Content Menu

● Understanding SMT Machine Feeders

>> Types of SMT Machine Feeders

>> The Importance of SMT Machine Feeders

● Choosing the Right SMT Machine Feeder

>> Innovations in SMT Feeder Technology

● Conclusion

>> Frequently Asked Questions (FAQs)

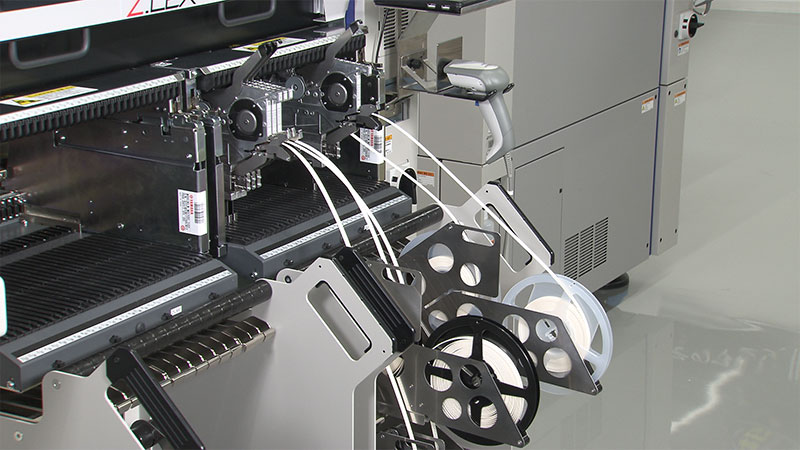

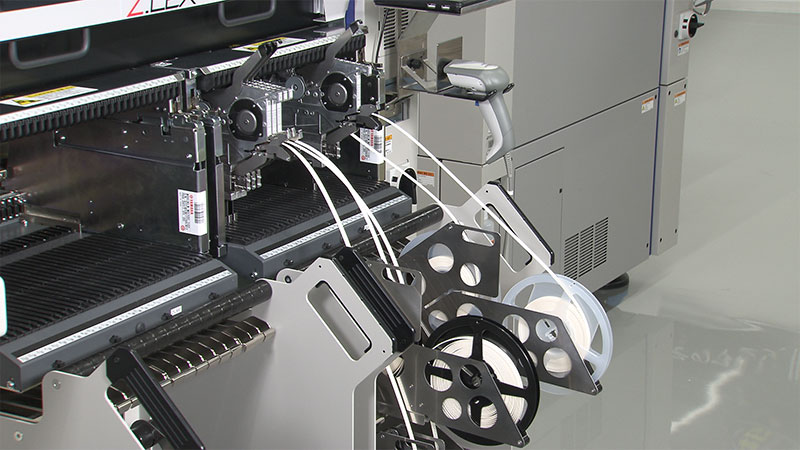

Understanding SMT Machine Feeders

What is an SMT Machine Feeder?

An SMT machine feeder is an automated device designed to supply surface-mounted components to a pick-and-place machine. These feeders hold components in various packaging formats, such as tape, trays, or tubes, and deliver them in a precise manner to ensure accurate placement on PCBs. The feeder operates by unwinding tape or advancing components from trays or tubes, allowing the pick-and-place machine to retrieve components efficiently.

Types of SMT Machine Feeders

There are several types of SMT machine feeders, each tailored for specific component types and packaging methods:

1. Tape Feeders

- Description: The most common type of feeder, tape feeders use reels of adhesive tape to hold components.

- Functionality: They unwind the tape and present each component to the pick-and-place nozzle.

- Advantages: High speed and accuracy, suitable for a wide range of components.

2. Tray Feeders

- Description: These feeders are designed for larger or irregularly shaped components housed in trays.

- Functionality: They can be single-layer or multi-layer, allowing for efficient use of space.

- Advantages: Ideal for integrated circuits (ICs) and other bulky components.

3. Stick Feeders

- Description: Used for components packaged in sticks, these feeders advance components using vibration or gravity.

- Functionality: They are suitable for non-polar rectangular and cylindrical components.

- Advantages: Flexibility in handling various component sizes.

4. Tube Feeders

- Description: Tube feeders guide long, delicate components from refillable tubes to the pick-up point.

- Functionality: Often used for LEDs or resistors.

- Advantages: Protects component pins during transport.

The Importance of SMT Machine Feeders

Efficiency and Speed

SMT machine feeders play a vital role in enhancing production efficiency. By ensuring a steady flow of components to the pick-and-place machines, they minimize downtime and maximize throughput. A well-functioning feeder can significantly reduce cycle times in PCB assembly.

Placement Accuracy

Accurate component placement is critical for the functionality of electronic devices. SMT machine feeders contribute to this accuracy by delivering components in the correct orientation and at precise intervals. This reduces misplacement errors that can lead to faulty circuits.

Reduced Waste

Efficient feeders minimize component damage during handling and transport. By reducing misfeeds and ensuring proper delivery, they help lower material waste and improve overall production costs.

Choosing the Right SMT Machine Feeder

Selecting the appropriate SMT machine feeder involves considering several factors:

- Component Size and Shape: The type of feeder must match the dimensions and packaging style of the components being used.

- Production Volume: High-speed feeders may be necessary for large production runs, while more versatile options might be better for smaller batches with varied component types.

- Feeder Compatibility: Ensure that the chosen feeder is compatible with your existing pick-and-place equipment.

Innovations in SMT Feeder Technology

Recent advancements in SMT feeder technology have led to features such as:

- Automatic Component Loading: Reduces manual intervention and speeds up setup times.

- Real-Time Monitoring: Provides data on component availability and feeder performance, allowing for proactive maintenance and adjustments.

Conclusion

SMT machine feeders are indispensable in modern electronics manufacturing. They streamline the assembly process by ensuring that components are delivered accurately and efficiently to pick-and-place machines. By understanding their types, functions, and importance, manufacturers can optimize their production lines for better efficiency and quality.

Frequently Asked Questions (FAQs)

1. What is an SMT machine feeder?

An SMT machine feeder is an automated device that supplies surface-mounted components to pick-and-place machines during PCB assembly.

2. What are the different types of SMT feeders?

The main types include tape feeders, tray feeders, stick feeders, and tube feeders, each suited for specific component packaging methods.

3. Why is placement accuracy important in SMT assembly?

Accurate placement ensures proper circuit functionality and minimizes errors that can lead to defective products.

4. How do I choose the right SMT feeder?

Consider factors such as component size, shape, production volume, and compatibility with existing equipment when selecting a feeder.

5. What innovations are being introduced in SMT feeder technology?

Innovations include automatic component loading systems and real-time monitoring capabilities to enhance efficiency and performance.