Content Menu

● Regular Maintenance and Cleaning

● Optimize Feeder Setup

● Monitor Feeder Performance Metrics

● Invest in Quality Components

● Train Operators Effectively

● Implement Inline Inspection Systems

● Automate Material Handling Processes

● Conclusion

● FAQ

>> 1. What is an SMT feeder?

>> 2. How often should I clean my SMT feeders?

>> 3. What are common issues faced with SMT feeders?

>> 4. How can I tell if my SMT feeder needs maintenance?

>> 5. Is operator training really necessary for SMT feeder performance?

● Citations:

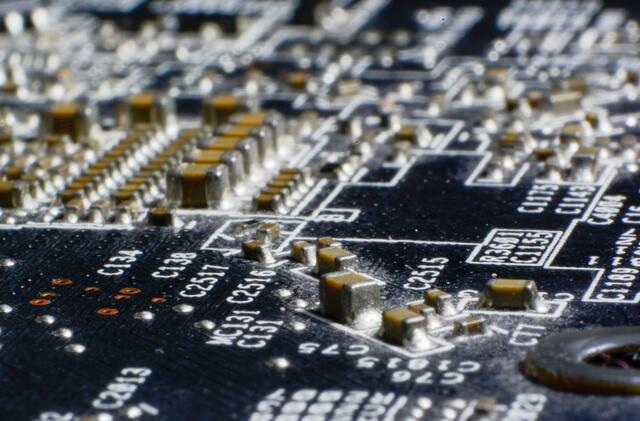

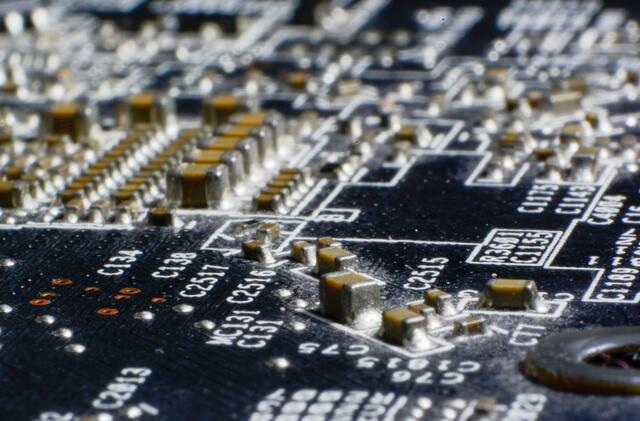

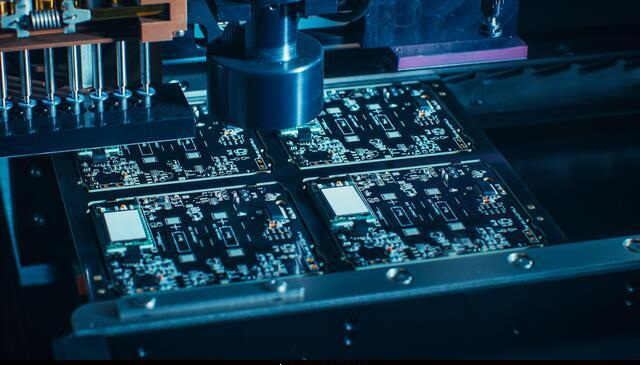

Surface Mount Technology (SMT) feeders are integral to the efficiency and accuracy of PCB assembly processes. As the electronics industry demands faster production and higher quality, optimizing SMT feeder performance becomes essential for manufacturers. This article presents five comprehensive steps to enhance SMT feeder performance, ensuring smooth and efficient production lines.

Regular Maintenance and Cleaning

Regular maintenance and cleaning are crucial for improving SMT feeder performance. Accumulated dust, debris, and solder paste residues can lead to malfunctions and reduced efficiency. Here are some detailed maintenance practices:

- Scheduled Cleaning: Establish a routine cleaning schedule for your feeders. Use appropriate cleaning solutions that do not damage feeder components. This should include cleaning nozzles, belts, and sensors to prevent blockages.

- Inspect Components: Conduct regular inspections of feeder components for wear and tear. This includes checking for any signs of damage or misalignment that could affect performance.

- Lubrication: Ensure that all moving parts are adequately lubricated to minimize friction and prevent mechanical failures. Regularly check lubrication levels based on the manufacturer's recommendations.

- Replace Worn Parts: Identify and replace any worn or damaged parts promptly to avoid further issues down the line. Keeping a stock of essential spare parts can facilitate quick repairs.

By maintaining clean and well-functioning feeders, manufacturers can significantly reduce downtime caused by equipment failures.

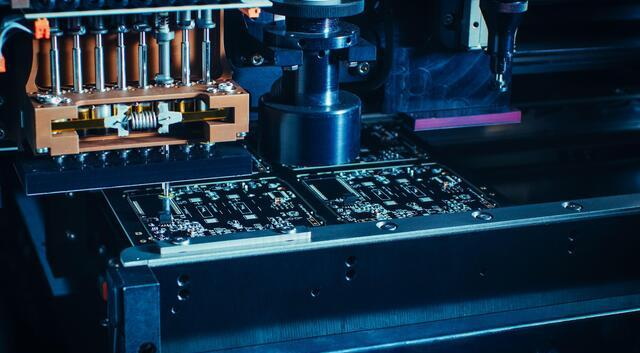

Optimize Feeder Setup

The setup of SMT feeders significantly influences their performance. An optimized feeder setup ensures accurate and consistent component feeding. Consider the following strategies:

- Correct Component Placement: Ensure that components are placed correctly in the feeder pockets. Misalignment can lead to feeding errors, increasing cycle times.

- Proper Feeder Calibration: Regularly calibrate feeders to ensure they operate within specified tolerances. This includes adjusting the height and angle of the feeders as needed to match the requirements of different components.

- Utilize Automation: Implement automation tools that can quickly configure feeders for different component types, reducing manual setup time and potential errors.

- Feeder Arrangement: Strategically arrange feeders to minimize pick-up distances. Group similar components together to enhance efficiency during operation.

An optimized setup reduces errors during assembly, improving overall throughput and productivity.

Monitor Feeder Performance Metrics

Continuous monitoring of key performance metrics is essential for enhancing SMT feeder performance. By analyzing these metrics, manufacturers can identify areas for improvement:

- Feed Rate: Measure how quickly components are fed into the pick-and-place machine. A consistent feed rate is vital for maintaining production speed.

- Error Rate: Track the number of feeding errors or misplacements per cycle. High error rates indicate a need for adjustments in setup or maintenance.

- Downtime Analysis: Record instances of downtime related to feeder issues. Understanding the causes of downtime helps implement preventive measures.

- Utilize Data Analytics: Employ data analytics tools to gain insights into feeder performance trends, allowing for timely interventions based on empirical data rather than guesswork.

By closely monitoring these metrics, manufacturers can make informed decisions that enhance feeder efficiency and overall production quality.

Invest in Quality Components

The quality of SMT feeders directly impacts their performance. Investing in high-quality components leads to significant improvements in reliability and efficiency:

- Choose Reputable Brands: Select feeders from well-known manufacturers with a proven track record of quality and reliability. Research user reviews and industry feedback before making a purchase.

- Upgrade Parts: Consider upgrading specific parts of your feeders, such as nozzles or drive systems, with higher-quality alternatives that offer better precision and durability.

- Stay Updated on Technology: Keep abreast of technological advancements in SMT feeding systems. Newer models may incorporate features that enhance performance, such as improved sensors or faster feeding mechanisms.

- Quality Control Checks: Implement stringent quality control checks on incoming materials and components to ensure they meet required standards before being used in production.

Investing in quality components not only improves performance but also reduces long-term operational costs associated with repairs and replacements.

Train Operators Effectively

The skill level of operators plays a significant role in SMT feeder performance. Proper training ensures operators understand how to use equipment effectively and troubleshoot common issues:

- Comprehensive Training Programs: Develop training programs covering all aspects of SMT feeder operation, including setup, troubleshooting, and maintenance procedures.

- Hands-On Experience: Provide operators with hands-on experience under the supervision of experienced personnel. Practical training reinforces theoretical knowledge and builds confidence in handling equipment.

- Continuous Learning Opportunities: Encourage operators to pursue continuous learning through workshops or online courses related to SMT technology advancements.

- Cross-Training Staff: Cross-train operators on multiple machines or processes within the assembly line to create a more flexible workforce capable of adapting to various tasks as needed.

Well-trained operators can identify potential issues early on, maintaining optimal feeder performance throughout production runs.

Implement Inline Inspection Systems

Integrating inline inspection systems into your SMT processes can significantly enhance quality control while improving overall efficiency:

- Automated Defect Detection: Use cameras and sensors to inspect PCBs as they exit the SMT machine, detecting defects like component misalignment or insufficient solder paste application without manual intervention.

- Real-Time Feedback Loop: Establish a real-time feedback loop where inspection results inform immediate adjustments in the production process, reducing rework rates and improving output quality.

- Data Collection for Continuous Improvement: Collect data from inline inspections to identify recurring issues or trends over time, allowing for targeted improvements in both processes and equipment setups.

Implementing inline inspection systems not only increases quality control but also reduces operator workload by minimizing manual inspections throughout production runs.

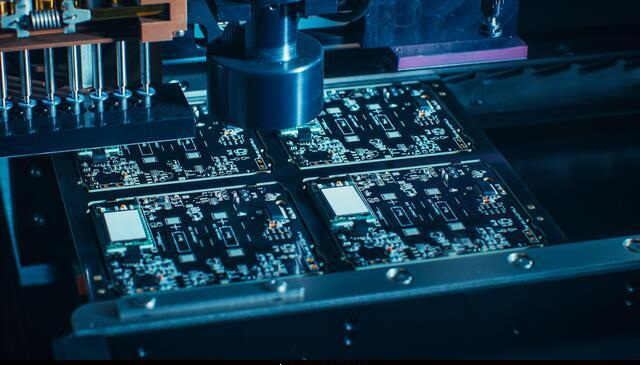

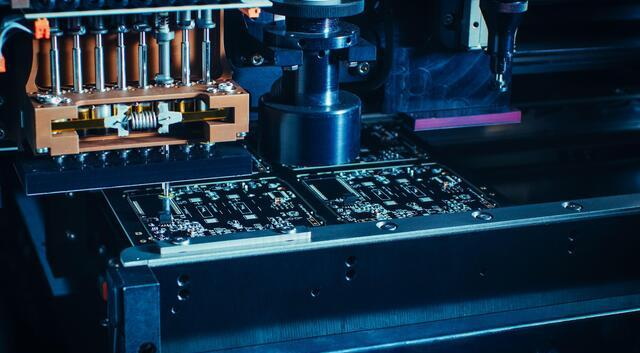

Automate Material Handling Processes

Automating material handling processes can further increase SMT mounter efficiency by streamlining operations:

- Automated Feeder Changeover: Implement systems that automate the component feeder changeover process, reducing downtime associated with manual changes between different component types.

- Material Management Systems: Utilize material management software that tracks inventory levels in real-time, ensuring timely replenishment of components without halting production lines due to shortages.

- Automatic Guided Vehicles (AGVs): Deploy AGVs for transporting materials between different stages of production efficiently, minimizing manual labor while enhancing safety protocols within manufacturing facilities.

Automation reduces manual intervention across various processes, leading to increased material uptime and improved overall production efficiency.

Conclusion

Improving SMT feeder performance is critical for enhancing manufacturing efficiency and product quality in today's fast-paced electronics industry. By implementing regular maintenance practices, optimizing setups, monitoring performance metrics, investing in quality components, providing effective operator training, integrating inline inspection systems, and automating material handling processes, manufacturers can achieve substantial gains in productivity and reliability. These seven comprehensive steps not only streamline operations but also contribute to a robust production environment capable of meeting modern electronic assembly demands effectively.

FAQ

1. What is an SMT feeder?

An SMT feeder is a device used in surface mount technology assembly processes to supply electronic components accurately to pick-and-place machines during PCB assembly operations.

2. How often should I clean my SMT feeders?

It is recommended to clean SMT feeders regularly based on usage frequency; typically, a weekly or bi-weekly cleaning schedule is effective for maintaining optimal performance levels.

3. What are common issues faced with SMT feeders?

Common issues include misalignment of components during feeding, feeding errors due to debris buildup within the system, mechanical failures from lack of maintenance attention, and incorrect calibration settings leading to operational inefficiencies.

4. How can I tell if my SMT feeder needs maintenance?

Signs that your SMT feeder may need maintenance include increased error rates during assembly cycles, unusual noises emitted during operation indicating mechanical strain, or inconsistent feed rates compared to historical operational benchmarks indicating potential issues requiring attention.

5. Is operator training really necessary for SMT feeder performance?

Yes! Operator training is crucial as it equips personnel with necessary knowledge about operating equipment efficiently while enabling them to troubleshoot issues effectively; this ultimately enhances optimal performance levels throughout production runs while reducing downtime caused by human error or oversight.

Citations:

[1] https://www.zjyingxing.com/info/what-are-the-ways-to-improve-the-efficiency-of-88896111.html

[2] https://www.raypcb.com/smt-assembly-process-optimization-by-multi-head-gantry-type-chip-mounter/

[3] https://www.zjyingxing.com/info/what-are-smt-related-tips-93976082.html

[4] https://www.raypcb.com/effective-measures-to-improve-smt-assembly-quality/

[5] https://cdn.aaai.org/FLAIRS/2008/FLAIRS08-130.pdf

[6] https://txjpcb.com/the-best-practices-for-smt-line-balancing-and-optimization/

[7] https://www.adoptsmt.com/en/efficiency-enhancement-in-smt-manufacturing/

[8] https://www.tronstol.com/how-to-optimize-smt-mounter-machine-equipment.html

[9] https://asselems.com/en/best-practices-in-smt-assembly

[10] https://www.neodensmt.com/news/improve-smt-production-efficiency-48868013.html