Content Menu

● Understanding SMT Feeders

>> Types of SMT Feeders

● Benefits of Customized SMT Feeders

>> 1. Enhanced Efficiency

>> 2. Improved Accuracy

>> 3. Flexibility in Production

>> 4. Cost-Effectiveness

>> 5. Enhanced Component Handling

>> 6. Integration with Advanced Technologies

>> 7. Tailored User Interfaces

● Choosing the Right SMT Feeder Manufacturer

● Conclusion

● Frequently Asked Questions

>> 1. What are SMT feeders used for?

>> 2. How do customized SMT feeders improve production efficiency?

>> 3. Can customized SMT feeders handle delicate components?

>> 4. What factors should I consider when choosing an SMT feeder manufacturer?

>> 5. Are customized SMT feeders more expensive than standard feeders?

In the fast-paced world of electronics manufacturing, the efficiency and accuracy of production processes are paramount. Surface Mount Technology (SMT) feeders play a crucial role in this landscape, serving as the backbone of automated assembly lines. Customized SMT feeders, in particular, offer a range of benefits that can significantly enhance production capabilities. This article explores the advantages of choosing customized SMT feeders, focusing on their impact on efficiency, flexibility, and overall production quality.

Understanding SMT Feeders

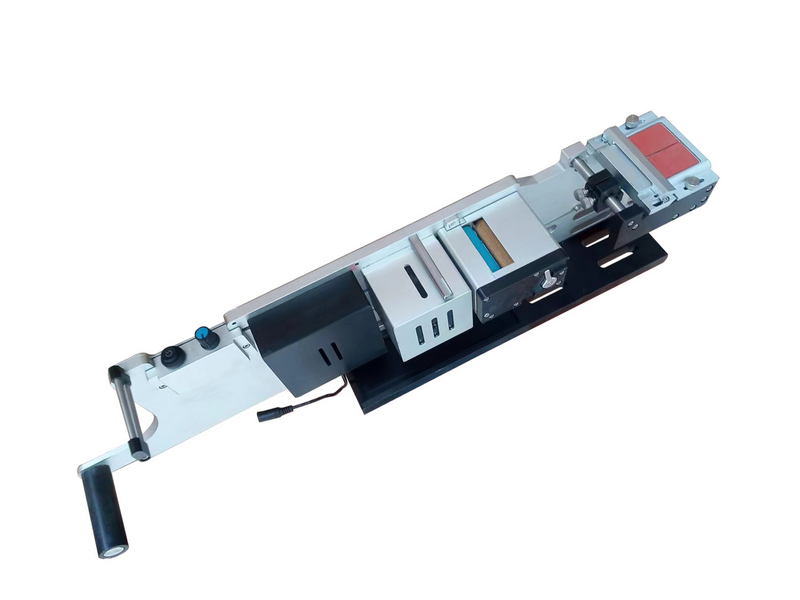

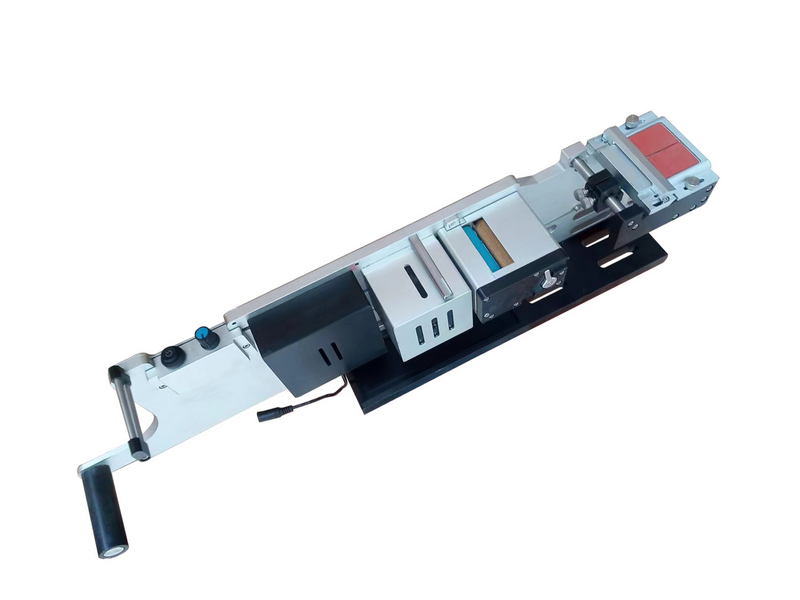

SMT feeders are devices used in automated assembly lines to supply components to pick-and-place machines. These feeders can handle various types of components, including resistors, capacitors, and integrated circuits, ensuring that the assembly process runs smoothly. The choice of feeder can greatly influence the speed and accuracy of the production line.

SMT feeders come in various designs and configurations, each tailored to meet specific production needs. For instance, some feeders are designed for high-speed operations, while others focus on precision handling of delicate components. Understanding the different types of feeders available is essential for manufacturers looking to optimize their production processes.

Types of SMT Feeders

1. Vibratory Feeders: These feeders use vibration to move components from a storage area to the pick-up point. They are ideal for bulk components and can handle a wide range of sizes. The vibratory mechanism ensures a continuous flow of parts, reducing the chances of jams and ensuring that the assembly line operates without interruptions.

2. Belt Feeders: Utilizing a conveyor belt mechanism, these feeders are suitable for larger components and can be customized to fit specific production needs. Belt feeders can be designed to accommodate various component sizes and shapes, making them versatile for different manufacturing scenarios.

3. Tube Feeders: Designed for smaller components, tube feeders ensure that parts are delivered in a controlled manner, minimizing the risk of damage. The enclosed design of tube feeders protects sensitive components from external factors, such as dust and moisture, which can affect their performance.

4. Custom Feeders: Tailored to meet specific production requirements, these feeders can be designed to handle unique components or configurations that standard feeders cannot accommodate. Custom feeders allow manufacturers to optimize their production lines for specific tasks, enhancing overall efficiency.

Benefits of Customized SMT Feeders

1. Enhanced Efficiency

One of the primary advantages of customized SMT feeders is their ability to enhance production efficiency. By tailoring feeders to specific components and production processes, manufacturers can reduce downtime and increase throughput. Customized feeders can handle multiple components simultaneously, allowing for faster assembly times and higher output.

This increased efficiency translates into shorter lead times and the ability to meet customer demands more effectively. In a competitive market, the ability to produce high-quality products quickly can be a significant advantage.

2. Improved Accuracy

Accuracy is critical in electronics manufacturing, where even minor errors can lead to significant issues. Customized SMT feeders can be designed to ensure precise placement of components, reducing the likelihood of misalignment or incorrect assembly. This precision is particularly important in high-density circuit boards, where space is limited, and component placement must be exact.

Moreover, the integration of advanced technologies, such as vision systems, can further enhance the accuracy of customized feeders. These systems can provide real-time feedback, allowing for immediate adjustments to ensure that components are placed correctly.

3. Flexibility in Production

The ability to adapt to changing production needs is another significant benefit of customized SMT feeders. As manufacturers introduce new products or modify existing ones, customized feeders can be adjusted or reconfigured to accommodate different components. This flexibility allows companies to respond quickly to market demands without the need for extensive downtime or retooling.

For instance, if a manufacturer decides to switch from producing one type of circuit board to another, a customized feeder can be reprogrammed or modified to handle the new components efficiently. This adaptability is crucial in today's fast-paced manufacturing environment.

4. Cost-Effectiveness

While the initial investment in customized SMT feeders may be higher than standard options, the long-term savings can be substantial. By increasing efficiency and reducing errors, customized feeders can lower overall production costs. Additionally, the ability to handle a wider variety of components can reduce the need for multiple feeder types, further streamlining operations.

Over time, the reduction in waste and the increase in production speed can lead to a significant return on investment. Manufacturers can allocate resources more effectively, focusing on quality and innovation rather than dealing with inefficiencies.

5. Enhanced Component Handling

Customized SMT feeders can be designed to handle specific types of components that may be challenging for standard feeders. For example, delicate components that require gentle handling can be accommodated with specialized feeder designs that minimize the risk of damage. This capability is essential for maintaining the integrity of sensitive electronic parts.

Furthermore, customized feeders can incorporate features such as soft landing mechanisms or adjustable speeds to ensure that components are handled with care throughout the assembly process. This attention to detail can significantly reduce the likelihood of defects and improve overall product quality.

6. Integration with Advanced Technologies

As manufacturing processes evolve, the integration of advanced technologies becomes increasingly important. Customized SMT feeders can be designed to work seamlessly with other automated systems, such as vision systems and smart monitoring tools. This integration enhances overall production efficiency and provides real-time data for better decision-making.

For example, a customized feeder equipped with sensors can monitor the flow of components and alert operators to any issues before they disrupt the production line. This proactive approach to maintenance can prevent costly downtime and ensure that production goals are met consistently.

7. Tailored User Interfaces

Modern SMT feeders often come equipped with user-friendly interfaces that simplify operation and maintenance. Customized feeders can include tailored controls that match the specific needs of the production team, making it easier to adjust settings and monitor performance metrics. This ease of use can lead to reduced training times and improved operator efficiency.

By providing operators with intuitive controls and clear feedback, manufacturers can enhance the overall user experience. This focus on usability can lead to higher employee satisfaction and lower turnover rates, further contributing to a more efficient production environment.

Choosing the Right SMT Feeder Manufacturer

When selecting a manufacturer for customized SMT feeders, several factors should be considered:

- Experience and Expertise: Look for manufacturers with a proven track record in producing high-quality SMT feeders. Their experience can provide valuable insights into the best solutions for your production needs. A manufacturer with a strong reputation in the industry is more likely to deliver reliable and effective products.

- Customization Capabilities: Ensure that the manufacturer can offer a range of customization options to meet your specific requirements. This includes the ability to design feeders for unique components and production environments. A flexible manufacturer can adapt to your changing needs over time.

- Support and Service: A reliable manufacturer should provide ongoing support and service, including maintenance and troubleshooting assistance. This support is crucial for minimizing downtime and ensuring smooth operations. Manufacturers that prioritize customer service can help you resolve issues quickly and efficiently.

- Quality Assurance: Choose a manufacturer that adheres to strict quality control standards. High-quality feeders are essential for maintaining production efficiency and accuracy. Look for certifications and industry standards that demonstrate a commitment to quality.

Conclusion

Customized SMT feeders offer numerous benefits that can significantly enhance production capabilities in electronics manufacturing. From improved efficiency and accuracy to greater flexibility and cost-effectiveness, these feeders are an essential investment for companies looking to optimize their assembly processes. By choosing the right SMT feeder manufacturer, businesses can ensure they have the tools necessary to meet the demands of a competitive market.

Frequently Asked Questions

1. What are SMT feeders used for?

SMT feeders are used in automated assembly lines to supply components to pick-and-place machines, ensuring efficient and accurate assembly of electronic devices.

2. How do customized SMT feeders improve production efficiency?

Customized SMT feeders are tailored to specific components and processes, allowing for faster assembly times and reduced downtime, which enhances overall production efficiency.

3. Can customized SMT feeders handle delicate components?

Yes, customized SMT feeders can be designed to handle delicate components with care, minimizing the risk of damage during the assembly process.

4. What factors should I consider when choosing an SMT feeder manufacturer?

Consider the manufacturer's experience, customization capabilities, support and service, and quality assurance standards when selecting an SMT feeder manufacturer.

5. Are customized SMT feeders more expensive than standard feeders?

While the initial investment may be higher, customized SMT feeders can lead to long-term savings through increased efficiency and reduced errors, making them a cost-effective choice.