Content Menu

● Understanding SMT Consumables

>> What Are SMT Consumables?

>> Importance of Quality in SMT Consumables

● Enhancing Manufacturing Efficiency with High-Quality SMT Consumables

>> 1. Improved Adhesion and Reliability

>> 2. Reduced Defect Rates

>> 3. Enhanced Process Speed

>> 4. Lower Maintenance Costs

>> 5. Consistency in Production

>> 6. Better Thermal Performance

>> 7. Streamlined Supply Chain Management

● The Role of Training and Best Practices

● Conclusion

● Frequently Asked Questions

>> 1. What are the main types of SMT consumables?

>> 2. How do high-quality SMT consumables affect production costs?

>> 3. Can using low-quality SMT consumables impact product reliability?

>> 4. What role does training play in the effective use of SMT consumables?

>> 5. How can manufacturers choose the right SMT consumables?

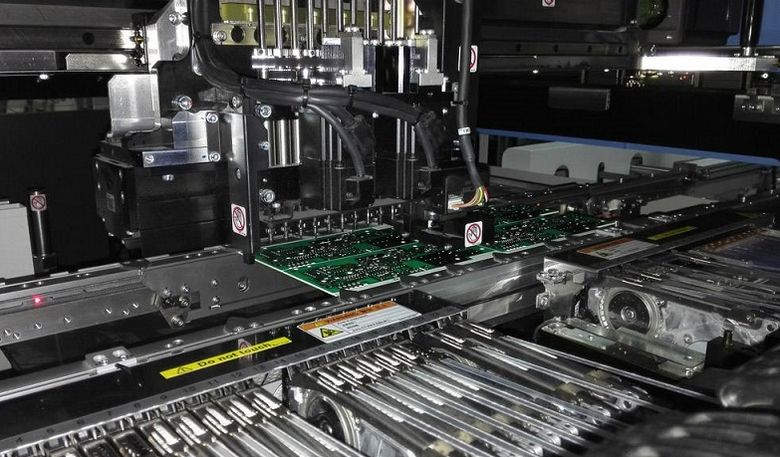

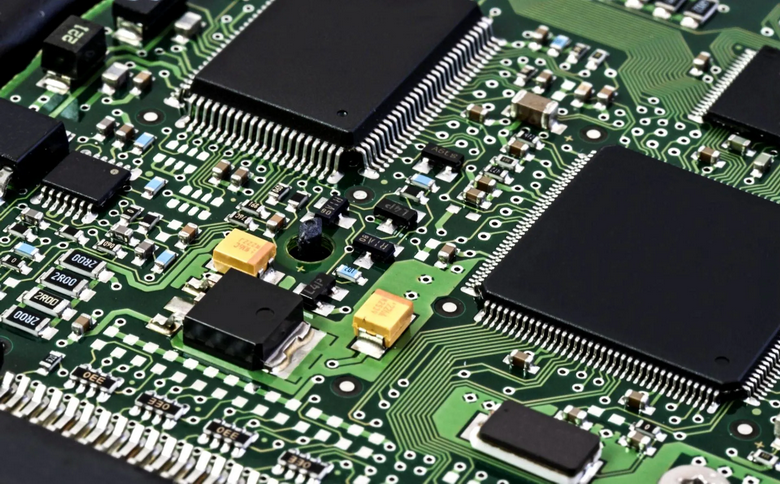

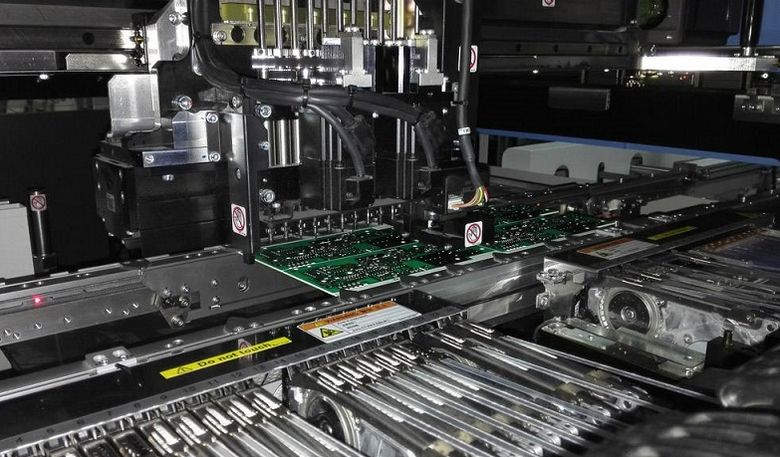

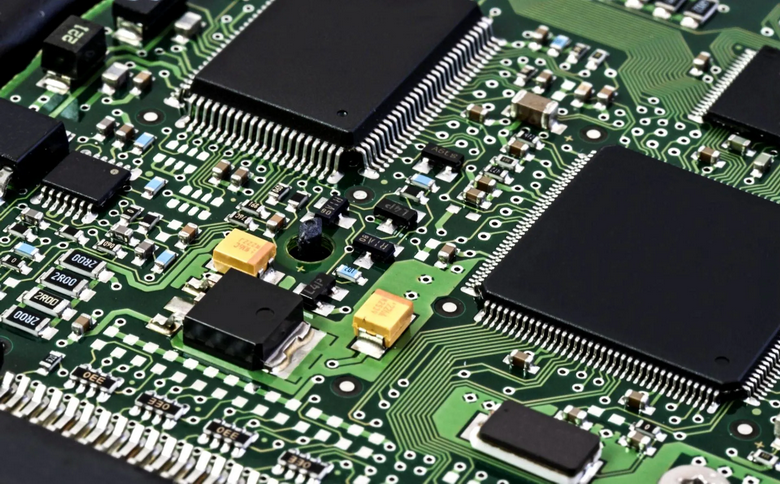

In the fast-paced world of electronics manufacturing, Surface Mount Technology (SMT) has become a cornerstone for producing high-quality printed circuit boards (PCBs). A critical aspect of SMT production is the use of high-quality SMT consumables. These consumables, which include solder paste, adhesives, and various other materials, play a significant role in enhancing manufacturing efficiency. This article explores how investing in high-quality SMT consumables can lead to improved production processes, reduced costs, and higher product quality.

Understanding SMT Consumables

What Are SMT Consumables?

SMT consumables are materials used in the SMT assembly process. They include:

- Solder Paste: A mixture of solder powder and flux used to attach components to PCBs. The quality of solder paste can significantly affect the soldering process, influencing the strength and reliability of the connections.

- Adhesives: Used to secure components in place before soldering. High-quality adhesives ensure that components remain fixed during the soldering process, preventing misalignment and ensuring optimal performance.

- Stencil: A template used to apply solder paste accurately. The precision of the stencil affects the amount of solder paste applied, which is crucial for achieving the right solder joint quality.

- Cleaning Agents: Used to clean PCBs and equipment to ensure optimal performance. Effective cleaning agents remove residues that can interfere with soldering and component placement, contributing to a more efficient production process.

- Nozzles and Feeders: Components that help in the precise placement of electronic components. The quality of these parts can influence the speed and accuracy of component placement, which is vital for maintaining high production rates.

Importance of Quality in SMT Consumables

The quality of SMT consumables directly impacts the efficiency of the manufacturing process. High-quality materials ensure better adhesion, reduce defects, and enhance the overall reliability of the final product. Conversely, low-quality consumables can lead to increased waste, higher defect rates, and ultimately, greater costs. Investing in quality not only improves immediate production outcomes but also contributes to long-term sustainability and profitability.

Enhancing Manufacturing Efficiency with High-Quality SMT Consumables

1. Improved Adhesion and Reliability

High-quality solder paste and adhesives provide better adhesion properties, which are crucial for the reliability of electronic components. When components are securely attached to the PCB, the risk of failure during operation decreases significantly. This reliability translates into fewer returns and repairs, enhancing overall efficiency. Moreover, reliable adhesion ensures that components can withstand thermal cycling and mechanical stress, which are common in electronic devices. This durability is particularly important in applications where devices are subjected to harsh environments.

2. Reduced Defect Rates

Using high-quality SMT consumables minimizes defects such as solder bridging, insufficient solder, and component misalignment. These defects can lead to costly rework and delays in production. By investing in superior materials, manufacturers can reduce the likelihood of defects, ensuring a smoother production process. Additionally, lower defect rates contribute to higher customer satisfaction, as products are more likely to meet quality standards and perform reliably in the field. This not only enhances the manufacturer's reputation but also fosters customer loyalty.

3. Enhanced Process Speed

High-quality consumables often allow for faster processing times. For instance, solder pastes with optimal viscosity can be printed more quickly and accurately, reducing cycle times. This speed is crucial in meeting production deadlines and increasing throughput. Faster processing also means that manufacturers can respond more effectively to market demands, allowing for greater flexibility in production schedules. As a result, companies can capitalize on new opportunities and maintain a competitive edge in the market.

4. Lower Maintenance Costs

Quality SMT consumables can lead to less wear and tear on machinery. For example, using high-quality nozzles and feeders reduces the likelihood of jams and misfeeds, which can cause downtime. This reduction in maintenance needs translates to lower operational costs and improved efficiency. Furthermore, well-maintained equipment operates more reliably, which is essential for maintaining consistent production levels. By minimizing maintenance issues, manufacturers can focus on optimizing their production processes rather than dealing with unexpected equipment failures.

5. Consistency in Production

High-quality SMT consumables provide consistent results, which is essential for maintaining quality standards. Consistency in solder paste application and component placement ensures that each PCB meets the required specifications, reducing variability in the final product. This uniformity is critical in industries where precision is paramount, such as aerospace and medical devices. By ensuring that every product meets the same high standards, manufacturers can build trust with their customers and reduce the risk of costly recalls or warranty claims.

6. Better Thermal Performance

High-quality solder materials often have superior thermal properties, which can enhance the performance of the final product. This is particularly important in applications where heat dissipation is critical. Improved thermal performance can lead to longer product lifespans and better overall functionality. For instance, devices that operate at lower temperatures tend to have increased reliability and reduced risk of failure. This is especially relevant in high-performance applications, such as automotive electronics and telecommunications equipment.

7. Streamlined Supply Chain Management

Investing in high-quality SMT consumables can also streamline supply chain management. Reliable suppliers of quality materials often provide better support and faster delivery times, which can help manufacturers maintain production schedules and reduce lead times. A well-managed supply chain ensures that manufacturers have the necessary materials on hand when needed, preventing delays and disruptions in production. Additionally, strong relationships with suppliers can lead to better pricing and terms, further enhancing overall efficiency.

The Role of Training and Best Practices

While high-quality SMT consumables are essential, their effectiveness can be further enhanced through proper training and adherence to best practices. Operators should be trained on the correct handling and application of these materials to maximize their benefits. Implementing standard operating procedures (SOPs) can also help ensure that the use of consumables is optimized throughout the production process. Regular training sessions and updates on new technologies can keep the workforce informed and skilled, leading to continuous improvement in manufacturing efficiency.

Conclusion

In conclusion, high-quality SMT consumables are vital for improving manufacturing efficiency in the electronics industry. By investing in superior materials, manufacturers can enhance product reliability, reduce defect rates, and streamline their production processes. The benefits of using high-quality SMT consumables extend beyond immediate production efficiency, contributing to long-term cost savings and improved product quality. As the electronics market continues to evolve, the importance of quality in SMT consumables will only grow, making it a critical focus for manufacturers aiming to succeed in a competitive landscape.

Frequently Asked Questions

1. What are the main types of SMT consumables?

Answer: The main types of SMT consumables include solder paste, adhesives, stencils, cleaning agents, and nozzles.

2. How do high-quality SMT consumables affect production costs?

Answer: High-quality SMT consumables reduce defect rates and rework, leading to lower production costs and improved profitability.

3. Can using low-quality SMT consumables impact product reliability?

Answer: Yes, low-quality consumables can lead to defects and failures, negatively impacting product reliability and increasing warranty claims.

4. What role does training play in the effective use of SMT consumables?

Answer: Training ensures that operators understand how to handle and apply SMT consumables correctly, maximizing their benefits and minimizing waste.

5. How can manufacturers choose the right SMT consumables?

Answer: Manufacturers should evaluate suppliers based on quality certifications, product performance, and customer support to choose the right SMT consumables.