Content Menu

● Introduction to PCB and SMT Technology

● Key Trends Shaping China PCB SMT Industry

>> 1. Automation and AI Integration

>> 2. Miniaturization and High-Density PCBs

>> 3. Green Manufacturing Practices

>> 4. 5G and IoT-Driven Innovations

● Challenges in China's PCB SMT Industry

● Future Outlook for China PCB SMT Technology

● Emerging Technologies in China PCB SMT

>> 1. 3D Printing in PCB Production

>> 2. Nanotechnology in PCB Manufacturing

>> 3. Quantum Computing PCBs

● The Role of China PCB SMT in Global Electronics Supply Chain

● Conclusion

● FAQs

>> 1. What is Surface Mount Technology (SMT)?

>> 2. Why is China a leader in PCB manufacturing?

>> 3. What role does AI play in China's PCB SMT industry?

>> 4. How does 5G impact China's PCB industry?

>> 5. What are green practices in China's PCB SMT industry?

China has solidified its position as the global leader in PCB (Printed Circuit Board) and SMT (Surface Mount Technology) manufacturing. With advancements in automation, green manufacturing, and the integration of cutting-edge technologies like AI and IoT, the industry is undergoing a transformative phase. This article explores the latest trends in China PCB SMT technology, highlighting innovations, challenges, and future prospects.

Introduction to PCB and SMT Technology

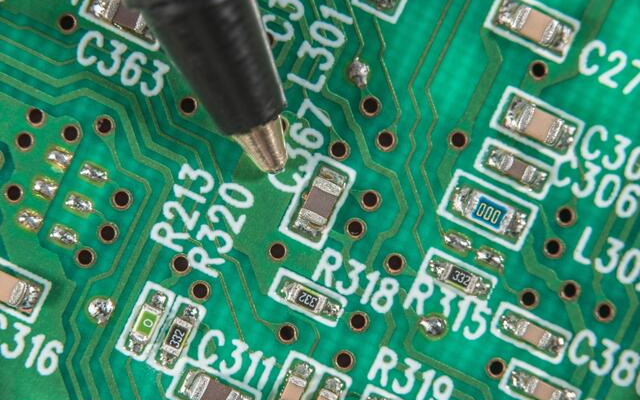

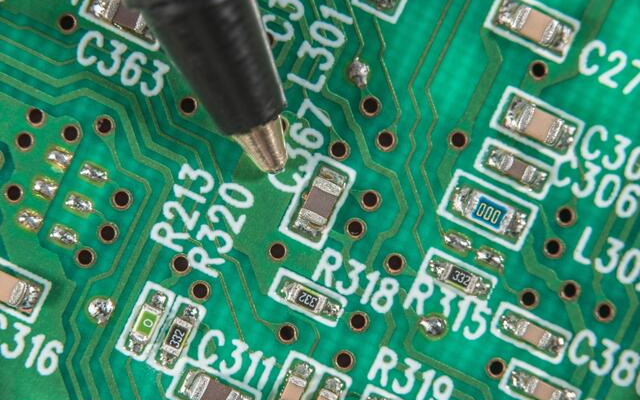

Printed Circuit Boards (PCBs) are the foundation of modern electronics, providing mechanical support and electrical connectivity for components. Surface Mount Technology (SMT) is a key assembly process where components are mounted directly onto the surface of PCBs, enabling compact designs and efficient manufacturing.

China dominates the global PCB production market, accounting for over 50% of global output. This leadership is driven by advanced manufacturing capabilities, cost efficiency, and a robust supply chain. The country's commitment to technological advancement and innovation has positioned it at the forefront of the PCB SMT industry.

Key Trends Shaping China PCB SMT Industry

1. Automation and AI Integration

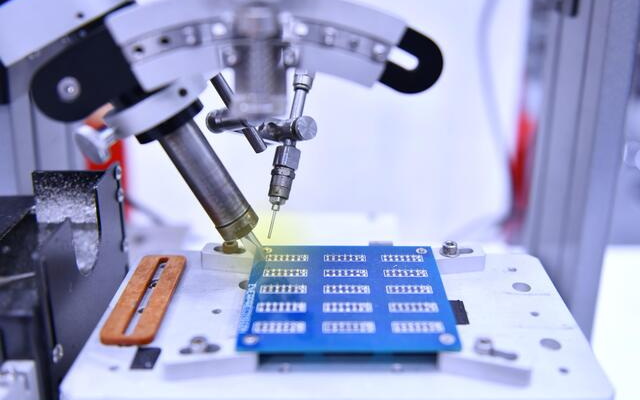

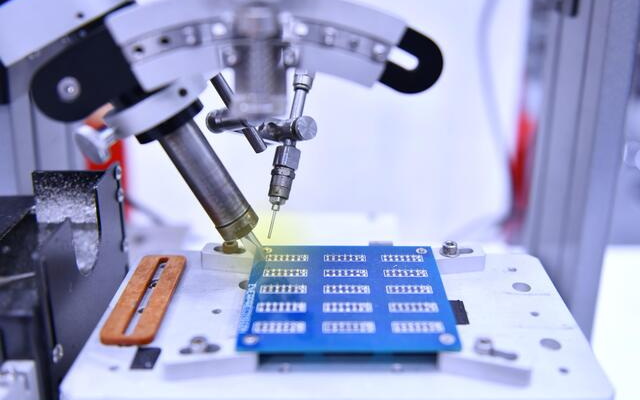

Automation has become indispensable in China's PCB SMT production lines:

- Pick-and-Place Machines: These machines precisely place thousands of components onto PCBs at high speeds, reducing human error and increasing throughput.

- AI-Powered Inspection Systems: Automated Optical Inspection (AOI) and X-ray systems detect defects with unparalleled accuracy, ensuring quality control at every stage of production.

- Industry 4.0: Real-time monitoring and predictive maintenance ensure minimal downtime and higher yields, optimizing overall production efficiency.

These advancements enhance efficiency while meeting the growing demand for high-quality electronics. The integration of AI in China PCB SMT manufacturing has led to significant improvements in defect detection rates, with some facilities reporting up to 99.9% accuracy in identifying potential issues before they impact final products.

2. Miniaturization and High-Density PCBs

The trend toward smaller electronic devices necessitates miniaturized components and high-density PCBs:

- Integrated Components: Sensors, capacitors, and resistors are now embedded directly into PCBs, reducing overall device size and improving performance.

- High-Density Interconnect (HDI) PCBs: These PCBs support advanced applications like smartphones, wearables, and medical devices, offering increased functionality in smaller form factors.

- Flexible PCBs: Widely used in foldable devices, these boards offer design versatility and are increasingly popular in automotive and aerospace applications.

China's manufacturers are at the forefront of developing these compact yet powerful solutions. The country's investment in research and development has led to breakthroughs in PCB design, enabling the production of boards with line widths as small as 30 microns and via holes as tiny as 50 microns in diameter.

3. Green Manufacturing Practices

Environmental sustainability is a growing priority in the China PCB SMT industry:

- Lead-Free Soldering: Reduces toxic waste during assembly processes, aligning with global environmental standards.

- Recyclable Materials: Manufacturers are adopting substrates that minimize environmental impact, such as biodegradable PCB materials.

- Energy Efficiency: Advanced production lines consume less energy while maintaining high output quality, reducing the carbon footprint of manufacturing processes.

These practices align with global regulations and consumer preferences for eco-friendly products. Many Chinese PCB manufacturers have obtained ISO 14001 certification, demonstrating their commitment to environmental management systems.

4. 5G and IoT-Driven Innovations

The rollout of 5G networks has spurred demand for advanced PCBs:

- RF PCBs: Designed to handle high-frequency signals required by 5G communication systems, these boards are crucial for next-generation mobile devices and infrastructure.

- Smart PCBs: Integrated with sensors to support IoT applications like smart homes and healthcare devices, enabling real-time data collection and analysis.

- Low-Loss Laminates: Minimize signal degradation in high-speed data transfer applications, essential for maintaining signal integrity in 5G and IoT devices.

China's expertise in material innovation ensures its leadership in these emerging markets. The country's PCB manufacturers are investing heavily in developing new materials and manufacturing processes to meet the stringent requirements of 5G and IoT applications.

Challenges in China's PCB SMT Industry

Despite its dominance, the industry faces several challenges:

1. Supply Chain Bottlenecks: High demand during peak seasons can strain resources, leading to potential delays and increased costs.

2. Labor Shortages: Skilled labor remains a critical issue during production surges, particularly for complex PCB designs requiring specialized expertise.

3. Rising Costs: Increasing material costs and stricter environmental regulations impact profitability, forcing manufacturers to seek innovative cost-reduction strategies.

Manufacturers are addressing these challenges through automation, streamlined processes, and strategic partnerships. Many China PCB SMT companies are investing in workforce training programs to develop a skilled labor pool capable of operating advanced manufacturing equipment.

Future Outlook for China PCB SMT Technology

The future of China's PCB SMT industry looks promising:

- The market is projected to grow at a compound annual growth rate (CAGR) of 4.3% from 2021 to 2026, reaching $54.6 billion by 2026.

- Emerging technologies like AI, machine learning, and Industry 4.0 will further enhance production efficiency, with some experts predicting fully autonomous PCB production lines within the next decade.

- The integration of smart manufacturing practices will enable real-time defect detection and predictive maintenance, reducing downtime and improving overall product quality.

China's commitment to innovation ensures its continued leadership in the global electronics market. The country's "Made in China 2025" initiative specifically targets high-tech industries, including PCB and SMT manufacturing, providing government support for research and development in these critical sectors.

Emerging Technologies in China PCB SMT

Several cutting-edge technologies are shaping the future of China PCB SMT manufacturing:

1. 3D Printing in PCB Production

3D printing technology is being explored for rapid prototyping and small-scale production of PCBs. This technology allows for quick iteration and testing of new designs, potentially revolutionizing the product development cycle.

2. Nanotechnology in PCB Manufacturing

Nanotechnology is being applied to create ultra-thin, high-performance PCBs. Nanomaterials can enhance conductivity, thermal management, and overall board performance, opening new possibilities for advanced electronic devices.

3. Quantum Computing PCBs

As quantum computing research progresses, Chinese manufacturers are exploring the development of PCBs capable of supporting quantum circuits. This emerging field could lead to revolutionary advancements in computing power and data processing capabilities.

The Role of China PCB SMT in Global Electronics Supply Chain

China's dominance in PCB SMT manufacturing plays a crucial role in the global electronics supply chain:

- Cost-Effective Production: China's efficient manufacturing processes and economies of scale allow for competitive pricing of PCBs and electronic components.

- Rapid Prototyping: The concentration of PCB manufacturers in China enables quick turnaround times for prototypes, accelerating product development cycles for companies worldwide.

- Customization Capabilities: Chinese manufacturers offer a wide range of customization options, catering to diverse industry needs from consumer electronics to aerospace applications.

The country's robust infrastructure and logistics networks further enhance its position as a key player in the global electronics industry.

Conclusion

The evolution of China's PCB SMT technology reflects broader trends in automation, miniaturization, sustainability, and connectivity. By embracing cutting-edge advancements like AI-driven inspection systems and green manufacturing practices, China remains at the forefront of this dynamic industry.

As consumer demand for smarter, smaller, and more sustainable electronics grows, China's PCB SMT manufacturers are well-positioned to meet these challenges head-on. The industry's continued investment in research and development, coupled with government support and a skilled workforce, ensures that China will maintain its leadership in PCB SMT technology for years to come.

The future of China PCB SMT is not just about maintaining current production levels but pushing the boundaries of what's possible in electronic manufacturing. From quantum computing PCBs to nanotechnology-enhanced boards, the innovations emerging from China's PCB industry will likely shape the future of global electronics, cementing the country's position as a technological powerhouse in the 21st century.

FAQs

1. What is Surface Mount Technology (SMT)?

SMT is a method where electronic components are mounted directly onto the surface of a printed circuit board (PCB), enabling compact designs and efficient assembly processes.

2. Why is China a leader in PCB manufacturing?

China leads due to its advanced manufacturing capabilities, cost-effective production processes, robust supply chains, and significant investment in R&D.

3. What role does AI play in China's PCB SMT industry?

AI enhances precision through automated inspection systems like AOI and X-ray machines while optimizing production efficiency via predictive maintenance.

4. How does 5G impact China's PCB industry?

5G drives innovation by increasing demand for RF PCBs designed for high-frequency data transfer applications essential for communication networks.

5. What are green practices in China's PCB SMT industry?

Green practices include lead-free soldering, recyclable materials, energy-efficient production lines, and adherence to environmental regulations.