Content Menu

● Understanding SMT Production Consumables

● Key Factors to Consider When Choosing Suppliers

>> 1. Quality of Products

>> 2. Supplier Reputation

>> 3. Technical Support and Service

>> 4. Pricing and Cost-Effectiveness

>> 5. Delivery and Lead Times

● Evaluating Potential Suppliers

>> 1. Request Samples

>> 2. Conduct Site Visits

>> 3. Compare Multiple Suppliers

>> 4. Negotiate Terms

● Building Long-Term Relationships

● Conclusion

● Frequently Asked Questions

>> 1. What are the most critical SMT production consumables?

>> 2. How can I ensure the quality of SMT consumables?

>> 3. What should I consider when negotiating with suppliers?

>> 4. How important is technical support from suppliers?

>> 5. How can I build a long-term relationship with my suppliers?

In the world of electronics manufacturing, Surface Mount Technology (SMT) has become a cornerstone for producing high-quality printed circuit boards (PCBs). A critical aspect of SMT production is the selection of consumables, which include solder paste, adhesives, and various components essential for the assembly process. Identifying the best suppliers for SMT production consumables is vital for ensuring efficiency, quality, and cost-effectiveness in manufacturing. This article will guide you through the process of selecting the right suppliers, focusing on key factors to consider, evaluation methods, and best practices.

Understanding SMT Production Consumables

Before diving into supplier selection, it's essential to understand what SMT production consumables are. These items are integral to the SMT process and include:

- Solder Paste: A mixture of solder powder and flux used to attach components to PCBs. The quality of solder paste can significantly affect the reliability of solder joints, making it crucial to choose a supplier that offers high-performance options.

- Adhesives: Used to secure components in place before soldering. Different types of adhesives are available, each suited for specific applications, such as high-temperature environments or moisture-sensitive components.

- Stencils: Templates used to apply solder paste accurately. The precision of stencils can influence the amount of solder applied, which is critical for achieving optimal solder joint quality.

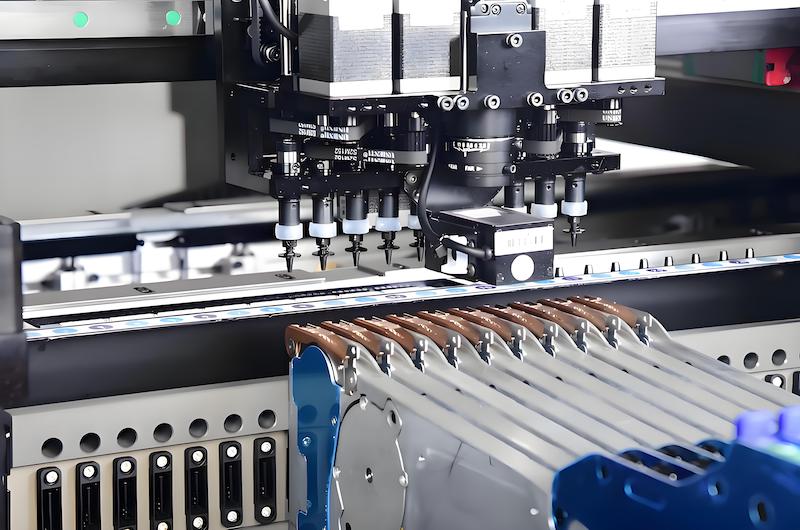

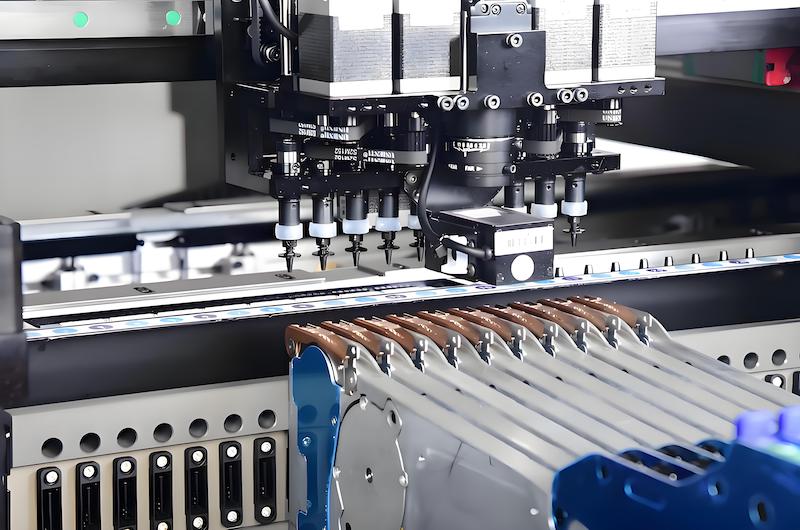

- Nozzles and Pick-and-Place Equipment: Tools that handle and place components on PCBs. The design and compatibility of nozzles with various components can impact the efficiency of the assembly process.

- Cleaning Agents: Solutions used to clean PCBs and equipment after production. The choice of cleaning agents can affect both the cleanliness of the boards and the longevity of the equipment.

Each of these consumables plays a crucial role in the overall quality and efficiency of the SMT process. Understanding their functions and the impact of their quality on production can help manufacturers make informed decisions when selecting suppliers.

Key Factors to Consider When Choosing Suppliers

1. Quality of Products

The quality of SMT production consumables directly impacts the reliability and performance of the final product. When evaluating suppliers, consider the following:

- Certifications: Look for suppliers that have industry-standard certifications such as ISO 9001 or IPC standards. These certifications indicate a commitment to quality management and product reliability, ensuring that the consumables meet stringent industry requirements.

- Material Specifications: Ensure that the consumables meet the required specifications for your production needs. This includes checking the composition of solder paste and the viscosity of adhesives. High-quality materials can lead to fewer defects and rework, ultimately saving time and costs.

2. Supplier Reputation

A supplier's reputation in the industry can provide insights into their reliability and product quality. Research potential suppliers by:

- Reading Reviews: Look for customer testimonials and reviews on industry forums and websites. Positive feedback from other manufacturers can be a strong indicator of a supplier's reliability and product performance.

- Asking for References: Request references from the supplier and contact previous clients to gauge their satisfaction with the products and services. This direct feedback can help you understand the supplier's strengths and weaknesses.

3. Technical Support and Service

Technical support is crucial, especially when dealing with complex SMT processes. Evaluate suppliers based on:

- Availability of Support: Ensure that the supplier offers timely technical support and assistance when needed. Quick access to support can minimize downtime and keep production running smoothly.

- Training Programs: Some suppliers provide training for their products, which can be beneficial for your team. Training can enhance your staff's understanding of the consumables and improve their ability to troubleshoot issues.

4. Pricing and Cost-Effectiveness

While quality is paramount, pricing also plays a significant role in supplier selection. Consider:

- Total Cost of Ownership: Look beyond the initial purchase price. Consider factors such as shipping costs, potential wastage, and the longevity of the consumables. A lower upfront cost may not always translate to savings if the consumables have a shorter lifespan or require more frequent replacement.

- Bulk Purchase Discounts: Inquire about discounts for bulk orders, which can significantly reduce costs. Establishing a long-term purchasing agreement can also lead to better pricing and terms.

5. Delivery and Lead Times

Timely delivery of SMT production consumables is essential to maintain production schedules. Assess suppliers based on:

- Lead Times: Understand the typical lead times for orders and ensure they align with your production schedule. Delays in receiving consumables can disrupt the entire manufacturing process.

- Inventory Management: Suppliers with robust inventory management systems can provide quicker turnaround times. A supplier that can anticipate demand and maintain adequate stock levels can be a valuable partner.

Evaluating Potential Suppliers

Once you have identified potential suppliers, it's time to evaluate them systematically. Here are some effective methods:

1. Request Samples

Before making a bulk purchase, request samples of the consumables. This allows you to test the products in your production environment and assess their performance. Testing samples can help identify any compatibility issues with your existing processes.

2. Conduct Site Visits

If possible, visit the supplier's facility. This can provide valuable insights into their manufacturing processes, quality control measures, and overall operations. Observing the production environment can help you assess the supplier's commitment to quality and innovation.

3. Compare Multiple Suppliers

Don't settle for the first supplier you find. Compare multiple suppliers based on the factors mentioned above. Create a scoring system to evaluate each supplier objectively. This systematic approach can help you make a more informed decision.

4. Negotiate Terms

Once you have narrowed down your options, negotiate terms that are favorable for your business. This includes pricing, payment terms, and delivery schedules. A well-negotiated agreement can lead to a mutually beneficial relationship.

Building Long-Term Relationships

After selecting a supplier, focus on building a long-term relationship. This can lead to better pricing, priority service, and improved collaboration. Here are some tips:

- Regular Communication: Maintain open lines of communication to address any issues promptly. Regular check-ins can help strengthen the partnership and ensure both parties are aligned.

- Feedback Loop: Provide feedback on product performance and service quality to help the supplier improve. Constructive feedback can foster innovation and enhance the quality of future products.

- Joint Development: Collaborate on new product development or improvements to existing consumables. Working together on innovations can lead to better solutions that meet your specific needs.

Conclusion

Identifying the best suppliers for SMT production consumables is a critical step in ensuring the success of your manufacturing operations. By focusing on quality, reputation, technical support, pricing, and delivery, you can make informed decisions that enhance your production efficiency and product quality. Remember, the right supplier can be a valuable partner in your manufacturing journey, contributing to your overall success in the competitive electronics market.

Frequently Asked Questions

1. What are the most critical SMT production consumables?

The most critical SMT production consumables include solder paste, adhesives, stencils, nozzles, and cleaning agents. Each of these items plays a vital role in the assembly process and affects the overall quality of the final product.

2. How can I ensure the quality of SMT consumables?

To ensure quality, look for suppliers with industry certifications, read customer reviews, and request product samples for testing. Conducting thorough evaluations can help you select high-quality consumables that meet your production standards.

3. What should I consider when negotiating with suppliers?

Consider pricing, payment terms, delivery schedules, and the possibility of bulk purchase discounts when negotiating with suppliers. A well-structured agreement can lead to a more favorable partnership.

4. How important is technical support from suppliers?

Technical support is crucial, especially for complex SMT processes. Reliable support can help resolve issues quickly and maintain production efficiency, minimizing downtime and disruptions.

5. How can I build a long-term relationship with my suppliers?

Maintain regular communication, provide feedback, and collaborate on product development to build a strong, long-term relationship with your suppliers. A solid partnership can lead to better service and innovative solutions tailored to your needs.