Content Menu

● Introduction to SMD Mounting Machines

>> Advantages of China SMD Mounting Machines

● Strategies to Improve Efficiency

● Key Features of China SMD Mounting Machines

● Integration with Modern Technologies

>> Role of Automation in PCB Assembly

● Choosing the Right China SMD Mounting Machine

● Advanced Techniques in PCB Assembly

● Future Trends in SMD Mounting Machines

● Conclusion

● Frequently Asked Questions

>> 1. What are the key advantages of using China SMD mounting machines?

>> 2. How can I optimize the SMT process for better efficiency?

>> 3. What role does automation play in improving PCB assembly efficiency?

>> 4. How do inline inspection systems contribute to efficiency?

>> 5. What future trends should I consider when investing in SMD mounting machines?

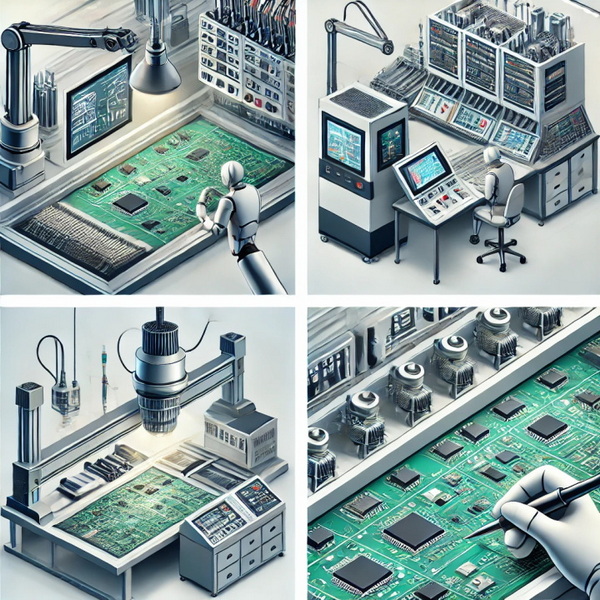

In the rapidly evolving electronics manufacturing industry, efficiency and precision are crucial for maintaining competitiveness. Surface Mount Technology (SMT) has become a cornerstone of modern PCB assembly, allowing for faster, more precise, and cost-effective production. China has emerged as a leading manufacturer of SMD mounting machines, offering high-quality equipment at competitive prices. This article explores how to improve PCB assembly efficiency using a China SMD mounting machine, focusing on key strategies and technologies.

Introduction to SMD Mounting Machines

SMD mounting machines, also known as pick-and-place machines, are essential in the PCB assembly process. They automate the placement of surface mount components onto printed circuit boards (PCBs), ensuring high precision and speed. These machines are designed to handle a wide range of components, from small chip resistors to large integrated circuits, making them versatile for various applications.

Advantages of China SMD Mounting Machines

China's SMD mounting machines are renowned for their high-speed placement capabilities, precision and accuracy, and user-friendly interfaces. They are capable of placing thousands of components per hour, significantly boosting production efficiency. Additionally, these machines are designed with flexibility in mind, allowing them to handle a variety of components and production volumes.

Strategies to Improve Efficiency

Improving PCB assembly efficiency with a China SMD mounting machine involves several strategic approaches:

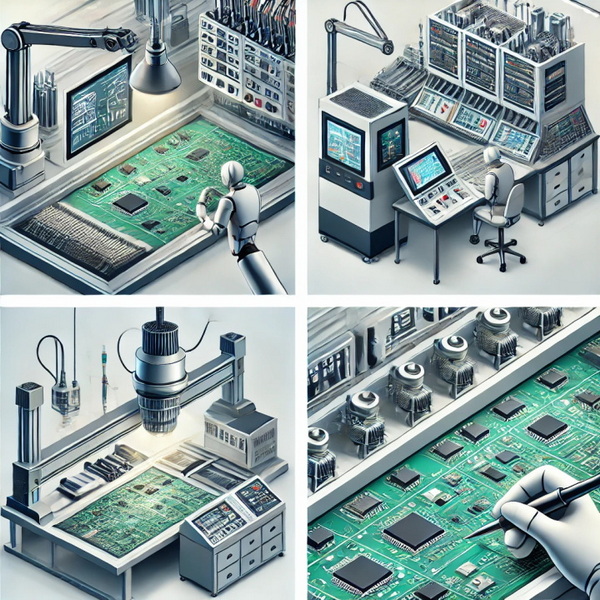

1. Invest in High-Speed Placement Machines: High-speed placement machines are crucial for increasing production output. They utilize advanced technologies such as laser alignment and multi-head placement systems to mount components quickly and accurately. These machines can significantly reduce the time taken for mounting components, eliminate the need for operator intervention, and improve placement accuracy.

2. Optimize the SMT Process: Optimizing the SMT process involves selecting the right component feeders, optimizing placement parameters, using the right solder paste, and choosing appropriate pick and place heads. Manufacturers can also optimize the production sequence by grouping similar components together, using common feeders, and reducing the number of machine tooling changes. This approach enhances efficiency by minimizing downtime and maximizing machine utilization.

3. Implement Inline Inspection Systems: Inline inspection systems use cameras and sensors to detect defects on the PCB, such as component misalignment or insufficient solder paste. Implementing these systems increases quality control and reduces the workload of operators since they do not have to manually inspect every PCB. This also reduces the risk of rework and improves production efficiency by minimizing downtime for repairs.

4. Automate Material Handling: Automating the material handling process, including feeder changeovers and material transport, reduces manual intervention and increases material uptime. This can be achieved using automatic guided vehicles (AGVs) and material management systems. Automation in material handling not only reduces changeover time but also improves overall production efficiency by ensuring continuous operation.

5. Train Operators Effectively: Well-trained operators are essential for maximizing machine performance. Training should cover machine operation, fault identification, minor repairs, and optimizing machine settings. With well-trained operators, the SMT machine can perform at its optimal level, reducing downtime, increasing quality, and improving production efficiency.

Key Features of China SMD Mounting Machines

China SMD mounting machines are distinguished by several key features:

- High-Speed Placement: These machines can place components at speeds of thousands per hour, making them ideal for large-scale production. Some advanced models can achieve placement rates of up to 250,000 components per hour.

- Precision and Accuracy: Advanced vision systems and precise mechanics ensure components are placed accurately on the PCB. The precision placement capabilities of these machines are impressive, with placement tolerances as low as 0.01mm.

- User-Friendly Interfaces: Intuitive interfaces make it easier for operators to learn and maximize the machine's potential. Many machines feature vision teach-in programming capabilities, allowing operators to easily program new component placements.

- Flexibility in Component Handling: These machines can handle a wide range of components, from small to large, making them suitable for diverse production needs. They typically offer a variety of feeder options to accommodate different component packaging types.

Integration with Modern Technologies

The future of SMD mounting machines involves integration with modern technologies such as Artificial Intelligence (AI) and Machine Learning (ML). These technologies can enhance component placement accuracy, optimize production processes, and predict maintenance needs. Additionally, the adoption of Industry 4.0 and IoT technologies allows for real-time monitoring and remote control, further enhancing efficiency and scalability.

Role of Automation in PCB Assembly

Automation plays a pivotal role in improving PCB assembly efficiency. Automated pick-and-place machines can dramatically reduce assembly time while increasing accuracy. By automating processes like soldering and inspection, manufacturers can avoid human errors that could lead to defects, ensuring a more robust final product. Automated Optical Inspection (AOI) systems swiftly scan and inspect PCBs for errors, providing immediate feedback to the production line and allowing for quick corrections.

Choosing the Right China SMD Mounting Machine

When selecting a China SMD mounting machine, several factors should be considered:

- Production Volume: Choose a machine that matches your production needs, whether high-speed for large volumes or mid-range for smaller operations.

- Component Variety: Ensure the machine can handle the range of components you plan to use.

- Budget: Determine your budget and look for machines offering the best value for money.

- Technical Support: Reliable technical support is crucial for smooth operation and maintenance.

- Integration Capabilities: Consider whether the machine can be integrated into existing production lines or future expansions.

Advanced Techniques in PCB Assembly

In addition to optimizing machine performance, advanced techniques in PCB assembly can further enhance efficiency and precision. Techniques such as reflow soldering and wave soldering ensure that all components are bonded securely, minimizing the risk of defects. Utilizing precise pick-and-place systems enables accurate placement of components, which is crucial for maintaining alignment across densely populated boards. The application of optical inspection systems further enhances precision by allowing real-time monitoring of solder joints and component alignment.

Future Trends in SMD Mounting Machines

As technology continues to evolve, the integration of Artificial Intelligence (AI) and Machine Learning (ML) will become increasingly important. AI can optimize production processes by predicting component placement errors and adjusting machine settings in real-time. ML algorithms can analyze production data to identify patterns and improve efficiency by optimizing component feeders and placement sequences. These technologies will enable SMD mounting machines to adapt to changing production demands more effectively.

Moreover, the adoption of Industry 4.0 and IoT technologies will allow for seamless integration of SMD mounting machines with other equipment in the production line. Real-time monitoring and remote control capabilities will enhance efficiency by enabling immediate adjustments to production parameters and predictive maintenance, reducing downtime and improving overall productivity.

In conclusion, embracing these future trends will be crucial for manufacturers seeking to maintain a competitive edge in the electronics industry. By integrating advanced technologies and optimizing production processes, companies can ensure that their SMD mounting machines operate at peak efficiency, delivering high-quality PCBs while meeting the demands of an ever-evolving market.

Conclusion

Improving PCB assembly efficiency with a China SMD mounting machine involves a combination of strategic approaches and leveraging the advanced features of these machines. By investing in high-speed placement machines, optimizing the SMT process, implementing inline inspection systems, automating material handling, and training operators effectively, manufacturers can significantly enhance their production capabilities. As the electronics manufacturing industry continues to evolve, China SMD mounting machines are poised to play a central role in meeting the demands for precision, speed, and flexibility.

Frequently Asked Questions

1. What are the key advantages of using China SMD mounting machines?

- China SMD mounting machines offer high-speed placement, precision and accuracy, user-friendly interfaces, and flexibility in handling a wide range of components. They are also competitively priced, making them an attractive option for manufacturers seeking to enhance production efficiency without compromising on quality.

2. How can I optimize the SMT process for better efficiency?

- Optimizing the SMT process involves selecting the right component feeders, optimizing placement parameters, using the right solder paste, and choosing appropriate pick and place heads. Additionally, grouping similar components together and minimizing machine tooling changes can enhance efficiency.

3. What role does automation play in improving PCB assembly efficiency?

- Automation, particularly in material handling and inspection, reduces manual intervention, increases material uptime, and minimizes the risk of rework. This leads to higher production efficiency and better quality control.

4. How do inline inspection systems contribute to efficiency?

- Inline inspection systems use cameras and sensors to detect defects on the PCB, reducing manual inspection time and the risk of rework. This enhances quality control and improves overall production efficiency by minimizing downtime for repairs.

5. What future trends should I consider when investing in SMD mounting machines?

- Future trends include the integration of AI and ML for enhanced accuracy and process optimization, adoption of Industry 4.0 and IoT for real-time monitoring, and a focus on sustainability and miniaturization. These trends will shape the future of electronics manufacturing and influence the design and functionality of SMD mounting machines.