Content Menu

● Introduction to Surface-Mount Technology

● The Evolution of SMT

>> Historical Background

>> Key Milestones

● Advantages of Surface-Mount Technology

>> 1. Increased Component Density

>> 2. Enhanced Manufacturing Efficiency

>> 3. Cost-Effectiveness

>> 4. Improved Reliability

>> 5. Flexibility in Design

● Applications of Surface-Mount Technology

>> 1. Consumer Electronics

>> 2. Automotive Industry

>> 3. Medical Devices

>> 4. Telecommunications

>> 5. Industrial Equipment

● The Future of Surface-Mount Technology

>> 1. Miniaturization

>> 2. Advanced Materials

>> 3. Integration with IoT

>> 4. Sustainability

● Conclusion

● Frequently Asked Questions

>> 1. What is Surface-Mount Technology (SMT)?

>> 2. What are the advantages of using SMT over traditional through-hole technology?

>> 3. In which industries is SMT commonly used?

>> 4. How does SMT contribute to the miniaturization of electronic devices?

>> 5. What trends are shaping the future of Surface-Mount Technology?

Surface-Mount Technology (SMT) has revolutionized the landscape of electronics assembly, becoming a cornerstone of modern manufacturing processes. This article delves into the significance of SMT, its advantages, applications, and the future of electronics assembly.

Introduction to Surface-Mount Technology

Surface-Mount Technology refers to a method of mounting electronic components directly onto the surface of printed circuit boards (PCBs). Unlike traditional through-hole technology, where components are inserted into holes drilled in the PCB, SMT allows for a more compact and efficient design. This technology has gained immense popularity since its inception in the 1960s, primarily due to its ability to facilitate the production of smaller, lighter, and more powerful electronic devices. The shift towards SMT has not only transformed manufacturing processes but has also enabled the development of innovative products that meet the ever-increasing demands of consumers for portability and functionality.

The Evolution of SMT

Historical Background

The development of SMT began in the 1960s, driven by the need for more efficient manufacturing processes in the electronics industry. Initially, SMT was met with skepticism, as traditional through-hole methods dominated the market. However, by the late 1980s and early 1990s, SMT began to gain traction, accounting for a significant portion of electronic assemblies. The introduction of automated assembly techniques further propelled its adoption, making it the preferred choice for manufacturers. This evolution was marked by a gradual acceptance of SMT as a viable alternative, leading to a paradigm shift in how electronic devices were designed and produced.

Key Milestones

1. Introduction of SMDs: Surface-Mount Devices (SMDs) were developed to complement SMT, allowing for a more streamlined assembly process. These devices are specifically designed for SMT, featuring flat leads that can be easily soldered onto the PCB surface, thus enhancing the efficiency of the assembly process.

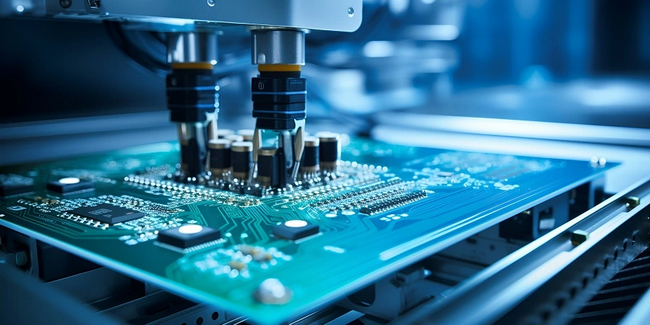

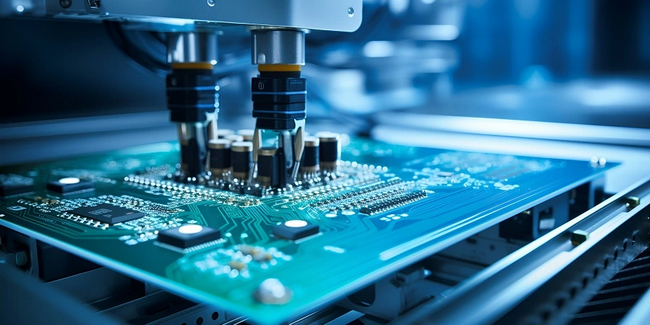

2. Advancements in Automation: The rise of automated pick-and-place machines significantly increased the speed and accuracy of SMT assembly. These machines can quickly and precisely place thousands of components per hour, drastically reducing assembly time and labor costs.

3. Miniaturization Trends: As consumer demand for smaller devices grew, SMT evolved to accommodate increasingly compact designs. This trend has led to the creation of ultra-thin smartphones, wearables, and other portable electronics that fit seamlessly into modern lifestyles.

Advantages of Surface-Mount Technology

1. Increased Component Density

One of the primary advantages of SMT is its ability to accommodate a higher density of components on a PCB. This is achieved by eliminating the need for through-holes, allowing for more components to be placed in a given area. As a result, manufacturers can create smaller and more complex devices without compromising performance. This increased density not only enhances the functionality of devices but also allows for more sophisticated designs that can integrate advanced features such as wireless connectivity and high-resolution displays.

2. Enhanced Manufacturing Efficiency

SMT significantly improves manufacturing efficiency. Automated assembly processes reduce the time required for assembly, leading to faster production cycles. Additionally, the use of reflow soldering techniques allows for simultaneous soldering of multiple components, further streamlining the process. This efficiency translates into shorter lead times for product development and the ability to respond quickly to market demands, giving manufacturers a competitive edge.

3. Cost-Effectiveness

The automation of SMT assembly reduces labor costs and minimizes the risk of human error. Furthermore, the compact nature of SMT allows for savings in materials and shipping costs, as smaller devices require less packaging and transportation space. This cost-effectiveness is particularly beneficial for high-volume production runs, where even small savings per unit can lead to significant overall reductions in manufacturing expenses.

4. Improved Reliability

SMT components are generally more reliable than their through-hole counterparts. The solder joints created during the reflow process are less prone to mechanical stress, resulting in enhanced durability and longevity of the final product. This reliability is crucial in applications where device failure can have serious consequences, such as in medical devices or automotive systems.

5. Flexibility in Design

SMT provides designers with greater flexibility in creating innovative products. The ability to place components on both sides of the PCB allows for more intricate designs and functionalities, catering to the evolving needs of consumers. This flexibility enables the integration of various technologies, such as sensors and microcontrollers, into compact devices, paving the way for advancements in fields like IoT and smart technology.

Applications of Surface-Mount Technology

1. Consumer Electronics

SMT is widely used in the production of consumer electronics, including smartphones, tablets, and laptops. The demand for compact and lightweight devices has driven manufacturers to adopt SMT for its ability to facilitate miniaturization. As a result, consumers benefit from devices that are not only smaller but also more powerful, offering enhanced performance and features.

2. Automotive Industry

In the automotive sector, SMT plays a crucial role in the development of advanced driver-assistance systems (ADAS), infotainment systems, and electric vehicle components. The reliability and compactness of SMT make it ideal for automotive applications, where space and performance are critical. As vehicles become increasingly equipped with sophisticated electronics, SMT will continue to be integral in ensuring that these systems function effectively and safely.

3. Medical Devices

The medical industry has also embraced SMT, utilizing it in the production of diagnostic equipment, wearable health monitors, and other medical devices. The precision and reliability of SMT are essential in ensuring the safety and effectiveness of medical technologies. As healthcare continues to evolve towards more personalized and remote monitoring solutions, SMT will play a vital role in enabling the development of innovative medical devices that improve patient outcomes.

4. Telecommunications

Telecommunication devices, such as routers and switches, benefit from SMT's ability to support high-density component placement. This is particularly important in the development of high-speed communication systems that require efficient and reliable performance. As the demand for faster and more reliable internet connectivity grows, SMT will be crucial in supporting the infrastructure needed to meet these demands.

5. Industrial Equipment

SMT is increasingly used in industrial applications, including automation systems and control devices. The robustness and efficiency of SMT make it suitable for environments where reliability is paramount. As industries continue to adopt automation and smart technologies, SMT will be essential in facilitating the development of advanced industrial equipment that enhances productivity and efficiency.

The Future of Surface-Mount Technology

As technology continues to advance, the role of SMT in electronics assembly is expected to grow. Key trends shaping the future of SMT include:

1. Miniaturization

The push for smaller and more powerful devices will continue to drive the development of SMT. Innovations in component design and manufacturing techniques will enable even greater miniaturization, allowing for the creation of ultra-compact electronic assemblies. This trend will likely lead to the emergence of new applications and markets, particularly in areas such as wearable technology and smart home devices.

2. Advanced Materials

The use of advanced materials in SMT will enhance the performance and reliability of electronic devices. Research into new solder materials and substrates will contribute to the ongoing evolution of SMT. These advancements will not only improve the durability of devices but also enable the development of new functionalities, such as improved thermal management and enhanced signal integrity.

3. Integration with IoT

The rise of the Internet of Things (IoT) will further expand the applications of SMT. As more devices become interconnected, the demand for compact and efficient electronics will increase, positioning SMT as a key player in this transformation. The ability to integrate sensors, communication modules, and processing units into small form factors will be essential in realizing the full potential of IoT technologies.

4. Sustainability

Sustainability will become a critical consideration in SMT manufacturing processes. Efforts to reduce waste, improve energy efficiency, and utilize eco-friendly materials will shape the future of SMT in the electronics industry. As consumers and regulators increasingly prioritize sustainability, manufacturers will need to adopt practices that minimize environmental impact while maintaining high-quality production standards.

Conclusion

Surface-Mount Technology has fundamentally transformed the way electronic devices are designed and manufactured. Its advantages in terms of component density, manufacturing efficiency, cost-effectiveness, reliability, and design flexibility make it an indispensable part of modern electronics assembly. As technology continues to evolve, SMT will play an increasingly vital role in shaping the future of the electronics industry, driving innovation and enabling the development of next-generation devices that meet the demands of a rapidly changing world.

Frequently Asked Questions

1. What is Surface-Mount Technology (SMT)?

Answer: Surface-Mount Technology (SMT) is a method of mounting electronic components directly onto the surface of printed circuit boards (PCBs), allowing for more compact and efficient designs.

2. What are the advantages of using SMT over traditional through-hole technology?

Answer: SMT offers increased component density, enhanced manufacturing efficiency, cost-effectiveness, improved reliability, and greater design flexibility compared to traditional through-hole technology.

3. In which industries is SMT commonly used?

Answer: SMT is widely used in consumer electronics, automotive, medical devices, telecommunications, and industrial equipment.

4. How does SMT contribute to the miniaturization of electronic devices?

Answer: SMT allows for a higher density of components on a PCB, enabling the production of smaller and more complex devices without compromising performance.

5. What trends are shaping the future of Surface-Mount Technology?

Answer: Key trends include miniaturization, the use of advanced materials, integration with IoT, and a focus on sustainability in manufacturing processes.