Content Menu

● Overview of Universal Instruments

● Key Features of Universal Instruments SMT Line

>> Modular Design

>> Advanced Placement Technology

>> Comprehensive Software Solutions

>> Versatile Component Handling

>> High Reliability and Durability

● Benefits of Using Universal Instruments SMT Lines

>> Increased Productivity

>> Cost Efficiency

>> Enhanced Quality Control

>> Improved Time-to-Market

● Applications of Universal Instruments SMT Lines

>> Consumer Electronics

>> Automotive Industry

>> Medical Devices

● Future Trends in SMT Technology

>> Automation and Robotics

>> Industry 4.0 Integration

>> Miniaturization of Components

● Conclusion

● FAQ

>> 1. What is Surface Mount Technology (SMT)?

>> 2. How does modular design benefit manufacturers?

>> 3. What industries utilize Universal Instruments SMT lines?

>> 4. How does advanced placement technology improve production?

>> 5. What future trends are impacting SMT technology?

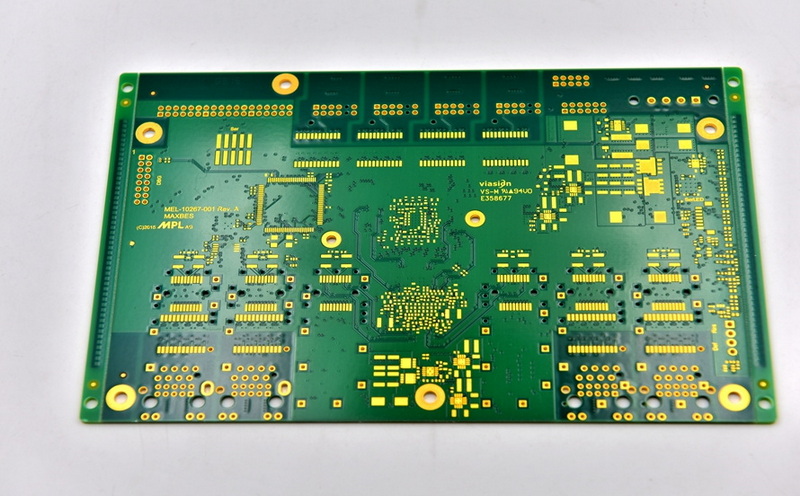

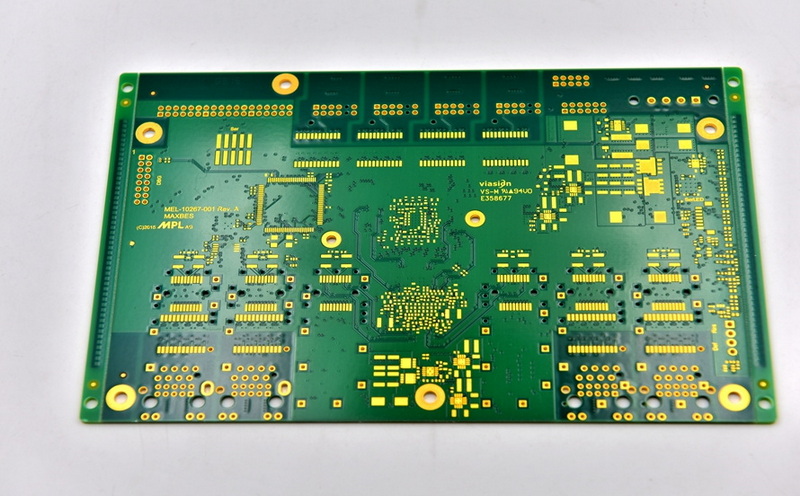

Surface Mount Technology (SMT) has revolutionized the electronics manufacturing industry by allowing for more compact and efficient assembly of electronic components. Universal Instruments is a prominent player in this field, offering a range of SMT line solutions that are known for their versatility, reliability, and advanced technology. This article explores the key features of Universal Instruments SMT lines, detailing their significance and applications in modern electronics manufacturing.

Overview of Universal Instruments

Universal Instruments has been a leader in the electronics manufacturing industry for decades. Established in 1919, the company has consistently innovated to meet the evolving needs of the market. Their SMT lines are designed to enhance productivity, reduce costs, and improve quality in electronic assembly processes.

The company's long-standing commitment to research and development has positioned it as a pioneer in SMT technology. Their solutions are not only tailored to meet current industry demands but are also forward-thinking, anticipating future trends and challenges in electronics manufacturing.

Key Features of Universal Instruments SMT Line

Universal Instruments SMT lines come equipped with several key features that set them apart from competitors. These features include:

Modular Design

One of the standout characteristics of Universal Instruments SMT lines is their modular design. This allows manufacturers to customize their production lines according to specific requirements.

- Flexibility: The modular approach enables easy upgrades and modifications, allowing manufacturers to adapt to changing production needs without significant downtime.

- Scalability: As production needs grow, additional modules can be integrated without overhauling the entire system. This scalability is crucial for companies looking to expand their operations without incurring excessive costs.

The modular design also facilitates easier maintenance and troubleshooting since individual modules can be serviced or replaced without affecting the entire line.

Advanced Placement Technology

Universal Instruments employs cutting-edge placement technology that ensures precise positioning of components on printed circuit boards (PCBs).

- High Speed: Their machines can place thousands of components per hour, significantly increasing throughput.

- Accuracy: Advanced vision systems assist in achieving high placement accuracy, minimizing defects. The use of intelligent algorithms helps in real-time adjustments during the placement process.

This advanced placement technology not only enhances productivity but also ensures that the final products meet stringent quality standards.

Comprehensive Software Solutions

The software solutions provided by Universal Instruments enhance the efficiency and effectiveness of their SMT lines.

- Real-Time Monitoring: Users can track production metrics and machine performance in real-time, allowing for immediate adjustments if necessary.

- Data Analysis: The software allows for in-depth analysis of production data, enabling continuous improvement. Manufacturers can identify bottlenecks and inefficiencies in their processes, leading to optimized workflows.

Additionally, these software solutions often come with user-friendly interfaces that make it easy for operators to navigate and utilize the full capabilities of the equipment.

Versatile Component Handling

Universal Instruments SMT lines are designed to handle a wide variety of components, from small passive devices to larger ICs.

- Component Flexibility: The machines can easily switch between different component types and sizes, accommodating diverse product lines.

- Feeder Options: Various feeder configurations allow for efficient loading and unloading of components. This versatility is essential for manufacturers who produce multiple products on the same line.

The ability to handle various components without extensive reconfiguration saves time and reduces operational costs.

High Reliability and Durability

Reliability is crucial in manufacturing environments, and Universal Instruments ensures that their SMT lines are built to last.

- Robust Construction: The machines are constructed with high-quality materials to withstand rigorous use over extended periods.

- Low Maintenance: Designed for minimal downtime, these machines require less frequent maintenance due to their durable construction and advanced engineering.

This reliability translates into higher productivity levels as manufacturers can depend on their equipment without worrying about unexpected breakdowns.

Benefits of Using Universal Instruments SMT Lines

The implementation of Universal Instruments SMT lines offers numerous benefits to manufacturers:

Increased Productivity

With high-speed placement capabilities and efficient workflows, these SMT lines significantly boost overall productivity. The combination of advanced technology and modular design allows for seamless scaling up or down based on demand fluctuations.

Cost Efficiency

By reducing waste and improving yield rates, manufacturers can achieve substantial cost savings over time. The ability to quickly switch between different product runs without extensive setup times further enhances cost efficiency.

Enhanced Quality Control

The advanced technology used in these machines contributes to higher quality products with fewer defects. Automated inspection systems integrated into the SMT lines ensure that any issues are detected early in the production process, allowing for immediate corrective actions.

Improved Time-to-Market

Faster production cycles enable companies to bring their products to market more quickly, gaining a competitive edge. This is particularly important in industries where technological advancements occur rapidly, necessitating swift responses from manufacturers.

Applications of Universal Instruments SMT Lines

Universal Instruments SMT lines are utilized across various sectors within the electronics industry:

Consumer Electronics

From smartphones to home appliances, these SMT lines are integral in producing reliable consumer electronic devices. The demand for smaller, more efficient devices has driven innovations within Universal Instruments' offerings tailored specifically for this sector.

Automotive Industry

As vehicles become increasingly reliant on electronics—such as sensors, control units, and infotainment systems—Universal Instruments plays a vital role in automotive component assembly. Their technology supports the stringent safety standards required in automotive manufacturing.

Medical Devices

Precision is critical in medical device manufacturing; Universal Instruments' technology ensures high standards are met while maintaining compliance with regulatory requirements. The ability to produce complex assemblies with high reliability is essential in this field.

Future Trends in SMT Technology

As technology continues to evolve, several trends are influencing the future of SMT lines:

Automation and Robotics

The integration of automation and robotics is set to enhance efficiency further, reducing labor costs and human error while improving consistency in production quality.

- Collaborative Robots (Cobots): These robots work alongside human operators, assisting with repetitive tasks while allowing humans to focus on more complex operations.

- Fully Automated Lines: Future developments may lead to fully automated SMT lines capable of operating with minimal human intervention.

Industry 4.0 Integration

Smart factories are becoming the norm, with interconnected systems allowing for seamless data exchange and real-time decision-making across various stages of production.

- IoT Connectivity: Equipment connected via the Internet of Things (IoT) enables predictive maintenance strategies that reduce downtime.

- Data Utilization: Manufacturers can leverage big data analytics for better forecasting and inventory management.

Miniaturization of Components

As electronics become smaller and more complex, SMT lines must adapt to handle increasingly miniaturized components effectively.

- Advanced Handling Systems: New technologies will be required to manage tiny components without damaging them during assembly.

- Precision Engineering: Enhanced precision engineering will be necessary to maintain quality standards as component sizes decrease further.

Conclusion

Universal Instruments' SMT lines represent a pinnacle of innovation in electronics manufacturing technology. With features such as modular design, advanced placement technology, comprehensive software solutions, versatile component handling, and high reliability, these systems meet the diverse needs of modern manufacturers across various industries. As trends like automation and Industry 4.0 continue to shape the landscape of electronics manufacturing, Universal Instruments remains at the forefront, providing solutions that enhance productivity, quality, and efficiency while addressing future challenges head-on.

FAQ

1. What is Surface Mount Technology (SMT)?

Surface Mount Technology (SMT) is a method used for producing electronic circuits where components are mounted directly onto the surface of PCBs instead of being inserted into holes.

2. How does modular design benefit manufacturers?

Modular design allows manufacturers to customize their production lines according to specific needs while enabling easy upgrades and scalability as production demands change.

3. What industries utilize Universal Instruments SMT lines?

Universal Instruments SMT lines are used across various sectors including consumer electronics, automotive manufacturing, and medical device production.

4. How does advanced placement technology improve production?

Advanced placement technology increases speed and accuracy in component placement on PCBs, resulting in higher productivity and reduced defect rates.

5. What future trends are impacting SMT technology?

Key trends include increased automation and robotics integration, Industry 4.0 advancements for smart factories, and the miniaturization of electronic components requiring more sophisticated handling techniques.