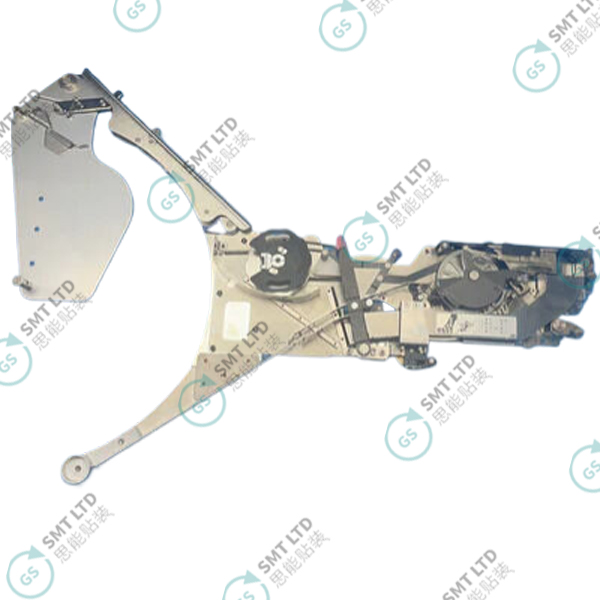

JUKI 32MM FTFR SERIES DEEP POCKET FEEDER FF32FR E6000706RBB E6000-706-RBB

Brand Name :JUKI

Product name:Feeder

Model Number:FF32FR,E6000706RBB,E6000-706-RBB

Condition:original new/compatible new/used original

Lead time:1-3 Days

MOQ : 1 PCS

Material throwing by an SMT (Surface Mount Technology) placement machine refers to the unintentional displacement or ejection of components during the assembly process. This issue can result in production defects, machine downtime, and increased material waste. Analyzing and treating the causes of material throwing requires a systematic approach. Here's how to address this problem:

1.Inspect Feeder Setup: Ensure that the feeders are properly set up and aligned with the placement machine. Misaligned or improperly loaded feeders can cause components to be fed inaccurately, leading to throwing issues. Check feeder alignment, tape tension, and component orientation to ensure proper feeding.

2.Check Feeder Calibration: Verify that the feeders are calibrated correctly according to the manufacturer's specifications. Incorrect feeder calibration settings can cause feeding errors and material throwing. Adjust feeder calibration parameters such as pitch, speed, and pickup position as needed.

3.Inspect Component Tape: Examine the component tape for any signs of damage, wrinkles, or misalignment that may interfere with component feeding. Ensure that the cover tape is securely sealed and properly aligned with the feeder. Replace damaged or improperly loaded component tape as necessary.

4.Review Component Specifications: Confirm that the components being used are compatible with the feeder and placement machine. Components that are too large, too small, or irregularly shaped may not feed properly and can cause material throwing. Verify component dimensions, package type, and lead pitch against machine specifications.

5.Check Component Handling: Evaluate the handling of components during the assembly process. Excessive vibration, static electricity, or improper handling can cause components to become dislodged or thrown from the machine. Implement ESD (Electrostatic Discharge) protection measures and proper handling procedures to minimize these risks.

6.Inspect Nozzle Condition: Examine the condition of the placement nozzles for signs of wear, damage, or contamination. Worn or damaged nozzles can cause improper component pickup and placement, leading to material throwing. Clean or replace nozzles as needed to ensure proper operation.

7.Review Machine Settings: Check the machine settings and parameters related to component pickup and placement. Adjust settings such as vacuum strength, pickup height, and placement force to optimize component handling and reduce throwing issues.

8.Address Machine Vibrations: Minimize machine vibrations by ensuring that the placement machine is properly leveled and securely mounted. Vibrations can cause components to shift or become dislodged during the assembly process, leading to material throwing.

9.Implement Vision Inspection: Consider implementing vision inspection systems to detect and correct placement errors in real-time. Vision systems can identify misaligned or improperly placed components before they cause material throwing, reducing scrap and rework.

10.Monitor and Test: Regularly monitor the placement machine during production runs to detect any signs of material throwing. Conduct test runs with different component types and feeder setups to identify and address potential issues proactively.

11.Training and Documentation: Provide training to operators on proper machine setup, calibration, and maintenance procedures. Document troubleshooting steps and solutions for material throwing issues to facilitate future problem-solving.

By systematically analyzing and treating the causes of material throwing by an SMT placement machine, you can improve assembly quality, minimize downtime, and optimize production efficiency. Continuously monitor and adjust machine parameters and processes to maintain reliable operation and reduce the risk of material throwing.

Hot tags:Juki feeder FF32FR,smt Juki feeder FF32FR,Juki FF32FR tape feeder,Juki E6000706RBB component feeder,Juki E6000706RBB feeder specifications,Juki E6000706RBB feeder compatibility,Juki E6000-706-RBB feeder setup,Juki E6000-706-RBB feeder calibration,Juki FF32FR feeder maintenance,Juki FF32FR feeder parts,china,wholesale, cheap, low price, manufacturers, factory, suppliers, for sale, in stock