Content Menu

● Introduction to Surface-Mount Technology

● Common Challenges in Surface-Mount Technology

>> 1. Soldering Issues

>> 2. Component Placement Accuracy

>> 3. Thermal Management

>> 4. Design Complexity

>> 5. Material Compatibility

>> 6. Inspection and Testing Challenges

>> 7. Supply Chain Issues

● Solutions to Overcome SMT Challenges

>> 1. Improving Soldering Techniques

>> 2. Enhancing Component Placement Accuracy

>> 3. Effective Thermal Management

>> 4. Simplifying PCB Design

>> 5. Ensuring Material Compatibility

>> 6. Implementing Robust Inspection and Testing

>> 7. Strengthening Supply Chain Management

● Conclusion

● Frequently Asked Questions

>> 1. What is Surface-Mount Technology (SMT)?

>> 2. What are the common soldering issues in SMT?

>> 3. How can companies improve component placement accuracy?

>> 4. What are the thermal management challenges in SMT?

>> 5. How can inspection and testing be enhanced in SMT processes?

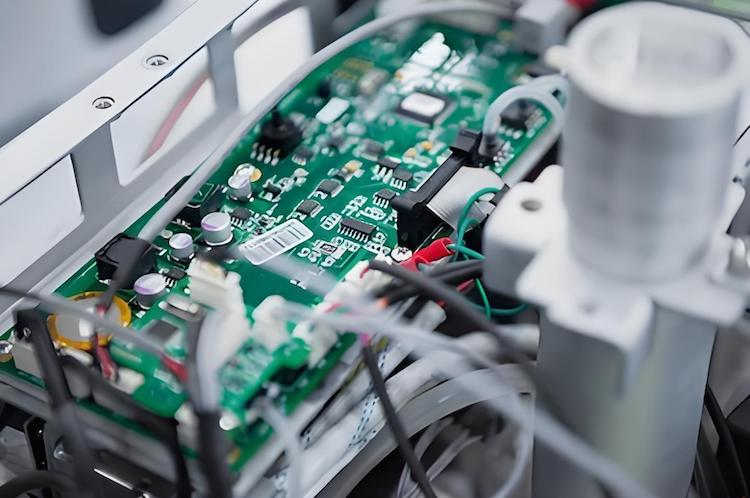

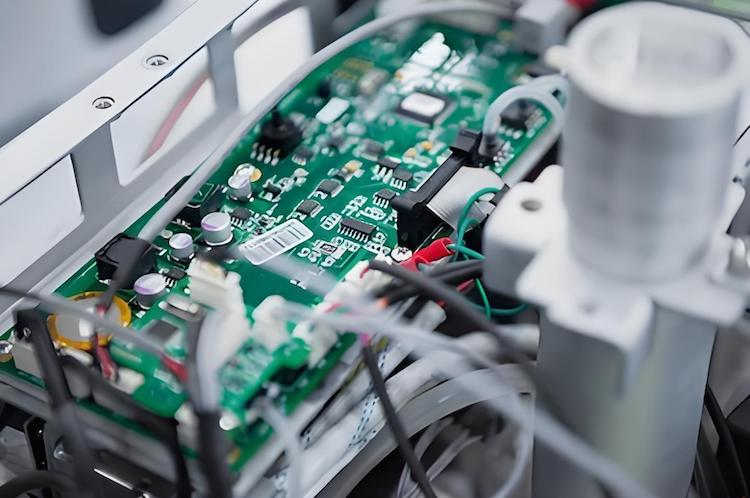

Surface-Mount Technology (SMT) has revolutionized the electronics manufacturing industry by allowing for the efficient assembly of components onto printed circuit boards (PCBs). This method has become the standard in modern electronics due to its numerous advantages, including reduced size and weight of electronic devices, improved performance, and lower manufacturing costs. However, despite its advantages, companies face several challenges when implementing SMT. This article explores these challenges in detail, providing insights into the complexities of SMT and potential solutions.

Introduction to Surface-Mount Technology

Surface-Mount Technology involves mounting electronic components directly onto the surface of PCBs. This method contrasts with traditional through-hole technology, where components are inserted into holes in the PCB. SMT offers numerous benefits, such as the ability to create smaller and lighter devices, which is essential in today's fast-paced technological landscape. The miniaturization of components allows for more compact designs, enabling manufacturers to produce devices that are not only more efficient but also more appealing to consumers. However, the transition to SMT is not without its hurdles, as the complexity of the technology can lead to various challenges that manufacturers must address.

Common Challenges in Surface-Mount Technology

1. Soldering Issues

One of the most significant challenges in SMT is related to soldering. The soldering process is critical for ensuring reliable electrical connections between components and the PCB. Common soldering issues include:

- Cold Solder Joints: These occur when the solder does not melt properly, leading to poor electrical connections. This can be caused by insufficient heating during the reflow process. Cold solder joints can result in intermittent connections, which may lead to device failures in the field, causing significant warranty costs and customer dissatisfaction.

- Solder Bridging: Excess solder can create unintended connections between adjacent pads, leading to short circuits. This is particularly problematic with smaller components where space is limited. Solder bridging not only affects the functionality of the device but can also complicate the manufacturing process, as rework is often required to correct these issues.

2. Component Placement Accuracy

Accurate placement of components is crucial in SMT. Misalignment can lead to several issues, including:

- Increased Defect Rates: Misplaced components can result in functional failures, requiring rework or scrapping of the PCB. This not only increases production costs but also extends lead times, which can be detrimental in a competitive market.

- Incompatibility with Automated Equipment: As components become smaller and more complex, ensuring that automated pick-and-place machines can handle them accurately becomes increasingly challenging. The precision required for placing tiny components can strain existing machinery, necessitating upgrades or replacements to maintain quality standards.

3. Thermal Management

Thermal management is another critical challenge in SMT. Components generate heat during operation, and improper heat dissipation can lead to:

- Overheating: This can damage components and affect the overall reliability of the device. Overheating can lead to catastrophic failures, where components may burn out or become permanently damaged, resulting in costly recalls and repairs.

- Thermal Cycling: Repeated heating and cooling can cause mechanical stress on solder joints, leading to failures over time. This is particularly concerning in applications where devices are subjected to varying environmental conditions, such as automotive or aerospace applications.

4. Design Complexity

As electronic devices become more sophisticated, the design of PCBs also becomes more complex. Challenges include:

- Increased Density: Higher component density can lead to difficulties in solder paste application and component placement. As designs become more compact, the risk of defects increases, necessitating more rigorous quality control measures.

- Layer Count: Multi-layer PCBs can complicate the manufacturing process, making it harder to achieve consistent quality. The more layers a PCB has, the more challenging it becomes to ensure that all connections are made correctly, which can lead to increased testing times and costs.

5. Material Compatibility

The materials used in SMT can also pose challenges. Issues include:

- Solder Paste Quality: Poor-quality solder paste can lead to defects such as insufficient wetting or poor adhesion. The choice of solder paste is critical, as it must be compatible with both the components and the PCB materials to ensure reliable connections.

- Component Material Compatibility: Different materials can react adversely during the soldering process, affecting the integrity of the connections. Understanding the thermal and chemical properties of materials used in SMT is essential for preventing issues that could compromise device performance.

6. Inspection and Testing Challenges

Ensuring the quality of SMT assemblies requires effective inspection and testing methods. Common challenges include:

- Hidden Defects: Defects that are not visible on the surface can be difficult to detect, especially in densely packed assemblies. These hidden defects can lead to failures that only become apparent after the product has been deployed, resulting in costly repairs and damage to brand reputation.

- Limited Accessibility: The close proximity of components can hinder the ability of inspection equipment to access all areas of the PCB. This limitation can make it challenging to perform thorough inspections, increasing the risk of defective products reaching the market.

7. Supply Chain Issues

The global supply chain for electronic components can be unpredictable. Challenges include:

- Component Shortages: Fluctuations in supply can lead to delays in production and increased costs. Companies may find themselves scrambling to find alternative suppliers or redesigning products to accommodate available components, which can disrupt timelines and budgets.

- Quality Variability: Sourcing components from different suppliers can result in variations in quality, affecting the overall reliability of the final product. Maintaining consistent quality across different batches of components is crucial for ensuring product reliability and customer satisfaction.

Solutions to Overcome SMT Challenges

1. Improving Soldering Techniques

To address soldering issues, companies can:

- Optimize Reflow Profiles: Adjusting the temperature and time settings in the reflow oven can help ensure proper solder melting and adhesion. By fine-tuning these parameters, manufacturers can reduce the incidence of cold solder joints and improve overall solder quality.

- Use Advanced Soldering Materials: Employing high-quality solder paste and flux can reduce the likelihood of cold joints and bridging. Advanced materials can also enhance the reliability of solder joints, particularly in high-stress applications.

2. Enhancing Component Placement Accuracy

To improve placement accuracy, companies can:

- Invest in Advanced Equipment: Upgrading to more precise pick-and-place machines can enhance placement accuracy and reduce defects. Investing in state-of-the-art technology can lead to significant long-term savings by minimizing rework and improving yield rates.

- Implement Vision Systems: Using cameras and sensors can help verify component placement in real-time. These systems can detect misalignments and provide feedback to operators, allowing for immediate corrections.

3. Effective Thermal Management

To manage heat effectively, companies can:

- Design for Thermal Dissipation: Incorporating heat sinks and thermal vias can help dissipate heat more effectively. Proper thermal management is essential for maintaining the longevity and reliability of electronic devices.

- Monitor Operating Temperatures: Implementing temperature monitoring systems can help identify overheating issues before they lead to failures. Real-time monitoring can provide valuable data for optimizing thermal management strategies.

4. Simplifying PCB Design

To address design complexity, companies can:

- Utilize Design Software: Advanced PCB design software can help optimize layouts for component placement and thermal management. These tools can simulate various scenarios, allowing designers to identify potential issues before production.

- Conduct Design Reviews: Regular design reviews can help identify potential issues before they become problematic. Collaborative reviews involving cross-functional teams can lead to more robust designs and improved manufacturability.

5. Ensuring Material Compatibility

To mitigate material compatibility issues, companies can:

- Conduct Compatibility Testing: Testing different materials together can help identify potential issues before production. Understanding how materials interact during the soldering process is crucial for preventing defects.

- Standardize Materials: Using standardized materials across different products can reduce variability and improve quality. Standardization can simplify procurement and ensure consistent performance across product lines.

6. Implementing Robust Inspection and Testing

To enhance inspection and testing processes, companies can:

- Adopt Automated Inspection Systems: Automated Optical Inspection (AOI) and X-ray inspection can help detect hidden defects more effectively. These technologies can significantly improve the reliability of quality control processes.

- Establish Quality Control Protocols: Implementing strict quality control measures can help ensure that defects are identified and addressed promptly. Regular audits and process evaluations can help maintain high standards.

7. Strengthening Supply Chain Management

To address supply chain challenges, companies can:

- Diversify Suppliers: Sourcing components from multiple suppliers can reduce the risk of shortages and improve quality consistency. Building strong relationships with suppliers can also enhance communication and responsiveness.

- Implement Inventory Management Systems: Effective inventory management can help ensure that components are available when needed, reducing production delays. Utilizing just-in-time inventory practices can help minimize excess stock and associated costs.

Conclusion

Surface-Mount Technology offers significant advantages in electronics manufacturing, but it also presents a range of challenges that companies must navigate. By understanding these challenges and implementing effective solutions, manufacturers can enhance the reliability and efficiency of their SMT processes, ultimately leading to better products and increased customer satisfaction. As the industry continues to evolve, staying ahead of these challenges will be crucial for maintaining a competitive edge.

Frequently Asked Questions

1. What is Surface-Mount Technology (SMT)?

Answer: Surface-Mount Technology (SMT) is a method of mounting electronic components directly onto the surface of printed circuit boards (PCBs), allowing for smaller and more efficient designs.

2. What are the common soldering issues in SMT?

Answer: Common soldering issues include cold solder joints, solder bridging, and insufficient wetting, which can lead to poor electrical connections and device failures.

3. How can companies improve component placement accuracy?

Answer: Companies can improve placement accuracy by investing in advanced pick-and-place machines and implementing vision systems for real-time verification of component placement.

4. What are the thermal management challenges in SMT?

Answer: Thermal management challenges include overheating of components and thermal cycling, which can lead to mechanical stress and failures in solder joints.

5. How can inspection and testing be enhanced in SMT processes?

Answer: Inspection and testing can be enhanced by adopting automated inspection systems like AOI and X-ray inspection, as well as establishing strict quality control protocols.