Content Menu

● Introduction to SMD Soldering Machines

>> OEM SMD Soldering Machines for LED Lighting

● Safety Precautions for Operating SMD Soldering Machines

>> 1. Personal Protective Equipment (PPE):

>> 2. Work Environment:

>> 3. Machine Maintenance:

>> 4. Training and Operation:

>> 5. Electrical Safety:

● Advanced Safety Features in OEM SMD Soldering Machines

● Importance of OEM SMD Soldering Machines in LED Lighting Production

● Challenges and Solutions in Implementing Safety Measures

● Future Developments in SMD Soldering Technology

● Conclusion

● FAQ

>> 1. What are the essential safety precautions when operating SMD soldering machines?

>> 2. How do OEM SMD soldering machines benefit LED lighting production?

>> 3. What are some advanced safety features in modern OEM SMD soldering machines?

>> 4. Why is proper ventilation important when operating SMD soldering machines?

>> 5. How often should SMD soldering machines be maintained?

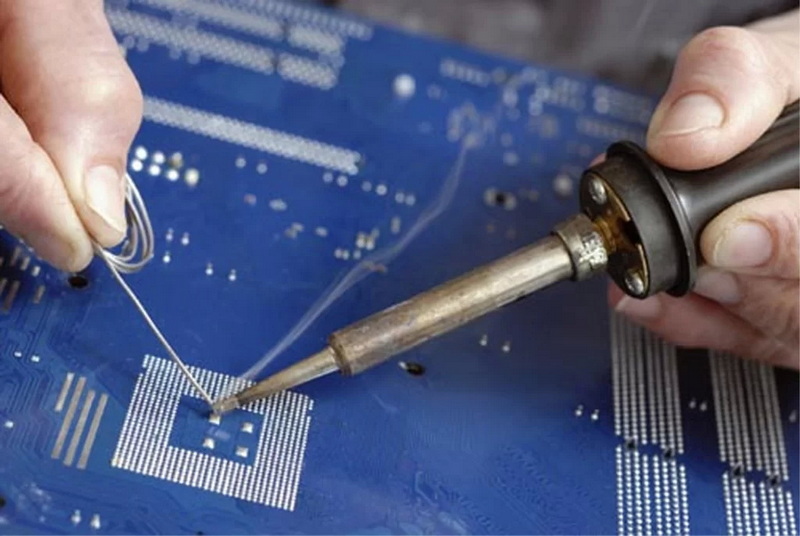

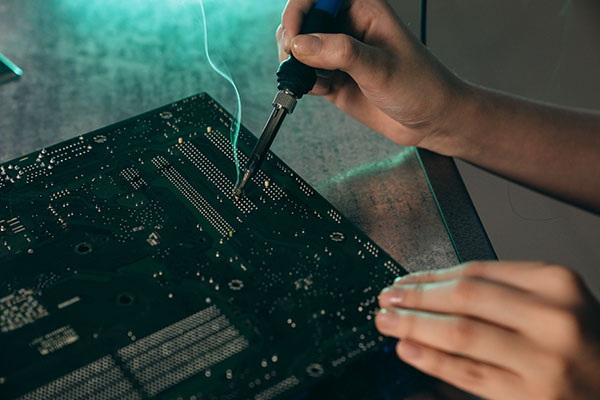

SMD (Surface Mount Device) soldering machines are crucial in the production of electronic components, including LED lighting. These machines provide efficient and precise soldering processes, ensuring high-quality connections in electronic circuits. However, operating SMD soldering machines requires adherence to strict safety guidelines to prevent accidents and ensure a safe working environment. This article will delve into the essential safety precautions for operating SMD soldering machines, particularly focusing on OEM SMD soldering machines for LED lighting.

Introduction to SMD Soldering Machines

SMD soldering machines are designed to automate the soldering process for surface mount components. They are widely used in the electronics industry, including the production of LED lighting products. These machines offer advanced features such as temperature control, adjustable soldering speed, and user-friendly interfaces, making them efficient for both small-scale and large-scale manufacturing.

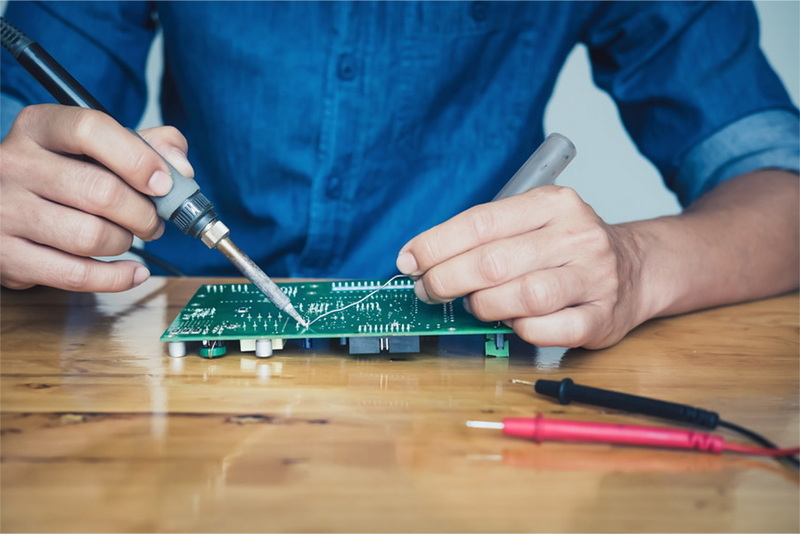

OEM SMD Soldering Machines for LED Lighting

OEM (Original Equipment Manufacturer) SMD soldering machines are specifically designed for LED lighting manufacturers. These machines are tailored to meet the precise soldering requirements of LED components, ensuring consistent and durable connections. OEM machines are often customized to fit the specific needs of the manufacturer, providing optimal performance and reliability in the production line. For instance, some OEM machines may include specialized nozzles or soldering tips designed specifically for LED components, enhancing the quality of the solder joints.

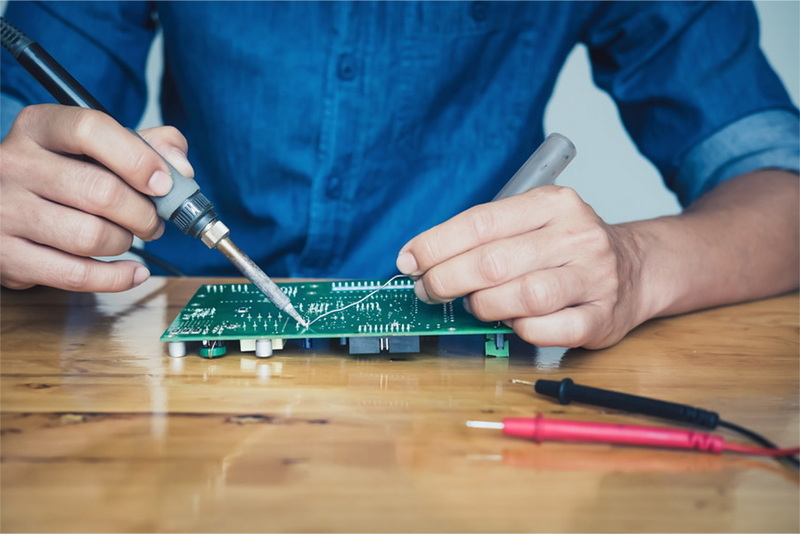

Safety Precautions for Operating SMD Soldering Machines

Operating SMD soldering machines involves several safety risks, including electrical hazards, thermal burns, and exposure to harmful fumes. To mitigate these risks, the following safety precautions should be taken:

1. Personal Protective Equipment (PPE):

- Safety Goggles: Protect eyes from solder splashes and debris.

- Gloves: Prevent burns and electrical shocks.

- Safety Shoes: Protect feet from heavy objects and electrical hazards.

- Face Masks: Prevent inhalation of solder fumes and particles.

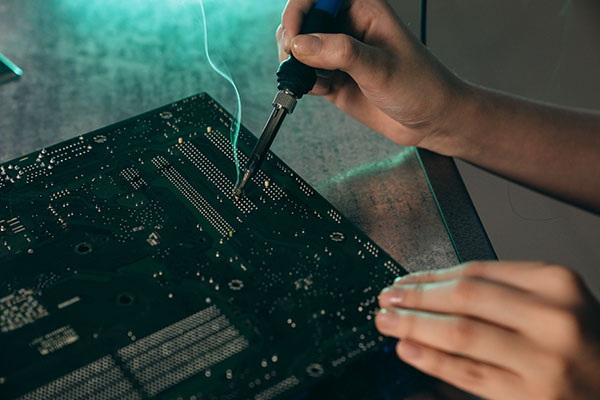

2. Work Environment:

- Ensure good ventilation to prevent inhalation of solder fumes.

- Use a fume extractor to remove harmful particles from the air.

- Keep the workspace clean and organized to prevent tripping hazards.

- Maintain a safe distance from flammable materials.

3. Machine Maintenance:

- Regularly inspect and maintain the machine to prevent mechanical failures.

- Follow the manufacturer's instructions for maintenance and repair.

- Ensure all electrical components are properly grounded.

- Keep a record of maintenance activities for future reference.

4. Training and Operation:

- Provide comprehensive training to operators on machine operation, safety procedures, and troubleshooting.

- Ensure operators understand the machine's features and limitations.

- Operate the machine according to the manufacturer's guidelines.

- Encourage operators to report any anomalies or issues promptly.

5. Electrical Safety:

- Use grounded outlets and ensure all electrical cords are in good condition.

- Avoid soldering live circuits.

- Keep electrical components away from heat sources.

- Use surge protectors to prevent electrical surges.

Advanced Safety Features in OEM SMD Soldering Machines

Modern OEM SMD soldering machines for LED lighting often come equipped with advanced safety features:

- Temperature Control: Allows precise control over soldering temperatures, reducing the risk of overheating components.

- Automated Soldering Process: Minimizes human error and exposure to hot solder.

- Safety Sensors: Detect anomalies in the soldering process and automatically shut down the machine if necessary.

- Emergency Stop Buttons: Quickly halt the machine in case of emergencies.

- Visual and Auditory Alarms: Alert operators to potential hazards or machine malfunctions.

Importance of OEM SMD Soldering Machines in LED Lighting Production

OEM SMD soldering machines play a vital role in the production of LED lighting products by ensuring:

- Consistency: Provides uniform soldering quality across all components.

- Efficiency: Automates the soldering process, increasing production speed and reducing labor costs.

- Reliability: Ensures durable connections, enhancing the lifespan of LED lighting products.

- Customization: Allows manufacturers to tailor the soldering process to specific LED components, optimizing performance.

Challenges and Solutions in Implementing Safety Measures

Implementing safety measures in SMD soldering operations can present several challenges, including cost, training time, and maintaining production efficiency. However, these challenges can be addressed by:

- Investing in Quality Equipment: While initial costs may be higher, quality OEM machines provide long-term benefits in safety and efficiency.

- Comprehensive Training Programs: Regular training sessions ensure that operators are well-versed in safety procedures and machine operation.

- Continuous Monitoring: Regularly review and update safety protocols to adapt to new technologies and operational changes.

Future Developments in SMD Soldering Technology

As technology advances, SMD soldering machines are expected to incorporate even more sophisticated safety features and automation capabilities. Future developments may include:

- Artificial Intelligence (AI) Integration: AI can enhance predictive maintenance, detect potential safety hazards, and optimize soldering processes.

- Robotics: Increased use of robotics can further reduce human exposure to soldering hazards.

- Green Technology: Machines may be designed to reduce energy consumption and minimize environmental impact.

Conclusion

Operating SMD soldering machines, especially OEM machines designed for LED lighting, requires strict adherence to safety guidelines. By understanding and implementing these precautions, manufacturers can ensure a safe working environment while maintaining high production standards. The use of advanced safety features in modern OEM machines further enhances operational safety and efficiency. As technology continues to evolve, it is crucial for manufacturers to stay updated with the latest developments in SMD soldering technology to maintain a competitive edge in the industry.

FAQ

1. What are the essential safety precautions when operating SMD soldering machines?

Answer: Essential safety precautions include wearing personal protective equipment (PPE), maintaining a safe work environment, ensuring proper machine maintenance, providing operator training, and adhering to electrical safety guidelines.

2. How do OEM SMD soldering machines benefit LED lighting production?

Answer: OEM SMD soldering machines benefit LED lighting production by providing consistent and efficient soldering processes, ensuring durable connections, and enhancing production speed.

3. What are some advanced safety features in modern OEM SMD soldering machines?

Answer: Advanced safety features include precise temperature control, automated soldering processes, safety sensors, emergency stop buttons, and visual and auditory alarms.

4. Why is proper ventilation important when operating SMD soldering machines?

Answer: Proper ventilation is crucial to prevent the inhalation of harmful solder fumes and particles, which can cause respiratory issues and other health problems.

5. How often should SMD soldering machines be maintained?

Answer: SMD soldering machines should be regularly inspected and maintained according to the manufacturer's schedule to prevent mechanical failures and ensure optimal performance.