacturing, cost efficiency is paramount. One of the most effective ways to achieve this is through the use of Surface-Mount Technology (SMT). This article explores how businesses can reduce costs by utilizing used SMT equipment, while also discussing the benefits and considerations involved in this approach.

Understanding Surface-Mount Technology (SMT)

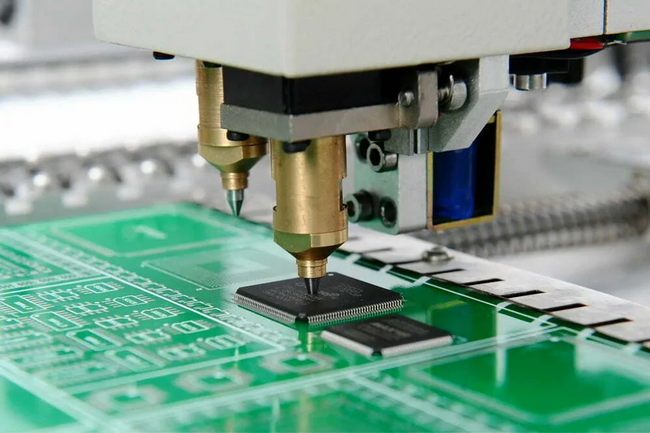

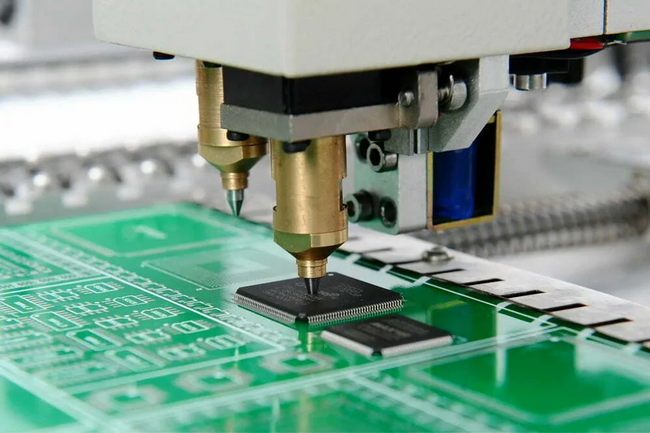

Surface-Mount Technology is a method used to mount electronic components directly onto the surface of printed circuit boards (PCBs). Unlike traditional through-hole technology, which requires components to be inserted into holes drilled in the PCB, SMT allows for a more compact design. This technology has revolutionized the electronics industry by enabling higher component density, reduced manufacturing costs, and improved performance.

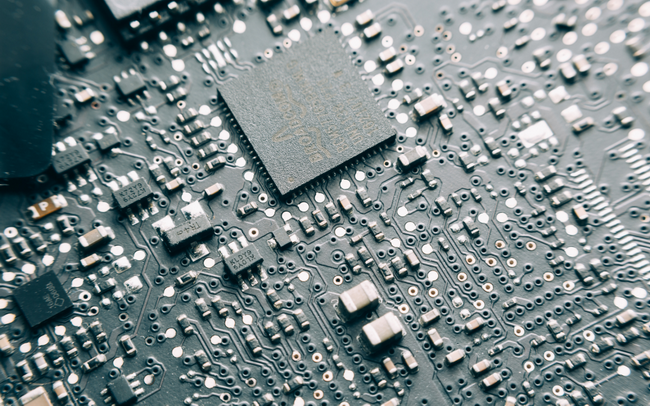

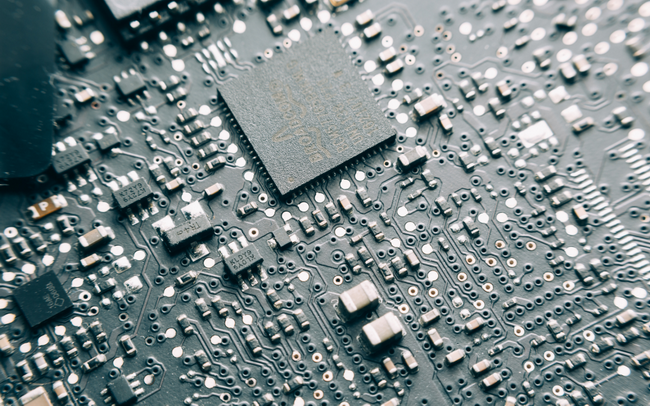

SMT has become the standard in modern electronics manufacturing due to its ability to accommodate the miniaturization of components. As devices become smaller and more complex, the need for efficient space utilization on PCBs has grown. SMT not only meets this demand but also enhances the overall reliability of electronic assemblies by reducing the length of electrical connections, which minimizes signal loss and improves performance.

Benefits of SMT

1. Higher Component Density: SMT allows for smaller components to be placed closer together, which is essential for modern electronic devices that require compact designs. This increased density enables manufacturers to create more sophisticated products without increasing the size of the PCB.

2. Reduced Manufacturing Costs: The automation of SMT processes leads to lower labor costs and faster production times. Automated pick-and-place machines can place thousands of components per hour, significantly speeding up the assembly process compared to manual methods. This efficiency translates into lower overall production costs, making it an attractive option for manufacturers.

3. Improved Performance: SMT components typically have shorter leads, which reduces the distance electrical signals must travel, enhancing performance. This reduction in lead length not only improves signal integrity but also allows for better thermal management, as heat can dissipate more effectively from the components.

The Case for Used SMT Equipment

Investing in new SMT equipment can be a significant financial burden for many companies, especially startups and small manufacturers. Used SMT equipment presents a viable alternative that can help reduce initial capital expenditures while still providing the benefits of modern manufacturing technology.

Advantages of Used SMT Equipment

1. Cost Savings: Used equipment is often available at a fraction of the cost of new machines, allowing companies to allocate resources to other critical areas of their business. This financial flexibility can be crucial for smaller companies looking to grow without overextending their budgets.

2. Immediate Availability: Used equipment can often be purchased and set up more quickly than new machines, which may have long lead times. This immediacy allows manufacturers to ramp up production faster, meeting market demands without delay.

3. Proven Technology: Many used SMT machines have a track record of reliability and performance, making them a safe investment. Established models often come with extensive documentation and support, ensuring that companies can quickly get up to speed with their new equipment.

How to Reduce Costs with Used SMT Equipment

1. Evaluate Your Needs

Before purchasing used SMT equipment, it's essential to assess your specific manufacturing needs. Consider factors such as:

- Production Volume: Determine the volume of production you expect to achieve. This will help you select equipment that can handle your requirements without over-investing. Understanding your production goals will also guide you in choosing the right specifications for your SMT equipment.

- Component Types: Different SMT machines are designed for various types of components. Ensure that the equipment you choose is compatible with the components you plan to use. This compatibility is crucial for maintaining efficiency and quality in your production process.

2. Research and Source Equipment

Finding reliable sources for used SMT equipment is crucial. Look for reputable dealers or auctions that specialize in electronic manufacturing equipment. Online marketplaces and industry-specific forums can also be valuable resources.

When researching, consider reaching out to other manufacturers or industry contacts for recommendations. Networking can provide insights into the best places to find quality used equipment and may even lead to opportunities for direct purchases from other companies looking to upgrade.

3. Inspect Equipment Thoroughly

When considering used SMT equipment, it's vital to conduct a thorough inspection. Check for:

- Operational Condition: Ensure that the equipment is in good working order and has been well-maintained. Request maintenance records and any available warranties to assess the machine's history and reliability.

- Age and Technology: Older machines may not support the latest technology or components, which could limit your production capabilities. Evaluate whether the equipment can accommodate future upgrades or if it will require replacement sooner than expected.

- Availability of Parts: Verify that replacement parts are still available for the equipment you are considering. The ability to source parts easily can significantly impact your maintenance costs and downtime in the future.

4. Consider Refurbished Equipment

Refurbished SMT equipment can offer a middle ground between new and used. These machines have been restored to a like-new condition and often come with warranties, providing peace of mind for your investment.

Refurbished equipment typically undergoes rigorous testing and quality checks, ensuring that it meets industry standards. This option can be particularly appealing for companies that want the reliability of new equipment without the associated costs.

5. Train Your Staff

Investing in training for your staff on how to operate and maintain used SMT equipment can lead to significant cost savings. Proper training ensures that your team can maximize the efficiency of the machines and minimize downtime.

Training programs can cover various aspects, including machine operation, troubleshooting, and routine maintenance. By empowering your staff with knowledge, you can enhance productivity and reduce the likelihood of costly errors during the manufacturing process.

6. Implement Lean Manufacturing Principles

Adopting lean manufacturing principles can further enhance cost savings. Focus on reducing waste, optimizing processes, and improving workflow. This approach can help you get the most out of your used SMT equipment.

Lean principles encourage continuous improvement and efficiency, which can lead to significant reductions in production costs. By analyzing each step of your manufacturing process, you can identify areas for improvement and implement changes that enhance overall productivity.

7. Monitor Performance and Maintenance

Regularly monitor the performance of your SMT equipment to identify any issues early. Implement a maintenance schedule to keep the machines running smoothly, which can prevent costly repairs and downtime.

Utilizing performance metrics can help you track the efficiency of your equipment and identify trends that may indicate the need for maintenance or upgrades. By staying proactive, you can extend the lifespan of your machines and ensure consistent production quality.

Conclusion

Utilizing used Surface-Mount Technology equipment can significantly reduce costs for electronics manufacturers. By carefully evaluating needs, sourcing reliable equipment, and implementing best practices, companies can achieve substantial savings while maintaining high-quality production standards. As the electronics industry continues to evolve, embracing cost-effective solutions like used SMT equipment will be essential for staying competitive.

Frequently Asked Questions

1. What is Surface-Mount Technology (SMT)?

Answer: Surface-Mount Technology (SMT) is a method of mounting electronic components directly onto the surface of printed circuit boards (PCBs), allowing for more compact designs and improved manufacturing efficiency.

2. How can used SMT equipment save costs?

Answer: Used SMT equipment is typically available at a lower price than new machines, reducing initial capital expenditures. Additionally, these machines can still provide the benefits of modern manufacturing technology.

3. What should I look for when buying used SMT equipment?

Answer: When purchasing used SMT equipment, consider the operational condition, age, compatibility with your components, and the availability of replacement parts.

4. Is refurbished SMT equipment a good option?

Answer: Yes, refurbished SMT equipment can be a great option as it is restored to a like-new condition and often comes with warranties, providing additional assurance for your investment.

5. How can I ensure my SMT equipment runs efficiently?

Answer: Regular monitoring of performance, implementing a maintenance schedule, and training staff on proper operation can help ensure that your SMT equipment runs efficiently and minimizes downtime.