Content Menu

● Understanding SMT Production Lines

● Assess Production Requirements

● Define Goals and Objectives

● Develop a Comprehensive Plan

● Equipment Selection

● Facility Setup

● Installation Process

● Testing and Calibration

● Training Personnel

● Implement Continuous Improvement Practices

● Monitor Performance Metrics

● Conclusion

● FAQ

>> 1. What is Surface Mount Technology (SMT)?

>> 2. What are the key components of an SMT production line?

>> 3. How do I determine my production requirements?

>> 4. What layout designs are commonly used in SMT lines?

>> 5. Why is personnel training important in SMT manufacturing?

● Citations:

Setting up a new Surface Mount Technology (SMT) production line is a crucial step for any electronics manufacturing company. This process involves careful planning, selection of appropriate equipment, and implementation of efficient workflows. In this guide, we will discuss the essential steps to develop a comprehensive installation plan for an SMT production line.

Understanding SMT Production Lines

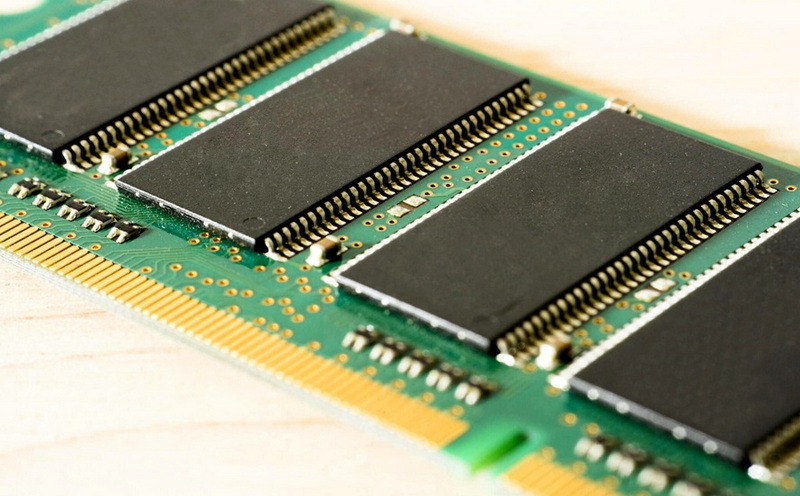

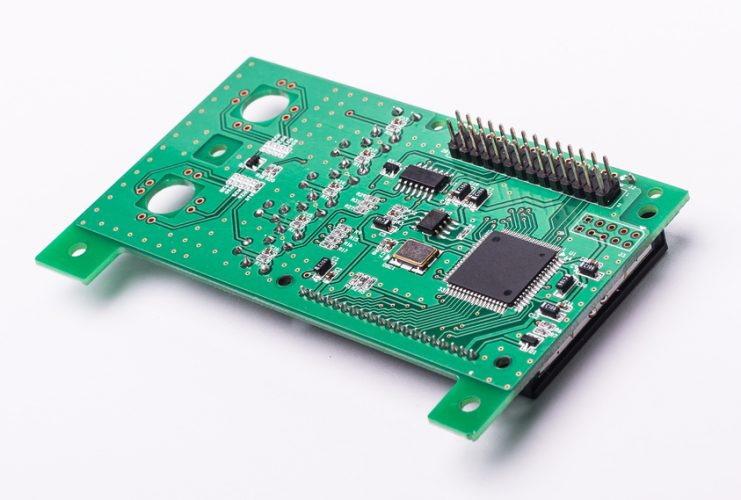

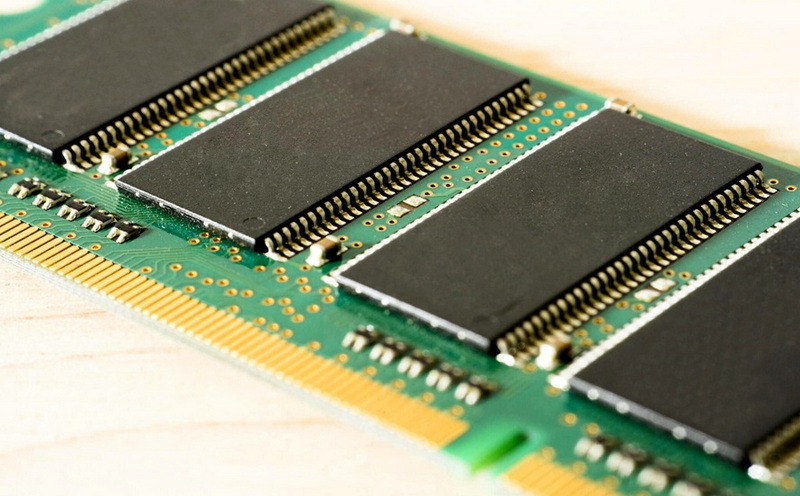

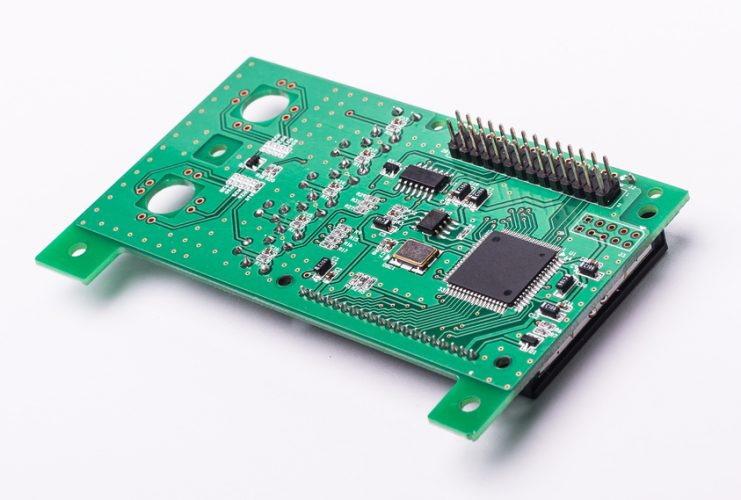

SMT is a method used to mount electronic components directly onto the surface of printed circuit boards (PCBs). The SMT production line consists of various interconnected machines that automate the assembly process, ensuring high speed and precision. Key components of an SMT line include:

- Solder Paste Printers: These machines apply solder paste to the PCB using a stencil.

- Pick-and-Place Machines: These devices place surface-mounted components onto the soldered pads on the PCB.

- Reflow Ovens: These ovens melt the solder paste to create electrical connections between the components and the PCB.

- Inspection Systems: Automated Optical Inspection (AOI) systems check for defects in component placement and soldering.

Assess Production Requirements

Before initiating the setup process, it is essential to assess your production requirements. Consider the following factors:

- Volume of Production: Determine how many units you expect to produce daily or weekly. This will influence your equipment choices and layout.

- Types of Products: Identify the types of electronic products you will manufacture. Different products may require different configurations or equipment.

- Complexity of Assemblies: Analyze the complexity of the assemblies involved. More complex assemblies may necessitate advanced equipment and additional processes.

Define Goals and Objectives

Clearly define your goals for the SMT line. Are you aiming for high-volume production, flexibility in product types, or a balance between both? Understanding your priorities will guide your decisions throughout the setup process.

Develop a Comprehensive Plan

Create a detailed plan that outlines each step of the setup process. This plan should include:

- Timelines: Establish a timeline for each phase of the project, from planning to installation and testing.

- Budget Estimates: Calculate costs associated with equipment, facility setup, and operational expenses.

- Resource Allocation: Identify resources needed for each phase, including personnel, materials, and tools.

Equipment Selection

Choosing the right equipment is critical for the efficiency and quality of your SMT line. Key considerations include:

- Pick-and-Place Machines: Select machines based on speed, accuracy, and compatibility with various component types. High-speed machines are ideal for mass production, while flexible machines can handle diverse product types.

- Solder Paste Printers: Look for printers that offer precise control over solder paste application to ensure consistent quality.

- Reflow Ovens: Choose ovens that provide uniform heating profiles to guarantee reliable solder joints. Consider features such as energy efficiency and temperature control capabilities.

Facility Setup

The physical layout of your SMT production line is vital for optimizing workflow. Consider these factors:

- Layout Design: Arrange machines in a logical sequence to minimize material handling and reduce bottlenecks. Common layouts include inline and U-shaped configurations.

- Space Requirements: Ensure sufficient space between machines for maintenance and operator access.

- Environmental Controls: Maintain appropriate temperature and humidity levels in the facility to prevent issues like solder paste contamination or component damage.

Installation Process

Once planning and equipment selection are complete, proceed with installation:

1. Install Equipment: Follow manufacturer guidelines for installing each piece of equipment. Ensure all connections are secure and that machines are aligned correctly.

2. Integrate Systems: Establish communication between different systems (e.g., pick-and-place machines, reflow ovens) to facilitate seamless operation.

3. Software Configuration: Configure software settings according to production requirements, including component libraries and placement coordinates.

Testing and Calibration

After installation, conduct thorough testing and calibration:

- Run test boards through the SMT line to verify that all equipment functions as expected.

- Inspect results focusing on component placement accuracy, solder paste application quality, and reflow profiles.

Training Personnel

Invest in training programs for operators and technicians:

- Provide comprehensive training on equipment operation, troubleshooting, and maintenance.

- Regularly update training materials to incorporate new technologies and best practices in SMT manufacturing.

Implement Continuous Improvement Practices

To ensure long-term success, implement continuous improvement practices within your SMT production line:

- Lean Manufacturing Principles: Apply lean methodologies to eliminate wasteful practices in your operation. Techniques like value stream mapping can help identify inefficiencies in workflows.

- Regular Audits: Conduct periodic audits of your processes to identify areas needing improvement or adjustment based on performance metrics.

- Feedback Mechanisms: Establish feedback loops where operators can report issues or suggest improvements based on their experiences on the floor.

Monitor Performance Metrics

Establish key performance indicators (KPIs) that align with your production goals:

- Track metrics such as cycle time, defect rates, yield rates, and overall equipment effectiveness (OEE).

- Use data analytics tools to analyze trends over time and make informed decisions about potential adjustments needed in processes or equipment.

Conclusion

Developing an installation plan for a new SMT production line requires meticulous planning, strategic decision-making regarding equipment selection, facility layout design, installation processes, testing protocols, training personnel, implementing continuous improvement practices, and monitoring performance metrics. By following these steps diligently, manufacturers can establish an efficient SMT production line that meets their operational goals while ensuring high-quality output.

FAQ

1. What is Surface Mount Technology (SMT)?

Surface Mount Technology (SMT) is an assembly method where electronic components are mounted directly onto the surface of printed circuit boards (PCBs) without needing through-holes.

2. What are the key components of an SMT production line?

Key components include solder paste printers, pick-and-place machines, reflow ovens, inspection systems (like AOI), conveyors, and cleaning machines.

3. How do I determine my production requirements?

Assess your expected volume of production, types of products being manufactured, and complexity of assemblies to define your specific needs accurately.

4. What layout designs are commonly used in SMT lines?

Common layouts include inline configurations where machines are arranged in a straight line or U-shaped layouts that provide flexibility in handling various board sizes.

5. Why is personnel training important in SMT manufacturing?

Training ensures operators are skilled in using equipment effectively, troubleshooting issues promptly, and maintaining high production quality standards.

Citations:

[1] https://www.smtfactory.com/Strategic-SMT-Production-Line-Layout-Design-id40117676.html

[2] https://www.neodensmt.com/news/improve-smt-production-efficiency-48868013.html

[3] https://www.viasion.com/blog/common-challenges-in-smt-assembly-and-solutions/

[4] https://www.raypcb.com/surface-mount-technology/

[5] https://www.smtfactory.com/Essential-Steps-for-SMT-Production-Line-Setup-id49117676.html

[6] https://www.gssmt-parts.com/what-is-the-best-layout-for-an-smt-production-line.html

[7] https://www.adoptsmt.com/en/efficiency-enhancement-in-smt-manufacturing/

[8] https://jhdpcb.com/blog/efficient-smt-assembly/

[9] https://emsginc.com/resources/the-evolution-of-surface-mount-technology/

[10] https://www.smtfactory.com/Expert-Guidance-for-SMT-Production-Line-Setup-id42117676.html

[11] https://shadowing.ai/mirror-room-question/How-do-you-handle-common-challenges-or-issues-that-may-arise-during-the-SMT-process-such-as-component-misalignment-or-br

[12] https://www.allsmt.com/SMT-line-concept-assembly-manufacturing-production-Assembly

[13] https://resources.altium.com/p/complete-guide-diy-smt-assembly-your-office

[14] https://faroads.com/start-smt-line-guide-2024/

[15] https://www.tronstol.com/how-to-optimize-smt-mounter-machine-equipment.html

[16] https://www.vse.com/blog/2022/03/15/8-common-smt-placement-issues-and-solutions/

[17] https://smt.fuji.co.jp/en/topics/2858

[18] https://wellerpcb.com/pcb-layout-guidelines-for-smt-assembly-process-limits

[19] https://mermarinc.com/2022/12/24/smt-line/

[20] https://www.smtfactory.com/Perfecting-Your-SMT-Line-Layout-for-Efficiency-id47017676.html

[21] https://www.macdermidalpha.com/sites/default/files/2021-09/ALPHA%20SMT%20Troubleshooting%20Guide%20EN%2001Jun20%20BR_0.pdf

[22] https://www.smtfactory.com/smt-production-lines.html

[23] https://www.smthelp.com/design-smt-factory-layout-smart-ems

[24] https://www.linkedin.com/pulse/essential-practices-long-lived-smt-lines-hawker-richardson

[25] https://www.raypcb.com/line-efficiency/

[26] https://www.protoexpress.com/blog/common-errors-surface-mount-technology-smt/

[27] https://www.munciepower.com/company/blog_detail/muncie_power_products_establishes_surface_mount_technology_line_offering_innovative_solutions_for_customers

[28] https://www.linkedin.com/pulse/perfect-layout-analysis-design-smt-electronics-factory-mia-feng-vxw6c

[29] https://quality-line.com/smt-quality/

[30] https://www.andwinmcpcb.com/smt-production-process-common-issues-and-their-mitigation/

[31] https://www.nbk1560.com/en/resources/mechatronics/article/SMT/

[32] https://www.smthelp.com/methods-and-measures-to-improve-the-production-efficiency-of-smt-production-line

[33] https://blogs.sw.siemens.com/valor-dfm-solutions/how-to-optimize-pcb-design-for-the-smt-assembly-process-flow/

[34] https://www.smtneoden.com/news/how-to-effectively-improve-the-production-efficiency-of-pcb-smt-machine/