GSM08 Series SMT Single Splice Tape With Copper Clip Buckle

Brand Name :GS

Material: PET

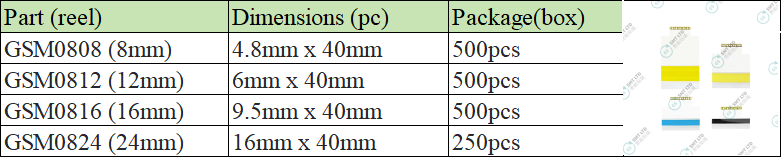

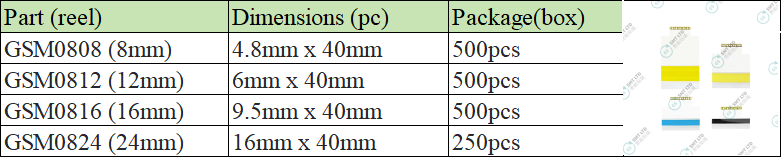

Model Number:

GSM0808 (8mm),GSM0812 (12mm)

GSM0816 (16mm),GSM0824 (24mm)

Product name:Single Splice Tapes

Application:SMT process

Customization:Support

Lead time:1-3 Days

一、Product Description

1.1 Innovative Design

The GSM08 Series Splice Tape with Clip features a labor-saving design that integrates strips of tape with a splice clip into a single piece. This design streamlines the splicing process, making it more efficient and user-friendly. The splice tape is made from high-quality PET, known for its excellent adhesion and durability, ensuring a reliable connection between carrier tapes.

1.2 Compatibility

This series is specifically designed to be compatible with Panasonic machines equipped with intelligent feeders. Additionally, it works seamlessly with various splice pliers, including the GSMTL00, GSMTL10, and GSMTL50, making it a versatile choice for different SMT setups.

1.3 Application

a. Single PET Tape Strips: Used to join SMT carrier tapes, the GSM08 splice tape provides a robust and durable connection.

b. Splice Tool and Clip: For enhanced connection strength, particularly on larger carrier tapes.

c. Tape Widths: Available in sizes ranging from 32mm to 88mm upon request, catering to various production needs.

d. OEM/EDM: Accepts Original Equipment Manufacturer (OEM) and Electronic Direct Mail (EDM) customization requests, offering flexibility to meet specific customer requirements.

二、Instructions for Use

2.1 Step-by-Step Application

a. Open the Splice Tool Jaws: Crimp the handle of the splice tool to open the front panel jaws. This action prepares the tool for the placement of the splice clip and carrier tapes.

b. Set Up the Splice Clip: Place a splice clip (teeth up) on the placement pins of the splice tool. The splice clip is a crucial component that ensures a secure and reliable connection between the carrier tapes.

c. Position the Carrier Tapes: Center both carrier tapes (cover tape up) on the placement pins of the splice tool. Secure the tapes in place using the clamps to ensure they do not move during the splicing process.

d. Crimp the Tapes: Crimp the handle of the splice tool to connect the carrier tapes. This action presses the splice clip into place, creating a strong and reliable bond between the tapes.

e. Apply the Splice Tape: Add a splice tape strip to the cover tape and press firmly to ensure it adheres well. This final step completes the splice, ensuring a secure and durable connection that will withstand the rigors of the SMT process.

2.2 Tips for Optimal Performance

- Clean Environment: Perform the splicing in a clean environment to prevent dust and other contaminants from affecting the adhesive.

- Proper Alignment: Ensure the carrier tapes are properly aligned during the splicing process to prevent feeding issues in the pick-and-place machine.

- Firm Pressure: Apply firm and even pressure when securing the splice to ensure maximum adhesion.

Hot tags:SMT Splicing Solutions,Copper Clip Splice Tape,Single Splice Tape,SMT Carrier Tape Splicing,Pick and Place Optimization,Splice Tape with Buckle,Efficient Tape Jointing,Feeder Reload Reduction,High-Strength Splice,SMT Adhesive Tape,china,wholesale, cheap, low price, manufacturers, factory, suppliers, for sale, in stock