Content Menu

● Understanding Double-Sided PCB Assembly

● Key Advantages of Double-Sided PCB Assembly

>> Increased Circuit Density and Compact Design

>> Enhanced Electrical Performance and Signal Integrity

>> Superior Thermal Management

>> Cost-Effectiveness and Production Efficiency

>> Design Flexibility and Versatility

● Applications of Double-Sided PCB Assembly

● The Role of Wholesale PCB SMT Assembly Double Sided Services

● Future Trends in Double-Sided PCB Assembly

● Conclusion

● FAQ

>> 1. What is the main difference between single-sided and double-sided PCB assembly?

>> 2. Why is double-sided PCB assembly preferred for compact electronic devices?

>> 3. How does double-sided PCB assembly improve thermal management?

>> 4. What role does wholesale PCB SMT assembly double sided play in manufacturing?

>> 5. Can double-sided PCBs be used in high-frequency applications?

In the rapidly evolving world of electronics, the demand for smaller, faster, and more efficient devices continues to grow. This trend has driven significant advancements in printed circuit board (PCB) technology, with double-sided PCB assembly emerging as a cornerstone for modern electronic manufacturing. Double-sided PCBs, featuring conductive copper layers on both sides, provide critical advantages that single-sided boards cannot match. This article explores why double-sided PCB assembly is essential for contemporary electronics, highlighting its benefits, applications, and the role of wholesale PCB SMT assembly double sided services in meeting industry needs.

Understanding Double-Sided PCB Assembly

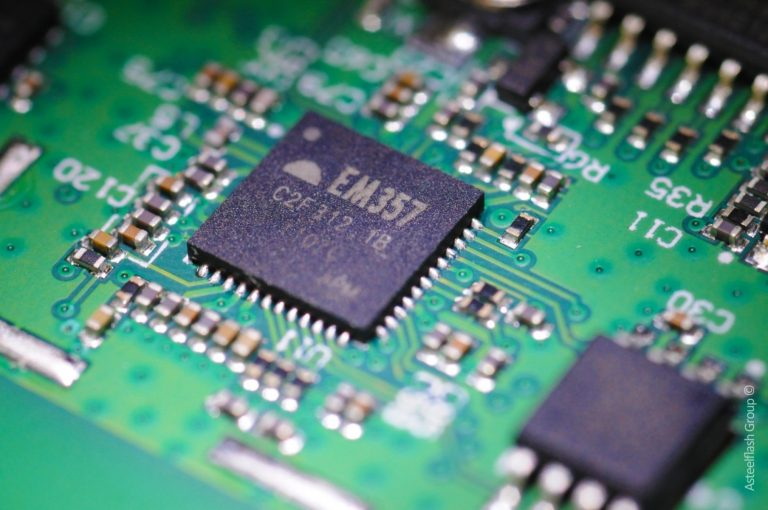

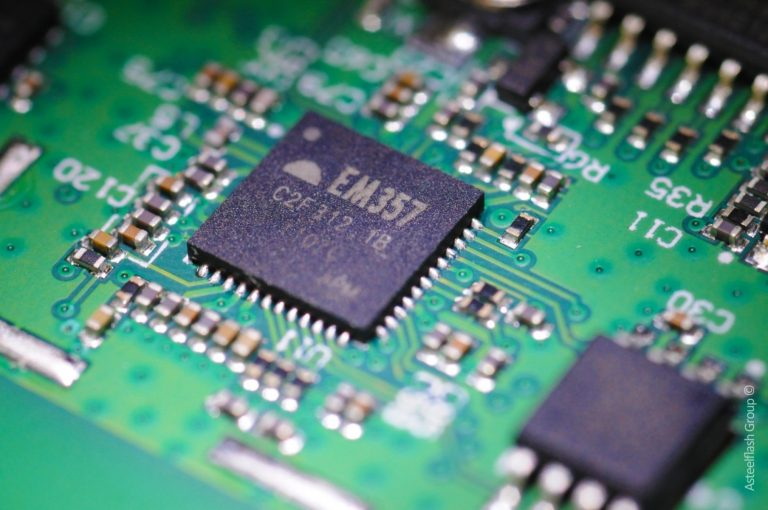

A double-sided PCB is a type of printed circuit board that allows components and copper traces to be placed on both the top and bottom surfaces. This design contrasts with single-sided PCBs, where components and wiring are confined to one side only. The double-sided approach significantly increases the available surface area for components and connections without increasing the board size.

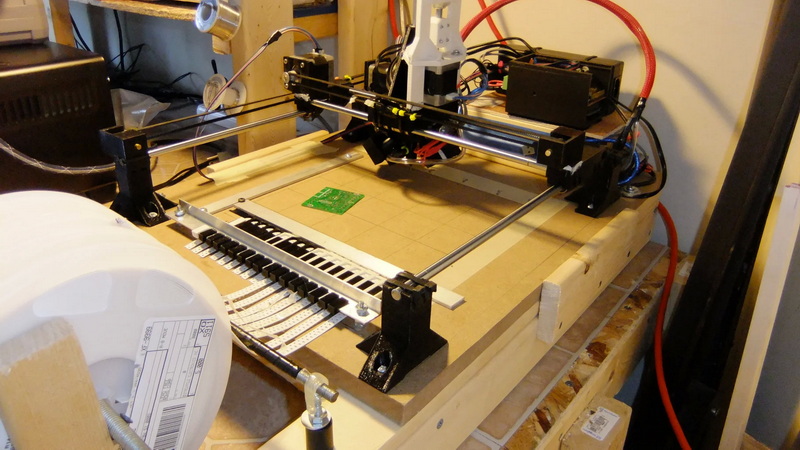

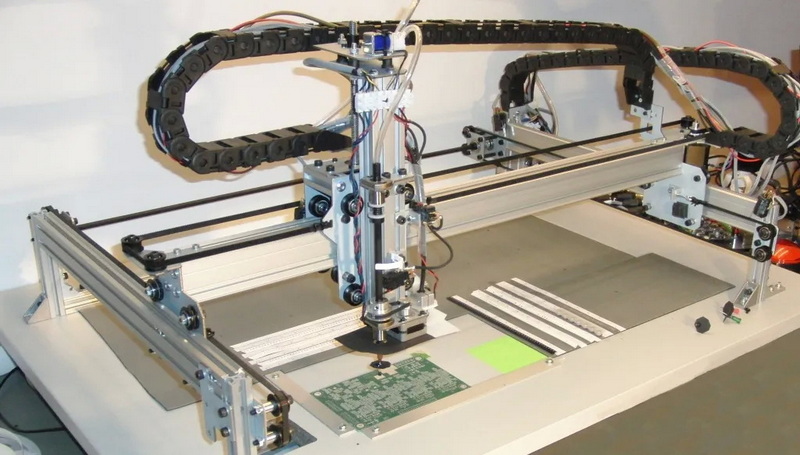

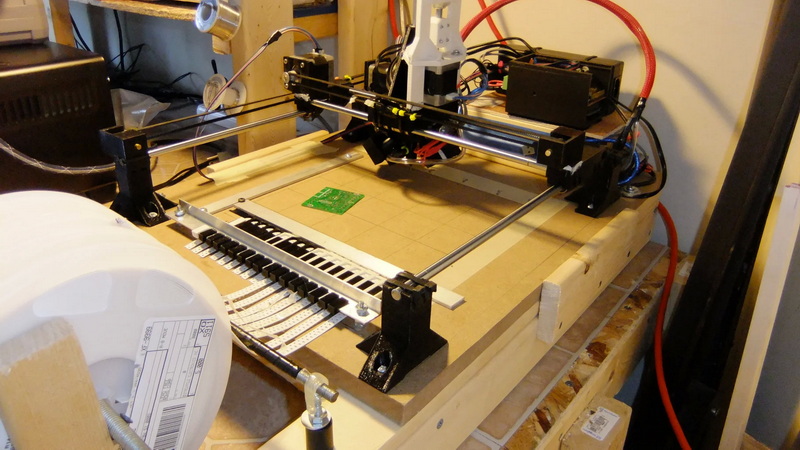

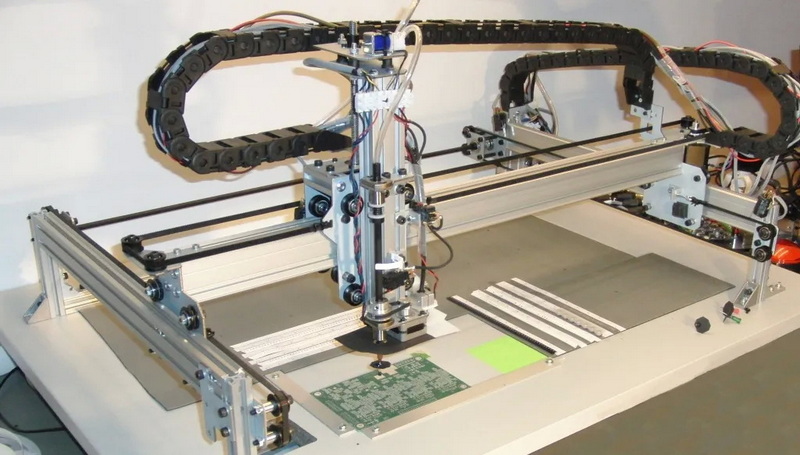

The assembly process for double-sided PCBs involves precise placement and soldering of components on both sides, often using surface mount technology (SMT) and through-hole techniques. This complexity requires advanced manufacturing capabilities and quality control to ensure reliability and performance.

Double-sided PCB assembly typically includes multiple stages such as solder paste application, component placement on one side, reflow soldering, flipping the board, and repeating the process on the other side. This intricate process demands sophisticated machinery and skilled operators to avoid defects such as solder bridging, misalignment, or component damage.

Key Advantages of Double-Sided PCB Assembly

Increased Circuit Density and Compact Design

One of the most significant benefits of double-sided PCB assembly is the ability to increase circuit density. By utilizing both sides of the board, designers can fit more components and intricate circuitry within the same footprint. This is crucial for modern electronics like smartphones, tablets, wearable devices, and compact medical instruments, where space is at a premium.

This higher component density enables manufacturers to develop smaller, lighter, and more powerful devices without compromising functionality. The design flexibility offered by double-sided PCBs facilitates the integration of complex features that single-sided boards cannot accommodate.

Moreover, double-sided PCBs allow for more efficient routing of electrical signals. By distributing components on both sides, designers can reduce the number of layers needed in a multilayer PCB, thereby lowering production costs and complexity while maintaining performance.

Enhanced Electrical Performance and Signal Integrity

Double-sided PCBs improve electrical performance by reducing the length of conductive paths between components. Shorter traces minimize signal loss, electromagnetic interference (EMI), and crosstalk, which are critical factors in high-frequency and high-speed electronic applications.

Moreover, the ability to separate ground planes and signal traces on different sides of the board helps maintain signal integrity. This separation reduces noise and interference, ensuring stable and reliable operation in telecommunications, automotive electronics, and aerospace systems.

The use of plated through-holes (vias) in double-sided PCBs further enhances connectivity between layers, enabling complex circuit designs that support advanced functionalities. This interconnection capability is vital for devices operating at high frequencies or requiring precise timing and synchronization.

Superior Thermal Management

Heat dissipation is a major concern in electronic device reliability and longevity. Double-sided PCBs offer enhanced thermal management capabilities due to the additional copper layer on the reverse side, which helps distribute and dissipate heat more effectively.

Improved thermal performance is particularly important in power electronics, LED lighting, and industrial equipment, where components generate significant heat. Efficient heat management prevents overheating, reduces failure rates, and extends the lifespan of electronic assemblies.

Thermal vias, which connect heat-generating components to the opposite copper layer, can be incorporated in double-sided PCBs to further improve heat transfer. This feature is essential for maintaining optimal operating temperatures in high-power applications.

Cost-Effectiveness and Production Efficiency

While double-sided PCBs may initially cost more than single-sided boards, they offer cost advantages in the long run. By placing components on both sides, manufacturers reduce the overall board size and material usage, leading to savings in raw materials and shipping.

Additionally, double-sided PCB assembly enables faster production times. Two-sided soldering operations can be performed simultaneously or in quick succession, accelerating the assembly process. This efficiency is vital for meeting tight deadlines and scaling production volumes, especially when sourcing wholesale PCB SMT assembly double sided services.

The economies of scale achieved through wholesale PCB SMT assembly double sided providers also contribute to cost savings. Bulk orders reduce per-unit costs, and experienced manufacturers optimize processes to minimize waste and rework.

Design Flexibility and Versatility

The dual-layer structure of double-sided PCBs provides engineers with greater design flexibility. Complex circuit layouts, multi-functional devices, and advanced features can be implemented more easily. Vias-small plated holes connecting the two sides-allow for intricate routing and interconnections that optimize board performance.

This versatility makes double-sided PCBs suitable for a wide range of applications, from consumer electronics to industrial automation, medical devices, automotive systems, and aerospace technology.

Additionally, double-sided PCBs support mixed technology assembly, where surface mount devices (SMDs) and through-hole components coexist. This capability is essential for integrating legacy components with modern SMT parts, enabling seamless upgrades and hybrid designs.

Applications of Double-Sided PCB Assembly

Double-sided PCB assembly is integral to numerous industries and applications, including:

- Consumer Electronics: Smartphones, tablets, laptops, and digital cameras rely on double-sided PCBs for compactness and functionality.

- Automotive Electronics: Engine control units, infotainment systems, and sensor modules benefit from the durability and performance of double-sided boards.

- Medical Devices: Diagnostic equipment and patient monitoring systems require reliable, high-density circuits that double-sided PCBs provide.

- Telecommunications: Routers, switches, and network devices utilize double-sided PCBs for efficient signal routing and high-speed data transmission.

- Industrial Equipment: Control systems and automation machinery depend on the enhanced reliability and thermal management of double-sided PCBs.

- LED Lighting: Double-sided PCBs enable efficient heat dissipation and reliable connections for LED arrays.

- Aerospace and Defense: Avionics and communication systems demand the robustness and high performance offered by double-sided PCB assemblies.

In addition, emerging technologies such as Internet of Things (IoT) devices, wearable health trackers, and smart home appliances increasingly rely on double-sided PCB assembly to meet their compact size and performance requirements.

The Role of Wholesale PCB SMT Assembly Double Sided Services

For manufacturers and businesses looking to produce modern electronic devices, partnering with wholesale PCB SMT assembly double sided providers is essential. These services offer:

- Cost Savings: Bulk purchasing and assembly reduce per-unit costs, making large-scale production economically viable.

- Quality Assurance: Experienced providers ensure precision in component placement, soldering, and testing, minimizing defects.

- Scalability: Wholesale services can handle varying production volumes, from prototypes to mass production.

- Technical Expertise: Providers assist with design optimization, material selection, and process improvements for double-sided PCBs.

- Faster Turnaround: Streamlined assembly processes and supply chain management accelerate project timelines.

Wholesale PCB SMT assembly double sided providers often invest in advanced equipment such as automated optical inspection (AOI), X-ray inspection, and in-circuit testing to guarantee product quality. Their expertise in handling complex double-sided assemblies helps reduce errors and improve yield rates.

Moreover, these providers can support just-in-time (JIT) manufacturing and flexible order sizes, enabling businesses to respond quickly to market changes and customer demands.

Future Trends in Double-Sided PCB Assembly

As electronic devices continue to evolve, double-sided PCB assembly will adapt to meet new challenges and opportunities. Some anticipated trends include:

- Integration with Flexible PCBs: Combining double-sided rigid PCBs with flexible circuits to create hybrid designs that offer both durability and adaptability.

- Advanced Materials: Use of high-performance substrates and lead-free solder materials to enhance thermal and electrical properties.

- Miniaturization: Further reduction in component sizes and pitch, requiring more precise assembly techniques for double-sided boards.

- Automation and AI: Increased use of artificial intelligence and machine learning in assembly lines to optimize processes and detect defects in real time.

- Sustainability: Adoption of eco-friendly manufacturing practices and recyclable materials in double-sided PCB production.

These trends will reinforce the importance of double-sided PCB assembly in delivering cutting-edge, reliable, and environmentally responsible electronic products.

Conclusion

Double-sided PCB assembly has become indispensable in the landscape of modern electronics. Its advantages in increasing circuit density, enhancing electrical performance, improving thermal management, and providing design flexibility make it the preferred choice for a wide array of applications. The ability to produce compact, high-functionality devices efficiently and cost-effectively is critical in today's competitive market.

Wholesale PCB SMT assembly double sided services further empower manufacturers by offering scalable, high-quality, and economical solutions that meet the demands of contemporary electronic design and production. As technology continues to advance, double-sided PCB assembly will remain a foundational element in delivering innovative and reliable electronic products.

FAQ

1. What is the main difference between single-sided and double-sided PCB assembly?

Single-sided PCBs have components and conductive traces on only one side of the board, limiting circuit complexity and component density. Double-sided PCBs feature conductive layers and component placement on both sides, allowing for higher circuit density, improved performance, and greater design flexibility.

2. Why is double-sided PCB assembly preferred for compact electronic devices?

Double-sided PCB assembly allows more components to be placed within the same board area by utilizing both sides, which is essential for compact devices like smartphones and wearables that require intricate circuitry without increasing size.

3. How does double-sided PCB assembly improve thermal management?

The additional copper layer on the reverse side of double-sided PCBs helps distribute and dissipate heat more effectively, preventing overheating and enhancing the reliability and lifespan of electronic components.

4. What role does wholesale PCB SMT assembly double sided play in manufacturing?

Wholesale PCB SMT assembly double sided services provide cost-effective, scalable, and high-quality assembly solutions, enabling manufacturers to produce complex double-sided PCBs efficiently and meet market demands with faster turnaround times.

5. Can double-sided PCBs be used in high-frequency applications?

Yes, double-sided PCBs improve signal integrity by reducing trace lengths and allowing separation of ground and signal layers, which minimizes electromagnetic interference and crosstalk, making them suitable for high-frequency and high-speed electronic applications.