Content Menu

● Understanding Semi-Automatic SMT Lines

● Key Components of a Semi-Auto SMT Line

● Factors to Consider When Choosing a Semi-Auto SMT Line

>> 1. Production Volume and Scalability

>> 2. Accuracy and Precision

>> 3. Equipment Reliability

>> 4. Ease of Use and Training Requirements

>> 5. Integration with Existing Systems

>> 6. Cost Considerations

>> 7. After-Sales Support

● Benefits of Using Semi-Auto SMT Lines

● Challenges Associated with Semi-Auto SMT Lines

● Future Trends in SMT Technology

● Conclusion

● FAQ

>> 1. What are the main components of a semi-auto SMT line?

>> 2. How does a semi-auto SMT line differ from a fully automatic one?

>> 3. What factors should I consider regarding accuracy in an SMT line?

>> 4. Why is after-sales support important when choosing an SMT line?

>> 5. What are the advantages of using a semi-auto SMT line?

In the ever-evolving landscape of electronics manufacturing, selecting the right equipment is crucial for maintaining productivity and ensuring product quality. A semi-automatic Surface Mount Technology (SMT) line can be an ideal solution for many factories looking to balance cost, efficiency, and flexibility. This article will guide you through the essential considerations when choosing a reliable semi-auto SMT line for your factory.

Understanding Semi-Automatic SMT Lines

A semi-automatic SMT line is a hybrid assembly system that combines both manual and automated processes. It typically requires some human intervention for tasks such as loading and unloading printed circuit boards (PCBs), while automating critical functions like solder paste application and component placement. This setup allows manufacturers to achieve a higher level of precision and efficiency compared to fully manual methods, while still being more cost-effective than fully automated lines.

Key Components of a Semi-Auto SMT Line

Before diving into selection criteria, it's essential to understand the basic components that make up a semi-auto SMT line:

- Stencil Printer: Used for applying solder paste onto the PCB pads accurately. Advanced models may include features like automatic alignment and cleaning systems to enhance performance.

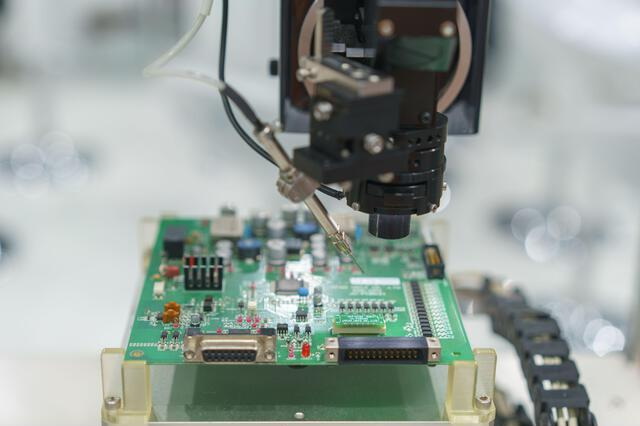

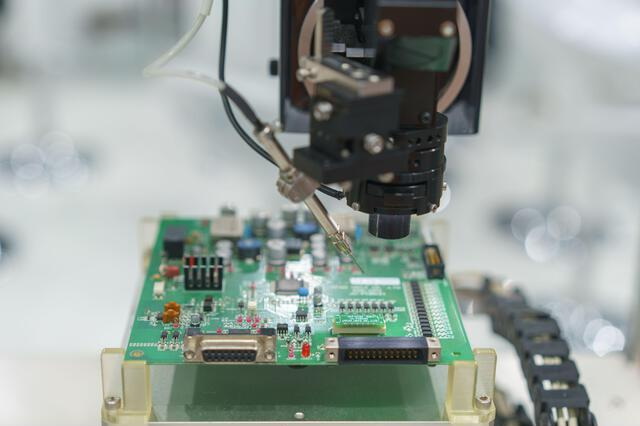

- Pick-and-Place Machine: Automates the placement of electronic components onto the PCB. The speed and accuracy of these machines are vital for maintaining production rates.

- Reflow Oven: Melts the solder paste to bond components to the PCB. Temperature profiles are crucial here; modern ovens allow for precise control over heating cycles.

- Conveyor System: Facilitates smooth movement of PCBs between different stages of production. Effective conveyor systems minimize handling time and reduce the risk of damage.

- Inspection Equipment: Ensures quality control by checking for defects in solder joints and component placement. Automated optical inspection (AOI) systems can significantly enhance defect detection rates.

Factors to Consider When Choosing a Semi-Auto SMT Line

1. Production Volume and Scalability

The first consideration is your production volume. Assess whether your current demand aligns with the capabilities of a semi-auto SMT line. If you anticipate growth, choose a system that can scale with your needs. Look for features such as adjustable settings for different PCB sizes and component types.

In addition, consider future expansion plans. A flexible SMT line can accommodate new product lines or changes in production volume without requiring significant additional investment.

2. Accuracy and Precision

Accuracy is paramount in electronics manufacturing. The ideal pick-and-place machine should have high placement accuracy (ideally around 0.0001 inches) and be capable of handling various component sizes, including smaller ones like 0402 or 0201 packages. High precision reduces defects and improves yield rates.

Moreover, consider the machine's ability to handle different types of components, including odd-form parts or those with varying heights. This versatility can be crucial in meeting diverse production requirements.

3. Equipment Reliability

Reliability directly impacts production efficiency. Research the manufacturer's reputation and customer reviews to gauge their equipment's reliability. Look for machines with robust construction, low maintenance requirements, and warranty options that provide peace of mind.

Additionally, consider the availability of spare parts and service support from the manufacturer. A reliable supplier should offer quick access to parts to minimize downtime during production runs.

4. Ease of Use and Training Requirements

Select equipment that is user-friendly to minimize training time for your staff. The complexity of operation can vary significantly between different models, so consider systems that offer intuitive interfaces or visual aids to assist operators during setup and operation.

Furthermore, look for manufacturers that provide comprehensive training programs as part of their sales package. Well-trained staff can operate machinery more efficiently and troubleshoot minor issues independently.

5. Integration with Existing Systems

Consider how well the new SMT line will integrate with your current production setup. Compatibility with existing software systems, material handling equipment, and inspection devices can streamline operations and reduce transition times.

Evaluate whether the new equipment can communicate effectively with your existing enterprise resource planning (ERP) systems or manufacturing execution systems (MES). Seamless integration can enhance data flow across your operations, improving overall efficiency.

6. Cost Considerations

While it's tempting to opt for the cheapest option, consider the total cost of ownership, including maintenance, consumables, and potential downtime costs due to equipment failure. Investing in higher-quality machinery may yield better long-term savings through increased efficiency and reduced defect rates.

Moreover, analyze financing options available from suppliers or third-party financing institutions that may help spread out costs while allowing you to invest in higher-quality equipment upfront.

7. After-Sales Support

Evaluate the level of after-sales support offered by the manufacturer or supplier. Reliable technical support can help resolve issues quickly, minimizing downtime during production runs. Ensure that training, maintenance services, and spare parts availability are part of their offerings.

Additionally, inquire about remote support capabilities or online resources such as user forums or troubleshooting guides that can assist your team in addressing common issues without waiting for on-site assistance.

Benefits of Using Semi-Auto SMT Lines

- Cost Efficiency: Semi-auto lines typically require lower initial investment compared to fully automated systems while still providing significant automation benefits.

- Flexibility: These lines can easily adapt to various production requirements without extensive reconfiguration.

- Improved Quality Control: Automated processes reduce human error in critical tasks like solder paste application and component placement.

- Reduced Labor Costs: By automating repetitive tasks, you can allocate skilled labor to more complex operations within your factory.

Challenges Associated with Semi-Auto SMT Lines

Despite their advantages, semi-auto SMT lines come with challenges:

- Dependence on Skilled Labor: While they reduce labor costs overall, these lines still require skilled operators who understand both manual processes and machine operation.

- Potential Bottlenecks: If not managed properly, manual loading/unloading processes could create bottlenecks in production flow.

- Maintenance Requirements: While generally reliable, regular maintenance is necessary to ensure optimal performance; neglecting this could lead to increased downtime.

Future Trends in SMT Technology

As technology evolves, so do SMT lines:

- Increased Automation: Even within semi-auto setups, more functions are becoming automated through advancements in robotics.

- Smart Manufacturing: The integration of IoT devices allows real-time monitoring of machine performance and predictive maintenance capabilities.

- Sustainability Focus: Manufacturers are increasingly looking at energy-efficient machines that reduce waste during production processes.

Conclusion

Choosing a reliable semi-auto SMT line requires careful consideration of various factors including production volume, accuracy, reliability, ease of use, integration capabilities, cost considerations, and after-sales support. By thoroughly evaluating these aspects alongside understanding both benefits and challenges associated with semi-auto lines, you will be better positioned to select an SMT line that meets your factory's needs while enhancing productivity and product quality.

FAQ

1. What are the main components of a semi-auto SMT line?

The main components include a stencil printer for solder paste application, a pick-and-place machine for component placement, a reflow oven for soldering components onto PCBs, a conveyor system for movement between stages, and inspection equipment for quality control.

2. How does a semi-auto SMT line differ from a fully automatic one?

A semi-auto SMT line requires some manual intervention (e.g., loading/unloading PCBs), whereas a fully automatic line operates without human involvement throughout the entire process.

3. What factors should I consider regarding accuracy in an SMT line?

You should look for machines with high placement accuracy (around 0.0001 inches) capable of handling small component sizes (like 0402 or 0201) to ensure high-quality yields.

4. Why is after-sales support important when choosing an SMT line?

After-sales support is crucial as it provides technical assistance during operational issues, training for staff on new equipment, maintenance services, and ensures availability of spare parts.

5. What are the advantages of using a semi-auto SMT line?

Benefits include cost efficiency due to lower initial investments compared to fully automated lines, flexibility in adapting to different production needs, improved quality control through automation, and reduced labor costs by minimizing manual tasks.