Content Menu

● Understanding SMT Components

● List of Common SMT Components

● Identifying SMT Components

>> Resistors

>> Capacitors

>> Inductors

>> Diodes

>> Transistors

>> Integrated Circuits (ICs)

● Common Packaging Types

● Applications of SMT Components

● Challenges in Identifying SMT Components

● Best Practices for Working with SMT Components

● Conclusion

● FAQ

>> 1. What are the main differences between passive and active SMT components?

>> 2. How can I identify SMD resistors?

>> 3. What is the significance of component packaging in SMT?

>> 4. Are there any specific tools needed to identify SMT components?

>> 5. Can I use through-hole components instead of SMT ones?

● Citations:

Surface Mount Technology (SMT) has revolutionized the electronics industry by allowing for the miniaturization of components and efficient assembly processes. Understanding how to identify different types of SMT components is crucial for anyone involved in electronics design, manufacturing, or repair. This article will provide a comprehensive overview of SMT components, including their types, identification methods, and practical applications.

Understanding SMT Components

SMT components are electronic devices designed to be mounted directly onto the surface of printed circuit boards (PCBs). Unlike traditional through-hole components, which require holes to be drilled into the PCB, SMT components are soldered directly onto the board's surface. This allows for a more compact design and higher density of components on a PCB.

The advantages of SMT over traditional methods include:

- Size Reduction: SMT components are generally smaller than their through-hole counterparts, enabling more compact circuit designs.

- Increased Reliability: The solder joints in SMT are less prone to mechanical stress and fatigue compared to through-hole connections.

- Higher Component Density: SMT allows for a greater number of components to be placed on a single PCB, which is essential for modern electronic devices that require complex functionalities.

- Automated Assembly: SMT is compatible with automated assembly techniques, leading to faster production times and reduced labor costs.

List of Common SMT Components

1. Resistors: Limit current flow within a circuit. They come in various forms such as thick film and thin film resistors.

2. Capacitors: Store electrical energy temporarily. Common types include ceramic capacitors and tantalum capacitors.

3. Inductors: Store energy in a magnetic field when current flows through them. They are essential for filtering applications.

4. Diodes: Allow current to flow in one direction only, protecting circuits from reverse polarity.

5. Transistors: Used for switching and amplification of signals.

6. Integrated Circuits (ICs): Complex devices that combine multiple functions into a single package.

7. Connectors: Facilitate temporary or permanent connections between different parts of a circuit.

8. Crystal Oscillators: Provide stable clock signals for timing applications.

9. LEDs (Light Emitting Diodes): Used for indication and display purposes; they are available in various colors and sizes.

10. Microcontrollers: Compact integrated circuits that can be programmed to perform specific tasks in embedded systems.

Identifying SMT Components

Identifying SMT components involves understanding their physical characteristics and packaging styles. Here are some tips for recognizing various types of SMT components:

Resistors

- Appearance: Typically rectangular with two terminals on either end.

- Identification Marks: Often marked with a three- or four-digit code indicating resistance value.

- Color Codes: In some cases, color bands may be used to indicate resistance values, although this is less common in SMT resistors compared to through-hole types.

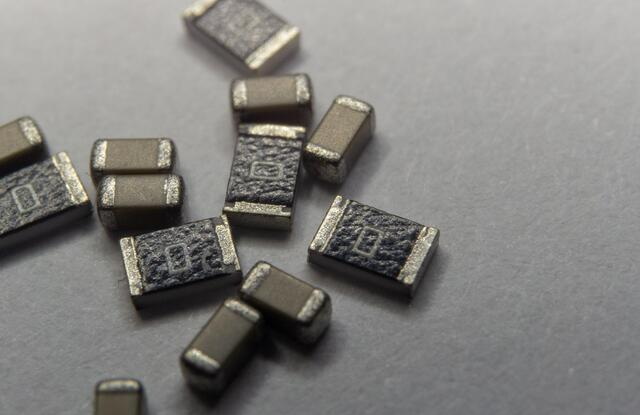

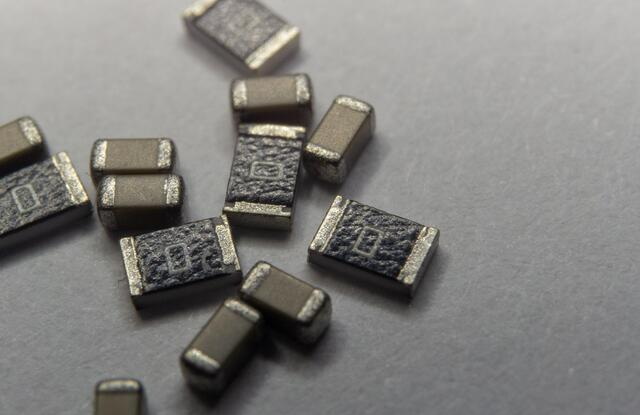

Capacitors

- Appearance: Usually rectangular or cylindrical; multilayer ceramic capacitors are common.

- Identification Marks: May have capacitance values printed on them; otherwise, they can be identified by their size and shape.

- Voltage Ratings: Capacitors often have voltage ratings marked on them, which are crucial for ensuring they operate within safe limits.

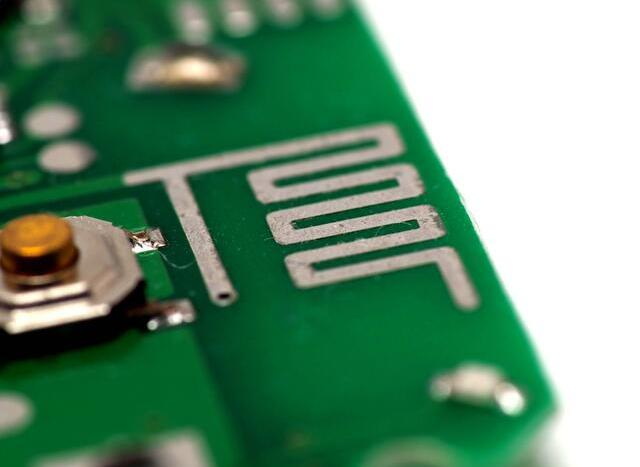

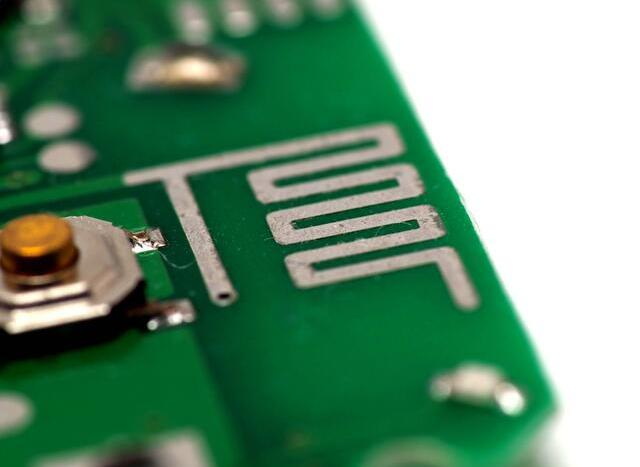

Inductors

- Appearance: Can be rectangular or cylindrical; often resemble resistors but may have a larger body.

- Identification Marks: Generally lack markings; identification relies on physical size and shape.

- Core Material: The core material can also provide clues about the inductor's characteristics, such as its inductance value and current rating.

Diodes

- Appearance: Small black packages with two terminals; can resemble transistors but have only two leads.

- Identification Marks: May have part numbers printed on them; these numbers can be cross-referenced with manufacturer specifications.

Transistors

- Appearance: Rectangular packages with three terminals; can be SOT (Small Outline Transistor) packages.

- Identification Marks: Typically marked with part numbers indicating type and specifications.

- Type Identification: Distinguishing between NPN and PNP transistors is essential for proper circuit design; this can usually be determined from the part number or datasheet.

Integrated Circuits (ICs)

- Appearance: Square or rectangular packages with multiple pins on two or four sides.

- Identification Marks: Part numbers printed on the top indicate the type and function of the IC.

- Functionality Indicators: The number of pins can also indicate the complexity and functionality of the IC; more pins typically mean more features or functions integrated into the chip.

Common Packaging Types

Different types of SMT components come in various standardized packaging formats that facilitate easy identification:

| Component Type | Common Packages |

| Resistors | 0402, 0603, 0805 |

| Capacitors | 0402, 0603, 0805 |

| Inductors | 0402, 0603 |

| Diodes | SOD-323, SOT-23 |

| Transistors | SOT-23, SOT-89 |

| Integrated Circuits | QFP, BGA, SOIC |

| LEDs | 0402, 0603 |

| Microcontrollers | TQFP, QFN |

Applications of SMT Components

SMT components are used across various applications in electronics:

- Consumer Electronics: Smartphones, tablets, laptops, televisions, and gaming consoles utilize numerous SMT components for functionality and compact design. The demand for smaller devices has driven innovation in component design and manufacturing processes.

- Industrial Equipment: Automation systems rely on reliable SMT components for control and monitoring functions. Industries such as manufacturing and logistics use these technologies to streamline operations and improve efficiency through smart devices equipped with advanced sensors and controllers.

- Automotive Electronics: Modern vehicles incorporate many SMT devices for safety systems (like airbag controls), infotainment systems (navigation and audio), engine management (fuel injection systems), and advanced driver-assistance systems (ADAS) that enhance vehicle safety and performance.

- Medical Devices: In healthcare technology, compactness is critical. Devices like portable monitors, diagnostic equipment, and implantable devices utilize SMT components to maximize functionality while minimizing size.

Challenges in Identifying SMT Components

While identifying SMT components may seem straightforward, several challenges can arise:

1. Size Variability: With the trend towards miniaturization, many components may appear similar due to their small sizes. This can lead to confusion during identification unless specific characteristics are noted carefully.

2. Lack of Markings: Some passive components may not have visible markings due to their small size or manufacturing processes that omit labeling altogether. This necessitates reliance on physical measurements or reference materials for accurate identification.

3. Counterfeit Components: The rise of counterfeit electronic parts poses significant risks in terms of reliability and safety. Identifying genuine parts requires careful scrutiny of markings against manufacturer specifications as well as sourcing from reputable suppliers.

4. Complexity of ICs: Integrated circuits can contain thousands of transistors within a single package; identifying their function often requires access to detailed datasheets that explain pin configurations and operational parameters.

Best Practices for Working with SMT Components

To effectively work with SMT components:

- Use magnification tools when inspecting small parts to ensure accurate identification.

- Maintain an organized workspace with labeled storage solutions for different component types.

- Utilize reference guides or databases that provide visual aids along with specifications for common SMT components.

- Invest in quality soldering tools designed specifically for SMT work to prevent damage during assembly or repair processes.

- Stay updated on industry trends regarding new component types or changes in packaging standards as technology evolves rapidly.

Conclusion

Identifying different types of SMT components is essential for professionals in electronics design and manufacturing. By understanding the characteristics and applications of these components, you can effectively work with PCBs and ensure optimal performance in electronic devices. As technology continues to advance, staying informed about new component types and identification methods will be crucial for success in this rapidly evolving field. The ability to accurately identify these components not only enhances product quality but also contributes significantly to the overall efficiency of electronic manufacturing processes.

FAQ

1. What are the main differences between passive and active SMT components?

Passive components do not require external power to operate (e.g., resistors), while active components do (e.g., transistors).

2. How can I identify SMD resistors?

SMD resistors typically appear as small rectangular blocks with two terminals at either end; they may also have resistance values printed on them along with color codes indicating their ratings.

3. What is the significance of component packaging in SMT?

Component packaging affects how easily they can be placed on PCBs during manufacturing; standardized packages ensure compatibility with automated assembly processes while also influencing thermal performance and reliability.

4. Are there any specific tools needed to identify SMT components?

While visual inspection is often sufficient, magnifying tools or microscopes can help identify smaller components more clearly; multimeters can also assist in testing component values when necessary.

5. Can I use through-hole components instead of SMT ones?

While it is possible to use through-hole components in some designs, they take up more space and may not provide the same performance benefits as SMT components due to their larger footprint on PCBs.

Citations:

[1] https://www.pcbonline.com/blog/pcb-smt-components.html

[2] https://vectorbluehub.com/smd-components-a-look-at-different-types-and-how-to-identify-them

[3] https://www.wevolver.com/article/smd-components

[4] https://flexipcb.com/assembly/surface-mount-components/

[5] https://www.ultralibrarian.com/2024/01/25/smt-components-size-chart-what-to-know-ulc

[6] https://www.pcbonline.com/blog/how-to-identify-smd-components.html

[7] https://www.electronicsandyou.com/blog/smd-surface-mount-electronic-components-for-smt.html

[8] https://www.tutorialsweb.com/smt/smd-components/index.htm

[9] https://www.hayawin.com/resources/types-of-smd-components-list-65221cfc2994a.html

[10] https://www.electronics-notes.com/articles/electronic_components/surface-mount-technology-smd-smt/packages.php