Content Menu

● Introduction to SMT Component Reel Counters

>> Role of Automation

● Innovations in SMT Component Reel Counters

● Applications Across Industries

● Challenges and Future Directions

>> Real-World Applications and Success Stories

● Integration with Industry 4.0

>> DIY and Custom Solutions

>> Future Trends

● Conclusion

● FAQs

>> 1. What is an SMT component reel counter?

>> 2. How does an X-ray SMT reel counter work?

>> 3. What are the benefits of using an SMT reel counter?

>> 4. How does AI integration improve SMT reel counters?

>> 5. What industries use SMT component reel counters?

The future of SMT (Surface Mount Technology) component reel counters is being shaped by several innovative technologies and methodologies. These advancements are crucial for enhancing efficiency, accuracy, and cost-effectiveness in the electronics manufacturing industry. In this article, we will explore the key innovations transforming the landscape of SMT component reel counters.

Introduction to SMT Component Reel Counters

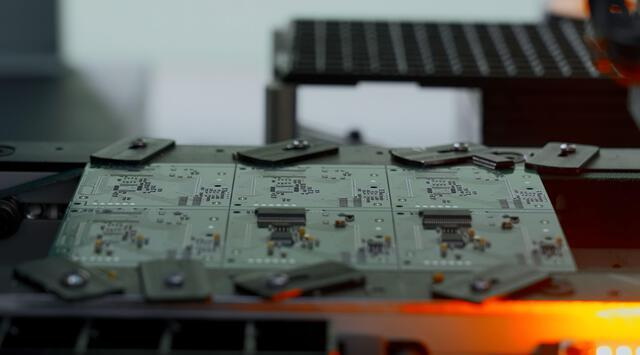

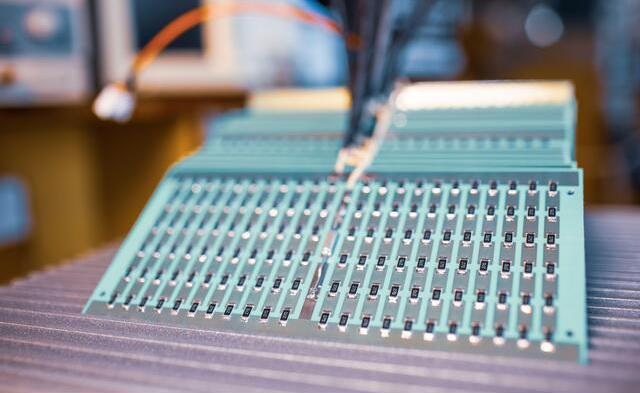

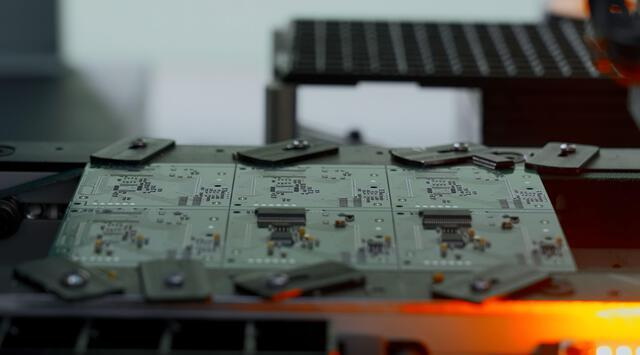

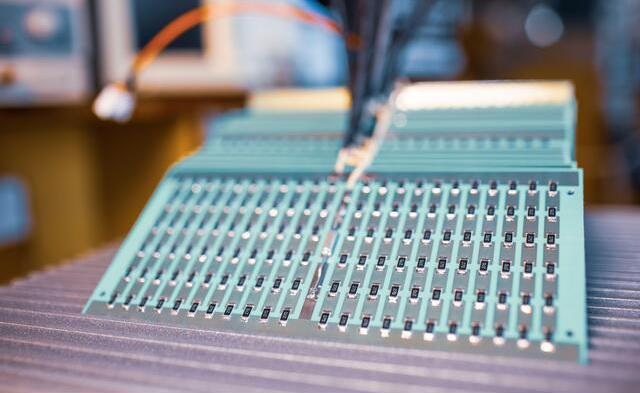

SMT component reel counters are specialized devices used in the electronics manufacturing sector to accurately count the number of components on a reel. These components, such as resistors, capacitors, and integrated circuits, are essential for the production of electronic circuits. Traditional manual counting methods are time-consuming and prone to errors, which can lead to production delays and increased costs. Therefore, automated SMT component reel counters have become indispensable tools for modern manufacturing processes.

Role of Automation

Automation is a cornerstone of modern manufacturing, and SMT component reel counters embody this principle. By leveraging advanced technologies like optical recognition, machine vision, and X-ray imaging, these counters can accurately and rapidly count components without manual intervention. This automation not only reduces labor costs but also minimizes the risk of human error, ensuring that production lines operate smoothly and efficiently.

Innovations in SMT Component Reel Counters

Several innovations are driving the evolution of SMT component reel counters:

1. X-ray Technology: X-ray counters use X-ray imaging to non-destructively analyze the contents of a reel, providing precise counts without damaging the components. This technology is particularly valuable in high-volume production environments where accuracy and speed are paramount. X-ray counters can also inspect the internal structure of components, detecting defects such as soldering issues, which enhances quality control.

2. Machine Learning and AI Integration: The integration of Artificial Intelligence (AI) and Machine Learning (ML) is transforming the capabilities of SMT reel counters. These technologies enable real-time data analysis, improving the accuracy of defect detection and reducing false positives. AI-driven systems can learn from historical data, adapting their detection criteria based on patterns and anomalies, which significantly enhances the reliability of inspections in manufacturing processes.

3. Industry 4.0 and IoT Connectivity: The adoption of Industry 4.0 principles, such as IoT connectivity, will enable real-time monitoring and remote diagnostics of SMT reel counters. This connectivity enhances operational efficiency by reducing downtime and allowing for predictive maintenance.

4. Advanced Sensors and Algorithms: Modern SMT reel counters utilize advanced sensors and sophisticated algorithms to ensure precise and reliable counting. These technologies reduce the risk of miscounted or missing components during production, contributing to high-quality standards in manufacturing.

5. Integration with Management Systems: SMT reel counters can seamlessly integrate with ERP, MES, and WMS systems, allowing for real-time updates of inventory levels and enhancing supply chain management. This integration is crucial for maintaining accurate stock levels and optimizing production planning.

Applications Across Industries

SMT component reel counters are not limited to the electronics manufacturing sector; they are also critical in other industries where precision and reliability are paramount:

- Electronics Manufacturing: SMT reel counters are essential for SMT production lines where component accuracy is vital. They ensure that the correct number of components are used, reducing errors and improving inventory management.

- Automotive Industry: In the automotive sector, these counters are used to ensure the accuracy and reliability of electronic components, which is critical for safety and performance.

- Medical Device Manufacturing: In medical device manufacturing, SMT reel counters contribute to maintaining strict quality control standards by minimizing the risk of human errors and ensuring that medical devices are assembled with all required parts.

Challenges and Future Directions

Despite the numerous benefits of SMT component reel counters, there are challenges to their adoption, such as high initial investment costs. However, the long-term benefits often outweigh these costs by preventing costly rework, scrap, and product recalls, ultimately leading to significant cost savings and increased profitability for manufacturers.

The future of SMT reel counters will likely involve further advancements in technology, such as improved X-ray imaging techniques and enhanced AI capabilities. These advancements will continue to enhance the accuracy, efficiency, and reliability of component counting processes.

Real-World Applications and Success Stories

Companies like EE Technologies have already realized significant benefits from using advanced SMT reel counters. For instance, the XRHCount system has reduced bottlenecks in material return storage and eliminated redundant component purchases due to counting errors, thereby enhancing operational efficiency and reducing costs.

In addition, the integration of SMT reel counters with Industry 4.0 solutions, such as Fuji's Smart Factory, enables process control and efficiency gains, further highlighting the potential of these technologies in modern manufacturing environments.

Integration with Industry 4.0

The integration of SMT reel counters with Industry 4.0 technologies is a significant trend in modern manufacturing. Industry 4.0 emphasizes the use of smart machines and real-time data exchange to create more efficient and flexible production processes. By connecting SMT reel counters to IoT networks, manufacturers can achieve real-time monitoring and predictive maintenance, reducing downtime and enhancing operational efficiency.

For instance, VisiConsult's XRHCount system can be integrated into production lines using conveyor belts, allowing for fully automated loading and unloading processes. This automation not only reduces labor costs but also ensures that production lines operate continuously without interruptions.

DIY and Custom Solutions

For smaller-scale operations or educational purposes, DIY SMT component counters can be an economical and educational alternative. These devices can be built using components like stepper motors and gear systems, allowing for automatic counting and cutting of SMT reels. While these solutions may not offer the same level of precision as commercial systems, they provide a hands-on approach to understanding the principles behind component counting.

Future Trends

Looking ahead, future trends in SMT component reel counters will likely include further advancements in X-ray imaging techniques, such as phase-contrast X-ray imaging, which offers superior contrast and resolution compared to traditional methods. This technology will enable the detection of minute defects that would otherwise go unnoticed, ensuring the integrity and reliability of electronic devices.

Additionally, the integration of AI and ML will continue to enhance the capabilities of SMT reel counters, allowing for more accurate defect detection and real-time data analysis. These advancements will be crucial in meeting the demands of emerging technologies like 5G and IoT, which require highly compact and reliable components.

Conclusion

Innovations in SMT component reel counters are revolutionizing the electronics manufacturing industry by providing accurate, efficient, and cost-effective solutions for component counting. As technology continues to evolve, these counters will play an increasingly critical role in ensuring the precision and reliability of electronic component production. Whether through X-ray technology, AI integration, or Industry 4.0 connectivity, the future of SMT component reel counters is promising and will continue to shape the landscape of modern manufacturing.

FAQs

1. What is an SMT component reel counter?

An SMT component reel counter is a device used to accurately count the number of electronic components on a reel. These counters are essential for ensuring that the correct number of components are used in production, thereby improving inventory management and reducing errors.

2. How does an X-ray SMT reel counter work?

An X-ray SMT reel counter uses X-ray imaging to non-destructively analyze the contents of a reel. It emits an X-ray beam through the reel, creates an image of the components, and then uses advanced algorithms to identify and count individual components based on their shapes, sizes, and densities.

3. What are the benefits of using an SMT reel counter?

The benefits include accuracy, efficiency, non-destructive testing, quality control, and integration with management systems. These counters reduce labor costs, minimize errors, and enhance product quality by detecting internal defects.

4. How does AI integration improve SMT reel counters?

AI integration enhances the capabilities of SMT reel counters by enabling real-time data analysis, improving defect detection accuracy, and reducing false positives. AI-driven systems can adapt their detection criteria based on historical data, making inspections more reliable.

5. What industries use SMT component reel counters?

SMT component reel counters are used in various industries, including electronics manufacturing, the automotive sector, and medical device manufacturing. They are essential for maintaining high-quality standards and ensuring the reliability of electronic components.