Content Menu

● Understanding SMT and Its Importance in PCB Production

>> Benefits of SMT in PCB Manufacturing

● Types of SMT Machines Essential for PCB Production

● Strategies for Finding Affordable SMT Machines

>> 1. Consider Refurbished or Used Equipment

>> 2. Explore Entry-Level or Desktop SMT Machines

>> 3. Look for Chinese Manufacturers

>> 4. Attend Trade Shows and Auctions

>> 5. Lease or Rent Equipment

● Factors to Consider When Choosing Affordable SMT Machines

● Case Studies: Successful Implementation of Affordable SMT Solutions

>> Small Electronics Startup

>> Medium-Sized Contract Manufacturer

● Tips for Maintaining and Optimizing Affordable SMT Machines

● The Future of Affordable SMT Technology

● Conclusion

● FAQ

>> 1. What is the most cost-effective SMT machine for a startup?

>> 2. How much does a basic SMT line for PCB production cost?

>> 3. Are Chinese SMT machines reliable for PCB production?

>> 4. How can I reduce the cost of SMT equipment without compromising quality?

>> 5. What are the key features to look for in affordable SMT machines for PCB production?

● Citations:

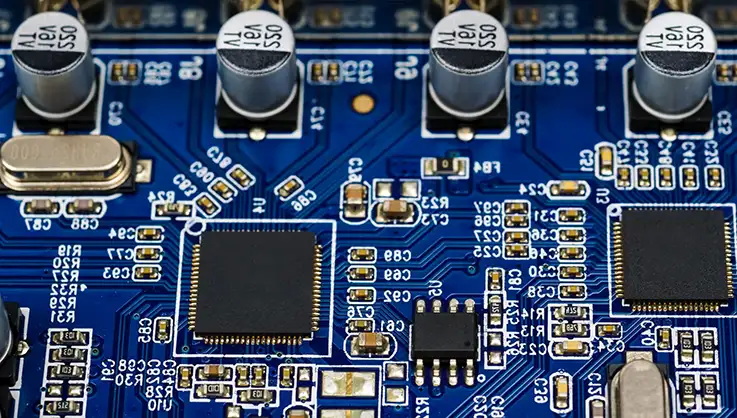

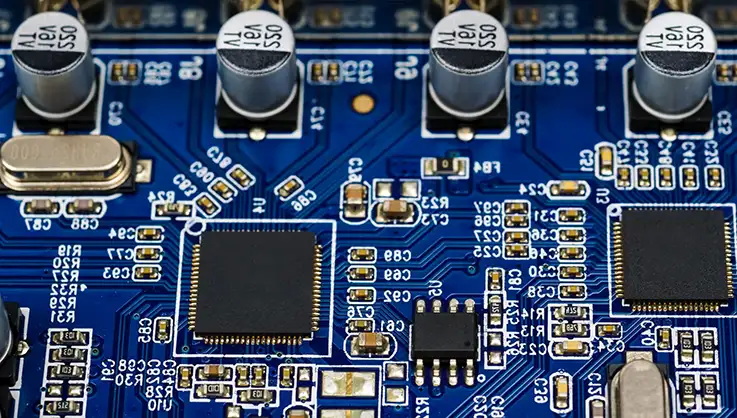

Surface Mount Technology (SMT) has revolutionized the electronics manufacturing industry, enabling the production of smaller, more complex, and more efficient printed circuit boards (PCBs). For many businesses, especially small to medium-sized enterprises and startups, finding affordable SMT machines for PCB production is crucial to remain competitive in the market. This article will explore various options and strategies for sourcing cost-effective SMT equipment without compromising on quality or productivity.

Understanding SMT and Its Importance in PCB Production

Surface Mount Technology is a method for producing electronic circuits in which the components are mounted or placed directly onto the surface of printed circuit boards. This technology has largely replaced the older through-hole technology, where component leads were inserted through holes in the PCB[1].

Benefits of SMT in PCB Manufacturing

1. Increased component density

2. Smaller and lighter PCBs

3. Improved electrical performance

4. Higher production speeds

5. Lower manufacturing costs at scale

Given these advantages, it's clear why SMT has become the standard in modern electronics manufacturing. However, the initial investment in SMT equipment can be substantial, making it challenging for smaller operations to enter the market or upgrade their existing facilities.

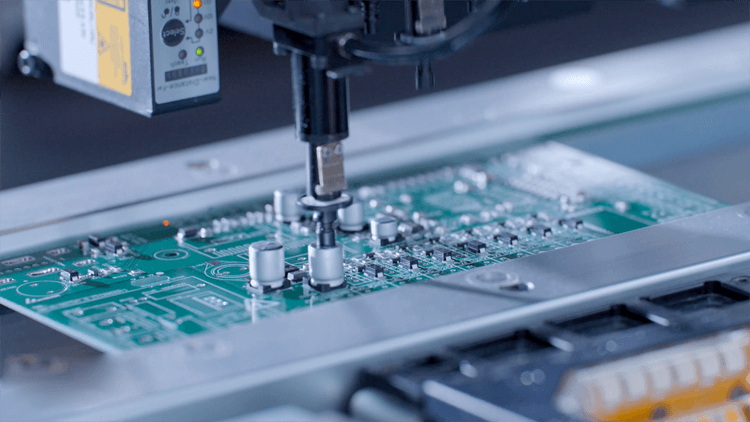

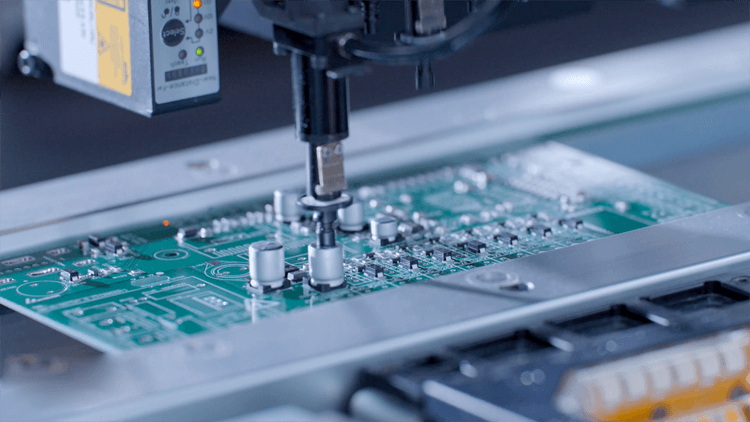

Types of SMT Machines Essential for PCB Production

Before delving into where to find affordable options, it's important to understand the key machines involved in the SMT process:

1. Solder Paste Printers

2. Pick and Place Machines

3. Reflow Ovens

4. Inspection Systems (AOI/AXI)

Among these, the pick and place machine is often the most expensive and crucial piece of equipment in the SMT line.

Strategies for Finding Affordable SMT Machines

1. Consider Refurbished or Used Equipment

One of the most effective ways to reduce costs is to look for refurbished or used SMT machines. Many reputable suppliers offer pre-owned equipment that has been thoroughly inspected, repaired, and restored to near-original condition[2].

Advantages:

- Significantly lower prices compared to new machines

- Often come with warranties

- Can be a good way to acquire high-end brands at a fraction of the cost

Considerations:

- Verify the machine's history and condition

- Check for availability of spare parts and support

- Ensure compatibility with your production requirements

2. Explore Entry-Level or Desktop SMT Machines

For businesses just starting or with lower production volumes, entry-level or desktop SMT machines can be an excellent option. These machines are designed to be more affordable and are often suitable for prototyping or small-scale production[3].

Popular Options:

- NeoDen4: A versatile pick and place machine suitable for small to medium production runs

- CharmHigh CHMT36VA: An affordable desktop pick and place machine with vision system

Advantages:

- Lower initial investment

- Smaller footprint, ideal for limited space

- Often easier to operate and maintain

Considerations:

- Lower placement speed compared to industrial machines

- May have limitations in component size and type

3. Look for Chinese Manufacturers

Chinese manufacturers have made significant strides in producing affordable SMT equipment that can compete with more established brands in terms of quality and performance[4].

Popular Chinese SMT Machine Manufacturers:

- Global Soul Limited

- Shenzhen JT Automation Equipment

- Zhejiang Torch Intelligent Equipment

Advantages:

- Significantly lower prices

- Improving quality and reliability

- Often offer good after-sales support

Considerations:

- Research thoroughly and read reviews from other users

- Check for CE certification and other relevant standards

- Consider potential language barriers in documentation and support

4. Attend Trade Shows and Auctions

Industry trade shows and auctions can be excellent sources for finding affordable SMT machines. Many manufacturers and suppliers offer special deals during these events, and you can often find used equipment at auction[5].

Advantages:

- Opportunity to see machines in person and compare different options

- Potential for significant discounts or package deals

- Networking opportunities with industry professionals

Considerations:

- Travel costs may offset savings for distant events

- Be prepared to make quick decisions at auctions

5. Lease or Rent Equipment

For businesses not ready to commit to a large capital investment, leasing or renting SMT equipment can be a viable option.

Advantages:

- Lower upfront costs

- Flexibility to upgrade as your business grows

- Often includes maintenance and support

Considerations:

- May be more expensive in the long term

- Less control over equipment specifications

Factors to Consider When Choosing Affordable SMT Machines

While cost is a significant factor, it shouldn't be the only consideration when selecting SMT equipment for your PCB production:

1. Production Volume: Ensure the machine's capacity matches your current and projected production needs.

2. Component Range: Verify that the machine can handle the types and sizes of components you use.

3. Accuracy and Speed: Even affordable machines should meet your quality and production rate requirements.

4. Software and Integration: Consider the ease of programming and integration with your existing systems.

5. Support and Maintenance: Check the availability of spare parts, technical support, and maintenance services.

6. Upgradability: Look for machines that can be upgraded or expanded as your needs grow.

7. Total Cost of Ownership: Factor in ongoing costs such as energy consumption, maintenance, and consumables.

Case Studies: Successful Implementation of Affordable SMT Solutions

Small Electronics Startup

A startup specializing in IoT devices managed to set up a complete SMT line for under $50,000 by:

- Purchasing a refurbished Yamaha YS12 pick and place machine

- Opting for a new but entry-level reflow oven

- Using a manual stencil printer initially, with plans to upgrade later

This setup allowed them to produce 500-1000 PCBs per day, meeting their initial production needs while keeping costs low.

Medium-Sized Contract Manufacturer

A contract manufacturer expanded their capacity by:

- Acquiring two used Juki pick and place machines at an industry auction

- Investing in a new, high-speed solder paste printer to improve overall line efficiency

- Utilizing their existing reflow oven

This strategic mix of new and used equipment allowed them to double their production capacity while staying within budget.

Tips for Maintaining and Optimizing Affordable SMT Machines

1. Regular Maintenance: Implement a strict maintenance schedule to prevent breakdowns and extend machine life.

2. Operator Training: Invest in thorough training for your staff to ensure proper machine operation and reduce errors.

3. Optimize Programming: Regularly review and optimize your pick and place programs to improve efficiency.

4. Quality Control: Implement robust quality control measures to catch and correct issues early.

5. Upgrade Strategically: Plan for strategic upgrades of individual components or modules as your budget allows.

The Future of Affordable SMT Technology

As technology advances, we can expect to see continued improvements in the affordability and capabilities of SMT equipment:

- Increased Automation: More affordable machines with advanced features like automatic component teaching and self-correction.

- AI Integration: Artificial intelligence may help optimize placement strategies and predict maintenance needs.

- Modular Systems: Expect more modular SMT solutions that allow for easier upgrades and customization.

- Improved Energy Efficiency: Future machines may offer significant energy savings, reducing long-term operational costs.

Conclusion

Finding affordable SMT machines for PCB production is entirely possible with the right approach and knowledge. By considering options such as refurbished equipment, entry-level machines, or products from emerging manufacturers, businesses can establish or upgrade their SMT capabilities without breaking the bank. Remember to balance cost considerations with your specific production needs, quality requirements, and long-term growth plans. With careful research and strategic decision-making, you can find SMT solutions that offer the best value for your investment and set your PCB production up for success.

FAQ

1. What is the most cost-effective SMT machine for a startup?

For startups, the most cost-effective SMT machine is often a desktop pick and place machine like the NeoDen4 or CharmHigh CHMT36VA. These machines offer a good balance of affordability, flexibility, and performance for low to medium volume production. They're particularly suitable for prototyping and small batch runs, allowing startups to bring production in-house without a massive initial investment.

2. How much does a basic SMT line for PCB production cost?

The cost of a basic SMT line can vary widely, but you can set up a functional line for as little as $30,000 to $100,000, depending on your choices. This would typically include:

- A manual or semi-automatic stencil printer ($2,000 - $10,000)

- An entry-level pick and place machine ($10,000 - $50,000)

- A small reflow oven ($5,000 - $20,000)

- Basic inspection equipment ($2,000 - $10,000)

Remember, these are rough estimates and costs can be higher or lower based on specific equipment choices and whether you opt for new or used machines.

3. Are Chinese SMT machines reliable for PCB production?

Chinese SMT machines have significantly improved in reliability and performance over the past decade. Many Chinese manufacturers now produce machines that offer good value for money, especially for small to medium-sized operations. However, it's crucial to do thorough research, read reviews, and if possible, see the machines in operation before purchasing. Look for CE certification and other relevant standards to ensure quality. While they may not match the top-tier brands in all aspects, many Chinese SMT machines are more than capable of handling standard PCB production tasks reliably.

4. How can I reduce the cost of SMT equipment without compromising quality?

To reduce costs without compromising quality, consider these strategies:

1. Look for refurbished equipment from reputable dealers

2. Consider leasing options for high-end machines

3. Start with essential equipment and upgrade gradually

4. Opt for modular systems that allow for future expansion

5. Invest in good maintenance to extend equipment life

6. Explore entry-level machines from established brands

7. Attend trade shows and auctions for potential deals

By carefully balancing these options, you can build a capable SMT line while managing costs effectively.

5. What are the key features to look for in affordable SMT machines for PCB production?

When searching for affordable SMT machines for PCB production, prioritize these key features:

1. Adequate placement speed and accuracy for your needs

2. Compatibility with your component range (size and type)

3. User-friendly software and programming interface

4. Reliable vision system for component recognition

5. Flexibility to handle different PCB sizes

6. Good customer support and availability of spare parts

7. Energy efficiency to reduce long-term operational costs

8. Upgradability or expandability options

Remember, "affordable" doesn't mean sacrificing essential features – it means finding the best value for your specific production requirements.

Citations:

[1] https://www.pcbelec.com/pcb-assembly/smt-pcb-assembly

[2] https://www.smtneoden.com/news/how-much-does-a-pick-and-place-machine-cost/

[3] https://www.alibaba.com/showroom/smt-pick-place-machine-price.html

[4] https://www.smtfactory.com/products/pcb-smt-machine.html

[5] https://www.raypcb.com/smt-machine/

[6] https://neodenusa.com/smt-pick-and-place-machines/

[7] https://www.alibaba.com/showroom/the-price-of-smt-machine.html

[8] https://chipbest.en.made-in-china.com/product/OQvrZjdVdyWw/China-High-Precision-SMT-PCB-Board-Printing-Machine-SMT-PCB-Solder-Paste-Printing-Machine-Small-PCB-Making-Machine.html

[9] https://www.made-in-china.com/products-search/hot-china-products/SMT_Machine.html

[10] https://www.pcbonline.com/blog/smt-manufacturing-process.html