Content Menu

>> Understanding SMT Splice Tools

>>> Key Features of SMT Splice Tools

>> The Role of Global Soul Limited as an SMT Splice Tool Supplier

>>> Products Offered by GS-SMT LTD

>> Advantages of Using SMT Splice Tools

>> Common Applications for SMT Splice Tools

>> Challenges Faced by Manufacturers

>> Future Trends in SMT Splicing Technology

>> Conclusion

>> Frequently Asked Questions (FAQs)

Understanding SMT Splice Tools

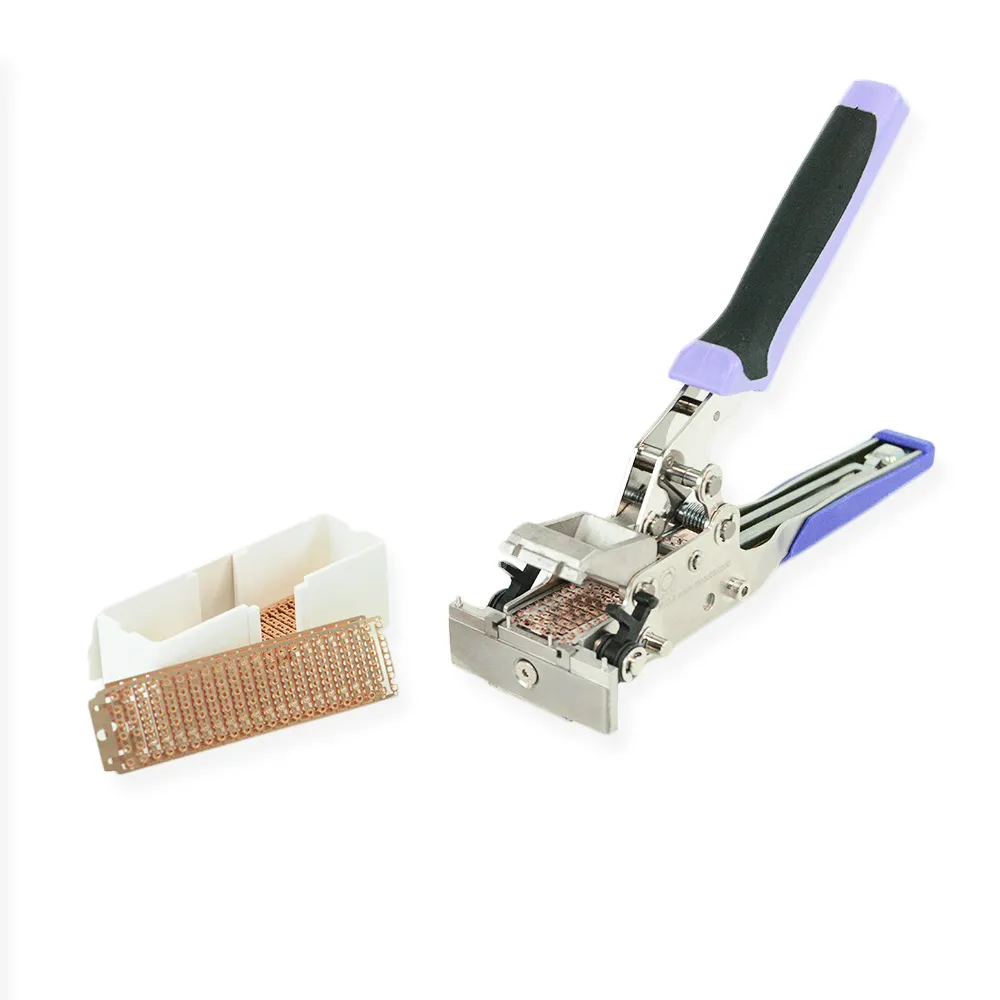

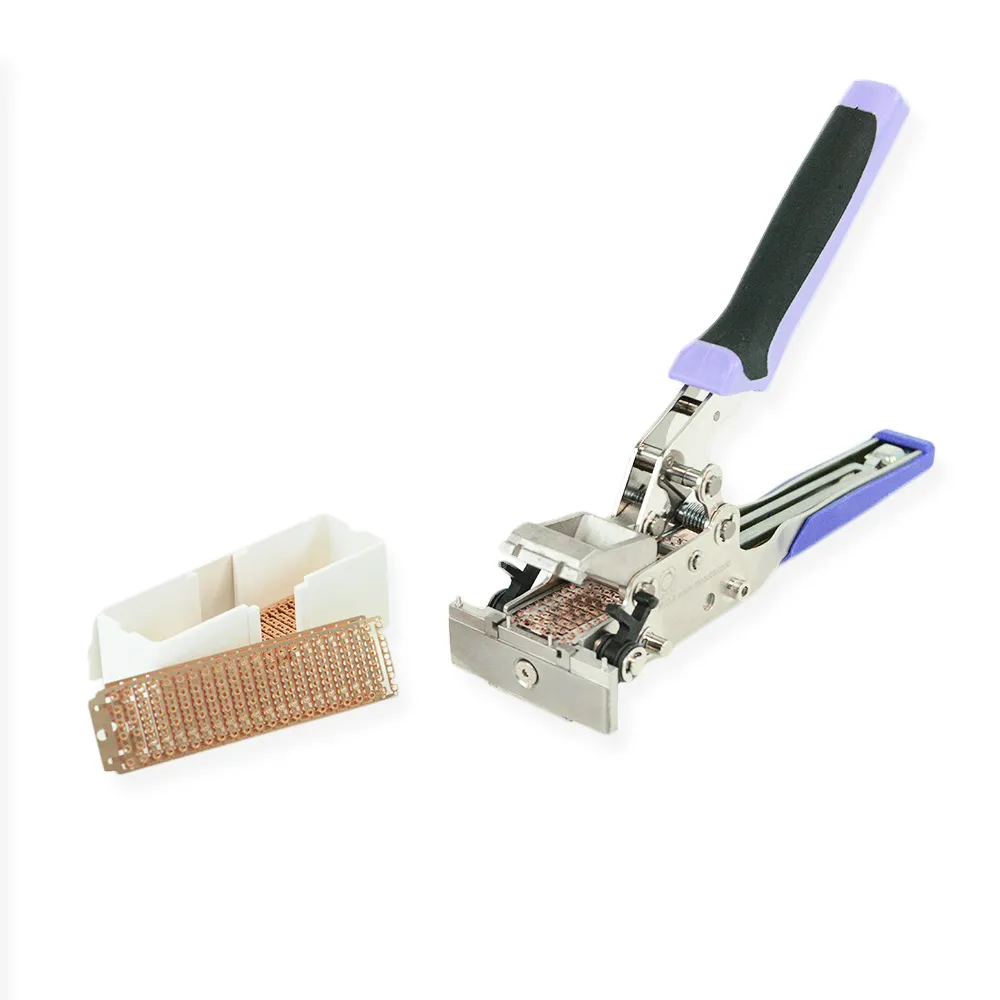

SMT splice tools are specialized instruments used to join two ends of carrier tape, allowing for a seamless transition from one reel of components to another. This process is crucial in maintaining continuous operation in pick and place machines, which are integral to SMT assembly lines.

Key Features of SMT Splice Tools

1. Durability: Most SMT splice tools are made from high-quality materials such as stainless steel, ensuring longevity and reliability.

2. Precision Alignment: Many tools include features like locating pins that guarantee accurate alignment when splicing tapes.

3. Ease of Use: Ergonomically designed handles make these tools comfortable to use, reducing operator fatigue during repetitive tasks.

4. Compatibility: They can be used with various types of carrier tapes, including both plastic and paper tapes.

The Role of Global Soul Limited as an SMT Splice Tool Supplier

Founded in 2011 and located in Shenzhen, China, Global Soul Limited (GS-SMT LTD) has established itself as a leading supplier of SMT solutions. As a prominent SMT splice tool supplier, GS-SMT LTD offers a range of products and services that cater to the needs of electronics manufacturers worldwide.

Products Offered by GS-SMT LTD

- Manual and Semi-Automatic SMT Splice Tools: Designed for ease and efficiency in splicing operations.

- Splice Tapes and Clips: Essential for creating strong bonds between tape ends.

- Technical Support and Training: Ensuring customers can maximize the use of their splicing tools.

Advantages of Using SMT Splice Tools

Utilizing SMT splice tools in production lines provides several benefits:

- Increased Efficiency: By allowing for quick changes between component reels, these tools minimize downtime.

- Cost Reduction: They enable manufacturers to utilize 100% of the components on a reel, reducing waste and costs associated with component loss.

- Enhanced Production Continuity: Seamless splicing helps maintain the flow of materials, essential for high-volume production environments.

Common Applications for SMT Splice Tools

SMT splice tools are widely used across various sectors within electronics manufacturing:

- Consumer Electronics: Used in assembling devices like smartphones and tablets.

- Automotive Industry: Essential for producing components such as sensors and control modules.

- Industrial Automation: Critical for manufacturing machinery and equipment.

Challenges Faced by Manufacturers

While SMT splice tools offer numerous advantages, manufacturers may face challenges when integrating them into their processes:

- Training Requirements: Operators must be trained to use these tools effectively to avoid errors during splicing.

- Initial Investment Costs: High-quality splice tools can represent a significant upfront investment.

- Maintenance Needs: Regular maintenance is necessary to ensure optimal performance.

Future Trends in SMT Splicing Technology

As technology continues to evolve, so too do the capabilities of SMT splice tools. Future trends may include:

- Automation Integration: Increasingly automated solutions that reduce manual handling during splicing.

- Smart Technology Features: Incorporating sensors and connectivity options for real-time monitoring and diagnostics.

- Sustainability Initiatives: Developing eco-friendly materials for splice tools to minimize environmental impact.

Conclusion

The importance of SMT splice tools in electronics manufacturing cannot be overstated. They enhance efficiency, reduce costs, and ensure smooth production processes. As a leading supplier, Global Soul Limited is committed to providing high-quality solutions tailored to meet the diverse needs of the industry.

Frequently Asked Questions (FAQs)

1. What is an SMT splice tool?

- An SMT splice tool is a device used to join two ends of carrier tape, facilitating seamless transitions between reels during production.

2. How does using an SMT splice tool improve efficiency?

- It reduces downtime by allowing quick changes between component reels, maintaining continuous operation in pick and place machines.

3. What materials are commonly used in SMT splice tools?

- Most splice tools are made from durable materials such as stainless steel or high-quality plastics.

4. Can SMT splice tools be used with different types of carrier tapes?

- Yes, they are compatible with both plastic and paper carrier tapes.

5. What support does Global Soul Limited provide for its products?

- GS-SMT offers technical support, training, and a range of splicing products to help manufacturers optimize their operations.