Content Menu

● Understanding Panasonic NPM Feeders

>> What are Panasonic NPM Feeders?

>> Types of Panasonic NPM Feeders

>> Technical Specifications

● Key Features of Panasonic NPM Feeders

>> High Speed and Efficiency

>> Flexibility in Component Handling

>> Advanced Technology Integration

>> User-Friendly Interface

● Benefits of Using Panasonic NPM Feeders

>> Improved Production Quality

>> Cost Efficiency

>> Enhanced Operational Flexibility

>> Reduced Downtime

● Case Studies: Success Stories with Panasonic NPM Feeders

>> Case Study 1: Increased Throughput at Electronics Manufacturer

>> Case Study 2: Reduced Defect Rates

>> Case Study 3: Streamlining Production Processes

● Challenges Addressed by Panasonic NPM Feeders

>> Handling Diverse Component Types

>> Adapting to Market Changes

● Conclusion

● Frequently Asked Questions (FAQs)

Understanding Panasonic NPM Feeders

What are Panasonic NPM Feeders?

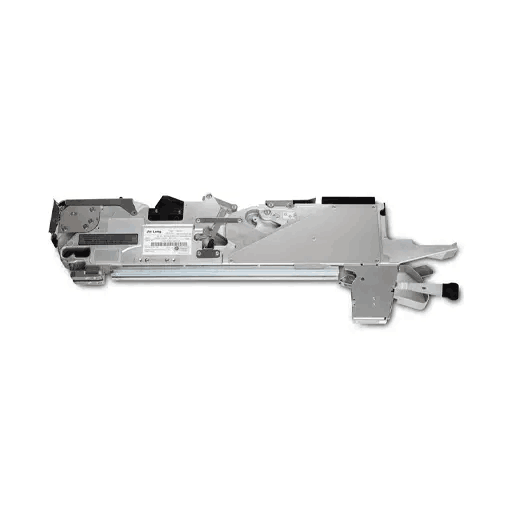

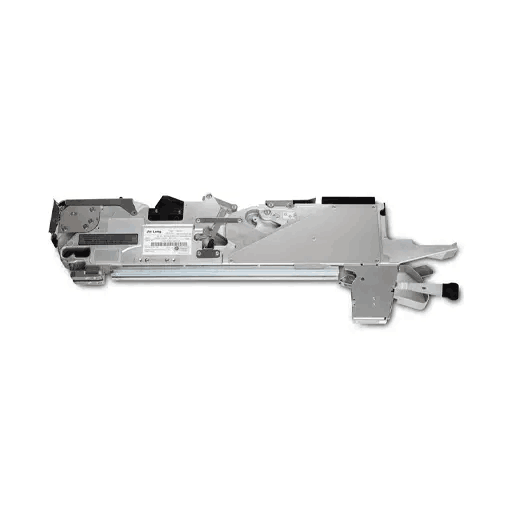

Panasonic NPM feeders are specialized devices designed to supply components to SMT machines during the assembly process. These feeders are integral to the operation of Panasonic's NPM series of pick-and-place machines, which are renowned for their speed and accuracy in placing surface mount devices (SMDs) onto printed circuit boards (PCBs).

Types of Panasonic NPM Feeders

Panasonic offers a variety of feeders compatible with its NPM machines, including:

- Tape Feeders: These are used for components supplied on tape, allowing for quick and efficient loading.

- Tray Feeders: Ideal for larger components that cannot be taped, such as connectors or larger ICs.

- Stick Feeders: Designed for long components such as connectors, these feeders can handle various lengths and sizes.

Technical Specifications

Panasonic NPM feeders come equipped with several technical features that enhance their functionality:

- Auto-adjustment Mechanism: This feature allows feeders to automatically adjust to different component sizes, reducing setup time significantly.

- High-capacity Storage: Many models can hold multiple reels or trays simultaneously, increasing the number of components available for continuous operation.

- Smart Control Systems: Advanced control systems enable real-time monitoring and adjustments based on production needs.

Key Features of Panasonic NPM Feeders

High Speed and Efficiency

One of the standout features of Panasonic NPM feeders is their ability to operate at high speeds. For instance, the latest models can achieve placement speeds of up to 43,000 chips per hour, significantly enhancing production rates. This high-speed operation is crucial in today's competitive market where time-to-market is a critical factor.

Flexibility in Component Handling

Panasonic feeders are designed to accommodate a wide range of component sizes and types. This flexibility allows manufacturers to handle various products without needing extensive adjustments or changes in setup. The ability to switch between different feeder types seamlessly means that manufacturers can quickly adapt to changing production requirements.

Advanced Technology Integration

The integration of advanced technologies such as vision systems enables precise component placement. This minimizes errors and reduces waste, contributing to overall production efficiency. Vision systems can detect misalignments and adjust placements in real time, ensuring that every component is placed accurately.

User-Friendly Interface

The user interface for Panasonic NPM feeders is designed with operators in mind. It provides intuitive controls and displays that make it easy for users to monitor operations, adjust settings, and troubleshoot issues quickly. This user-friendliness helps reduce training time for new operators and enhances overall productivity.

Benefits of Using Panasonic NPM Feeders

Improved Production Quality

With their high precision and reliability, Panasonic NPM feeders contribute to improved product quality. The accuracy in component placement ensures that electronic devices function as intended, reducing the likelihood of defects. High-quality production not only enhances customer satisfaction but also strengthens brand reputation.

Cost Efficiency

By maximizing throughput and minimizing errors, Panasonic NPM feeders help reduce manufacturing costs. The high-speed operation allows companies to meet tight deadlines without compromising quality. Additionally, fewer defects lead to lower rework costs and less material waste.

Enhanced Operational Flexibility

The ability to quickly switch between different types of components makes Panasonic feeders ideal for manufacturers who produce a variety of products. This operational flexibility is crucial in today's fast-paced market where demand can change rapidly. Manufacturers can easily adapt their production lines without significant downtime or reconfiguration costs.

Reduced Downtime

Panasonic NPM feeders are designed for reliability, which translates into reduced downtime during production runs. Features like quick-change setups allow operators to replace reels or trays swiftly without halting the entire line. This efficiency keeps production flowing smoothly and maximizes output.

Case Studies: Success Stories with Panasonic NPM Feeders

Case Study 1: Increased Throughput at Electronics Manufacturer

An electronics manufacturer reported a 30% increase in production throughput after integrating Panasonic NPM feeders into their SMT line. The combination of high-speed operation and flexibility allowed them to respond quickly to changing customer demands. By optimizing their feeder setup for different product lines, they could maintain high levels of productivity without sacrificing quality.

Case Study 2: Reduced Defect Rates

Another company noted a significant reduction in defect rates after switching to Panasonic feeders. The precise placement capabilities ensured that components were consistently positioned correctly, leading to fewer failures during testing. This improvement not only enhanced product reliability but also reduced warranty claims and increased customer trust.

Case Study 3: Streamlining Production Processes

A mid-sized electronics firm implemented Panasonic NPM feeders as part of an overall strategy to streamline its production processes. By utilizing the auto-adjustment feature, they reduced setup times by nearly 50%. This efficiency gain allowed them to increase their product offerings without needing additional labor or equipment investments.

Challenges Addressed by Panasonic NPM Feeders

Handling Diverse Component Types

In modern electronics manufacturing, products often require a wide variety of components ranging from tiny resistors to large capacitors. Panasonic NPM feeders excel in this area by providing solutions that accommodate diverse component types without extensive reconfiguration.

Adapting to Market Changes

The electronics market is characterized by rapid changes in consumer preferences and technology advancements. Manufacturers need equipment that can adapt quickly to these changes. The flexibility offered by Panasonic NPM feeders allows companies to pivot their production strategies effectively.

Conclusion

The adoption of Panasonic NPM feeders in SMT production lines represents a strategic investment for manufacturers aiming to enhance efficiency and product quality. With their advanced features, flexibility, and proven success in real-world applications, these feeders are essential tools for any electronics assembly operation. As technology continues to evolve, staying ahead with reliable equipment like Panasonic NPM feeders will be crucial for maintaining competitive advantage in the electronics industry.

Frequently Asked Questions (FAQs)

1. What is the maximum speed of Panasonic NPM feeders?

- The maximum speed can reach up to 43,000 chips per hour depending on the model used.

2. Can Panasonic NPM feeders handle different component types?

- Yes, they can accommodate various component types including tape-fed, tray-fed, and stick-fed components.

3. How do Panasonic feeders improve production quality?

- Their high precision reduces placement errors, which enhances overall product quality and reliability.

4. What are the benefits of using multiple feeder types?

- Using different feeder types allows manufacturers to handle a wider range of components efficiently without extensive setup changes.

5. Are there any case studies demonstrating the effectiveness of these feeders?

- Yes, several manufacturers have reported increased throughput and reduced defect rates after implementing Panasonic NPM feeders in their production lines.