Content Menu

● Introduction to Surface-Mount Technology

● 1. Growth of the SMT Market

>> 1.1 Factors Driving Market Growth

● 2. Automation and Robotics in SMT

>> 2.1 Benefits of Automation

● 3. Advancements in Materials

>> 3.1 New Material Innovations

● 4. Integration of Artificial Intelligence

>> 4.1 AI Applications in SMT

● 5. Enhanced Inspection Techniques

>> 5.1 Automated Optical Inspection (AOI)

● 6. Sustainability in SMT

>> 6.1 Eco-Friendly Practices

● 7. The Future of SMT

>> 7.1 Emerging Trends to Watch

● Conclusion

● Frequently Asked Questions

>> 1. What is Surface-Mount Technology (SMT)?

>> 2. What are the main benefits of using SMT?

>> 3. How is automation impacting SMT?

>> 4. What materials are commonly used in SMT?

>> 5. What future trends should we expect in SMT?

Surface-Mount Technology (SMT) has revolutionized the electronics manufacturing industry, enabling the production of smaller, more efficient devices. As we look towards 2025, several trends are emerging that will shape the future of SMT. This article explores these trends, their implications for the industry, and how they will influence the design and manufacturing of electronic components.

Introduction to Surface-Mount Technology

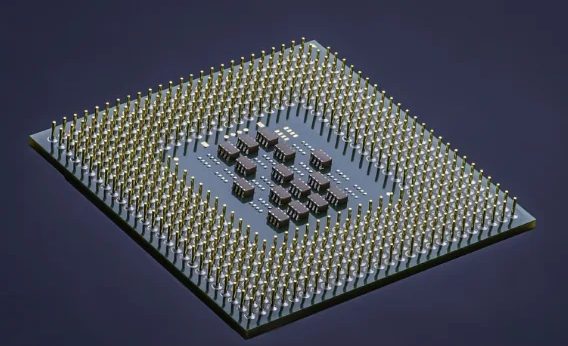

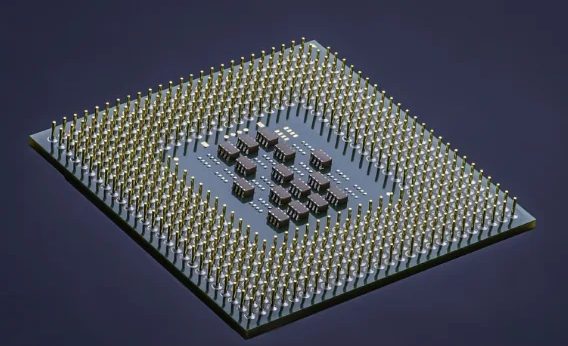

Surface-Mount Technology is a method used to mount electronic components directly onto the surface of printed circuit boards (PCBs). This technique has largely replaced traditional through-hole mounting due to its numerous advantages, including reduced size, improved performance, and lower production costs. SMT allows for a higher density of components on a PCB, which is essential for modern electronic devices that demand compactness and efficiency. As technology advances, SMT continues to evolve, integrating new materials, processes, and automation techniques that enhance its capabilities and applications.

1. Growth of the SMT Market

The global Surface-Mount Technology market is projected to experience significant growth in the coming years. According to recent reports, the market size is expected to reach approximately $6.38 billion by 2025, with a compound annual growth rate (CAGR) of around 9.6% from 2024 to 2025. This growth is driven by several factors, including the increasing demand for consumer electronics, the rise of smart devices, and advancements in manufacturing technologies. The expansion of the SMT market is not only a reflection of the growing electronics sector but also indicates a shift towards more sophisticated manufacturing processes that prioritize efficiency and sustainability.

1.1 Factors Driving Market Growth

- Increased Demand for Consumer Electronics: The proliferation of smartphones, tablets, and wearable devices has led to a surge in demand for compact and efficient electronic components. As consumers seek more functionality in smaller devices, manufacturers are compelled to adopt SMT to meet these expectations.

- Advancements in Manufacturing Technologies: Innovations in SMT equipment and processes are enhancing production efficiency and reducing costs. New technologies, such as advanced soldering techniques and improved placement machines, are enabling manufacturers to produce high-quality products at a faster rate.

- Integration of IoT Devices: The rise of the Internet of Things (IoT) is creating new opportunities for SMT, as more devices require compact and reliable electronic components. IoT applications, ranging from smart home devices to industrial automation, are driving the need for innovative SMT solutions that can support complex functionalities in limited spaces.

2. Automation and Robotics in SMT

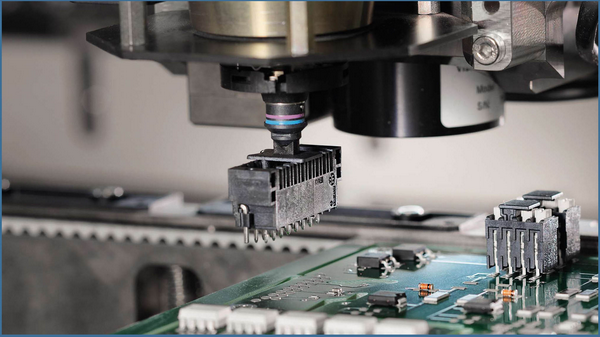

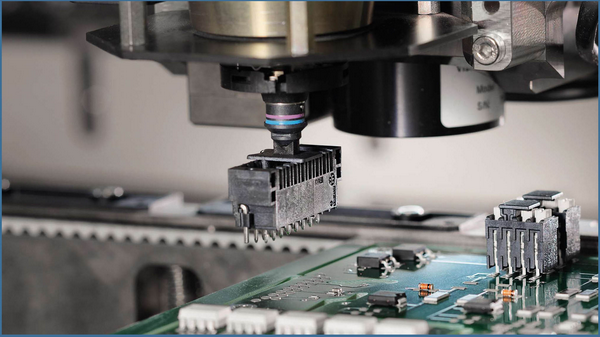

Automation is a key trend in the SMT industry, with manufacturers increasingly adopting robotic systems to enhance production efficiency. Automated assembly processes, including the use of pick-and-place machines, are becoming standard in SMT operations. These machines can quickly and accurately place components on PCBs, significantly reducing the time and labor required for assembly.

2.1 Benefits of Automation

- Increased Precision: Automated systems can place components with high accuracy, reducing the risk of defects. This precision is crucial in SMT, where even minor misalignments can lead to significant performance issues in the final product.

- Higher Throughput: Automation allows for faster production rates, enabling manufacturers to meet growing demand. With the ability to operate continuously and at high speeds, automated systems can significantly increase output without compromising quality.

- Cost Reduction: By minimizing labor costs and reducing waste, automation can significantly lower overall production expenses. This cost efficiency is particularly important in a competitive market where profit margins are often tight.

3. Advancements in Materials

The materials used in SMT are also evolving, with a focus on developing new substrates and soldering materials that enhance performance and reliability. As electronic devices become more complex, the need for advanced materials that can withstand higher temperatures and provide better electrical performance is becoming increasingly important.

3.1 New Material Innovations

- Flexible Substrates: The use of flexible materials is increasing, allowing for the production of bendable and lightweight devices. Flexible substrates enable the creation of innovative designs, such as wearable technology and flexible displays, which are becoming more popular in consumer electronics.

- Lead-Free Solder: As environmental regulations tighten, the adoption of lead-free solder materials is becoming more prevalent, ensuring compliance while maintaining performance. Lead-free solder not only meets regulatory requirements but also offers improved thermal and mechanical properties, making it suitable for high-performance applications.

4. Integration of Artificial Intelligence

Artificial Intelligence (AI) is making its way into SMT processes, providing manufacturers with tools to optimize production and improve quality control. The integration of AI technologies is transforming how SMT operations are managed, leading to smarter manufacturing processes.

4.1 AI Applications in SMT

- Predictive Maintenance: AI can analyze equipment performance data to predict failures before they occur, reducing downtime and maintenance costs. By leveraging machine learning algorithms, manufacturers can implement proactive maintenance strategies that enhance equipment reliability and extend its lifespan.

- Quality Control: Machine learning algorithms can identify defects in real-time, allowing for immediate corrective actions. This capability not only improves product quality but also reduces the likelihood of costly recalls and rework, ultimately enhancing customer satisfaction.

5. Enhanced Inspection Techniques

As SMT components become smaller and more complex, traditional inspection methods are becoming inadequate. New inspection technologies are being developed to ensure quality and reliability, addressing the challenges posed by miniaturization and increased component density.

5.1 Automated Optical Inspection (AOI)

Automated Optical Inspection systems are increasingly used in SMT to detect defects in solder joints and component placements. These systems utilize high-resolution cameras and advanced algorithms to analyze PCBs for quality assurance. AOI technology can quickly identify issues such as misaligned components, insufficient solder, and other defects that could compromise the performance of the final product.

6. Sustainability in SMT

Sustainability is becoming a critical consideration in the SMT industry. Manufacturers are seeking ways to reduce their environmental impact through more sustainable practices. As consumers and regulators alike demand greener solutions, the SMT industry is responding with innovative approaches to minimize waste and energy consumption.

6.1 Eco-Friendly Practices

- Waste Reduction: Implementing lean manufacturing principles can help minimize waste in SMT processes. By optimizing workflows and reducing excess materials, manufacturers can lower their environmental footprint while improving efficiency.

- Recyclable Materials: The use of recyclable materials in PCB production is gaining traction, aligning with global sustainability goals. Manufacturers are increasingly sourcing materials that can be reused or recycled, contributing to a circular economy and reducing the overall environmental impact of electronic waste.

7. The Future of SMT

Looking ahead, the future of Surface-Mount Technology is bright, with continued advancements expected in various areas. The integration of new technologies, materials, and processes will drive innovation and efficiency in the industry. As manufacturers adapt to these trends, they will be better positioned to deliver cutting-edge electronic solutions that meet the demands of an ever-evolving market.

7.1 Emerging Trends to Watch

- 5G Technology: The rollout of 5G networks will create new opportunities for SMT, as devices will require advanced components to support higher data rates. The demand for high-frequency components and improved signal integrity will drive innovation in SMT design and manufacturing.

- Wearable Technology: The demand for wearable devices will continue to grow, pushing the boundaries of SMT in terms of size and functionality. As consumers seek more features in compact designs, manufacturers will need to leverage SMT to create innovative solutions that meet these needs.

Conclusion

Surface-Mount Technology is at the forefront of the electronics manufacturing industry, and its evolution is set to continue in 2025 and beyond. With advancements in automation, materials, and AI integration, SMT will play a crucial role in meeting the demands of an increasingly connected world. As manufacturers adapt to these trends, they will be better positioned to deliver innovative and efficient electronic solutions that enhance the user experience and drive technological progress.

Frequently Asked Questions

1. What is Surface-Mount Technology (SMT)?

Answer: Surface-Mount Technology is a method of mounting electronic components directly onto the surface of printed circuit boards, allowing for smaller and more efficient designs. This technique has become the standard in modern electronics manufacturing due to its numerous advantages over traditional methods.

2. What are the main benefits of using SMT?

Answer: The main benefits of SMT include reduced size and weight of electronic devices, lower production costs, and improved performance and reliability. SMT enables higher component density, which is essential for the compact designs required in today's electronic devices.

3. How is automation impacting SMT?

Answer: Automation is enhancing SMT by increasing production speed, improving precision, and reducing labor costs through the use of robotic systems and automated assembly processes. This shift towards automation allows manufacturers to scale operations efficiently while maintaining high quality.

4. What materials are commonly used in SMT?

Answer: Common materials in SMT include flexible substrates, lead-free solder, and various types of electronic components designed for surface mounting. The choice of materials is critical for ensuring the performance and reliability of the final product.

5. What future trends should we expect in SMT?

Answer: Future trends in SMT include the integration of AI for quality control, advancements in inspection techniques, and the continued growth of IoT and wearable technology. These trends will drive innovation and efficiency in the SMT industry, shaping the future of electronics manufacturing.