Content Menu

● Introduction to SMT Reels and Component Estimation

>> Traditional Methods

>> Advanced Technologies

>>> SMT Reel Estimators

>>> X-ray Component Counters

● Benefits of Using SMT Reel Estimators and X-ray Counters

>> Accuracy and Efficiency

>> Time Savings

>> Integration with Inventory Management

● Challenges and Future Developments

>> Emerging Technologies

● Importance of Accuracy in Component Counting

>> Role of Component Counting Machines

● Integration with Inventory Management Systems

● Case Studies and Applications

● Conclusion

● FAQ

>> 1. What is an SMT reel estimator?

>> 2. How does an X-ray component counter work?

>> 3. What are the benefits of using X-ray counters over manual counting?

>> 4. Can SMT reel estimators be used for all types of components?

>> 5. How do X-ray counters handle overlapping components?

● Citations:

Accurately estimating the number of components on SMT (Surface Mount Technology) reels is crucial for efficient inventory management and production planning in the electronics manufacturing industry. Traditional methods, such as manual counting or weight estimation, are often time-consuming and prone to errors. In recent years, advanced technologies like X-ray counters and specialized software tools have emerged to improve accuracy and efficiency. This article will explore various methods for estimating component counts on SMT reels, focusing on the use of SMT reel estimators and other advanced technologies.

Introduction to SMT Reels and Component Estimation

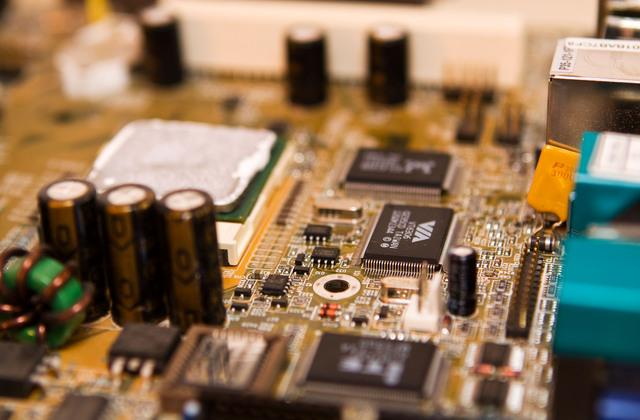

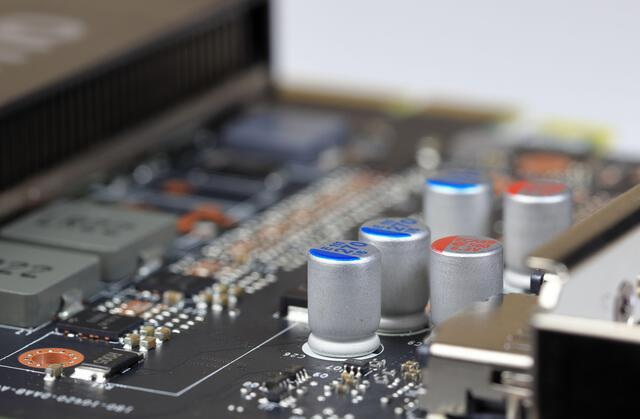

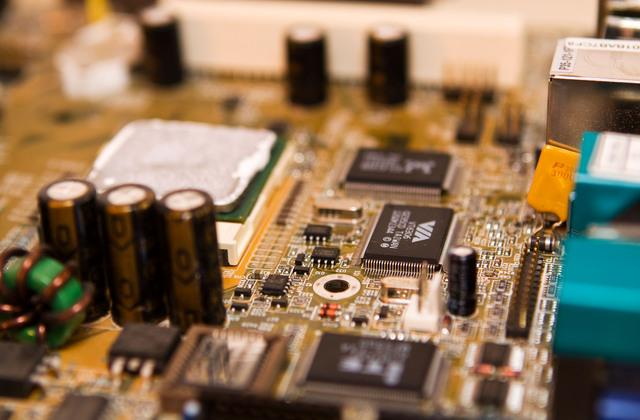

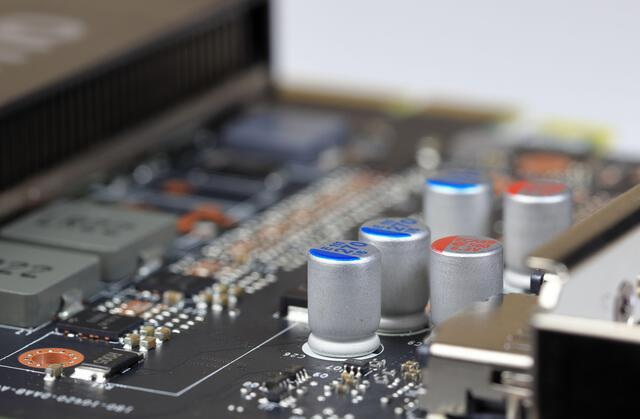

SMT reels are used to store and transport electronic components, such as resistors, capacitors, and ICs, in a compact and organized manner. These components are mounted on a tape that is wound onto a reel, making it easy to feed them into automated assembly machines. However, accurately determining the number of components remaining on a reel can be challenging, especially when the reel is partially used.

Traditional Methods

1. Manual Counting: This method involves manually unwinding the tape and counting each component. It is time-consuming and prone to human error, making it less efficient for large-scale production environments.

2. Weight Estimation: This involves weighing a known quantity of components and then using the total weight of the reel to estimate the number of components. While quick, this method lacks precision and may not be suitable for all types of components due to variations in weight.

3. Machine Vision: Some systems use cameras to visually inspect and count components. This method can be accurate but requires significant setup and maintenance.

Advanced Technologies

SMT Reel Estimators

SMT reel estimators are specialized tools designed to calculate the number of components on a reel based on physical measurements. These estimators typically require the outer and inner diameters of the reel, the thickness of the tape, and the pitch (distance between components) to estimate the total length of the tape and thus the number of components.

For example, the ReelEstim app is a user-friendly tool that allows users to input these parameters and obtain an estimate of the remaining components on a reel. It supports various units of measurement and can also estimate the unwound length and area of the tape.

X-ray Component Counters

X-ray component counters are advanced machines that use X-ray technology to accurately count components on a reel. They work by scanning the reel with X-rays, creating an image that is analyzed by sophisticated algorithms to identify and count individual components. This method is highly accurate and can handle complex scenarios like overlapping components.

X-ray counters are particularly beneficial in high-volume production environments where precision and speed are critical. They can integrate with inventory management systems, providing real-time updates and enhancing operational efficiency.

Benefits of Using SMT Reel Estimators and X-ray Counters

Accuracy and Efficiency

- SMT Reel Estimators: These tools provide a more accurate estimate than manual methods by using precise physical measurements. However, their accuracy depends on the quality of the input data.

- X-ray Counters: These machines offer the highest level of accuracy by directly imaging the components, making them ideal for critical applications where precision is paramount.

Time Savings

- SMT Reel Estimators: While not as fast as X-ray counters, these estimators are quicker than manual counting methods and can be used in environments where X-ray technology is not available.

- X-ray Counters: These machines can count components in a matter of seconds, significantly reducing the time required for inventory management and production planning.

Integration with Inventory Management

Both SMT reel estimators and X-ray counters can be integrated into inventory management systems to provide real-time updates on component quantities. This integration helps in reducing inventory errors and improving operational efficiency.

Challenges and Future Developments

Despite the advancements in component counting technologies, there are still challenges to overcome:

- Cost: Advanced technologies like X-ray counters can be expensive, making them less accessible to smaller manufacturers.

- Complexity: Some components may be difficult to distinguish using X-ray technology, requiring ongoing improvements in image processing algorithms.

Future developments are likely to focus on enhancing the affordability and accessibility of these technologies, as well as improving their accuracy and adaptability to different component types.

Emerging Technologies

In addition to X-ray counters, other innovative solutions are emerging to address the challenges of component counting. For instance, handheld devices like the BeanCounter are being developed to make accurate part counts easier and more accessible. These devices allow users to pull tape through a slot, automatically counting components as they pass through, which is particularly useful for managing partial reels or creating kits with a known number of parts[5].

Another innovative approach is the SMART:count system, which not only counts components but also prints the count on the cover tape. This eliminates the need for repeated counting and enhances inventory management accuracy by ensuring that each reel is marked with its exact component count[8].

Importance of Accuracy in Component Counting

Accurate component counting is crucial for maintaining efficient production processes and optimizing inventory management. Inaccurate counts can lead to stockouts, overstocking, and costly delays in production. Advanced technologies like X-ray counters and electronic component reel counters are designed to provide precise counts, ensuring that manufacturers can meet production timelines without disruptions[6].

Role of Component Counting Machines

Component counting machines, such as those offered by Seamark, play a significant role in enhancing manufacturing processes. These machines use advanced sensors and algorithms to accurately count components, reducing the risk of human error and improving operational efficiency. By automating the counting process, manufacturers can save time and labor costs, allowing them to focus on other critical tasks[2][4].

Integration with Inventory Management Systems

The integration of component counting technologies with inventory management systems is a key factor in achieving operational efficiency. Real-time updates on component quantities enable manufacturers to make informed decisions about production planning and inventory replenishment. This integration also helps in reducing errors in stock levels, ensuring that the right components are available when needed[3][6].

Case Studies and Applications

In real-world applications, advanced component counting technologies have significantly improved production efficiency and quality control. For example, in the automotive industry, X-ray counters are used to ensure the accuracy and reliability of electronic components, which is critical for safety and performance[3]. Similarly, in consumer electronics, these counters help maintain high-quality standards by detecting defects early in the manufacturing process.

Conclusion

Accurately estimating component counts on SMT reels is essential for maintaining efficient production processes and inventory management in the electronics manufacturing industry. SMT reel estimators and X-ray counters are powerful tools that offer significant improvements over traditional methods by providing accuracy, efficiency, and integration with inventory systems. As technology continues to evolve, we can expect even more sophisticated solutions to emerge, further enhancing the precision and speed of component counting.

FAQ

1. What is an SMT reel estimator?

An SMT reel estimator is a tool or software that calculates the number of components on a reel based on physical measurements such as the reel's outer and inner diameters, tape thickness, and component pitch.

2. How does an X-ray component counter work?

An X-ray component counter uses X-ray technology to scan a reel and create an image of the components. Advanced algorithms then analyze this image to accurately count the components.

3. What are the benefits of using X-ray counters over manual counting?

X-ray counters offer higher accuracy, speed, and efficiency compared to manual counting. They can handle complex scenarios like overlapping components and integrate with inventory management systems.

4. Can SMT reel estimators be used for all types of components?

While SMT reel estimators are versatile, their accuracy may vary depending on the component type and the quality of the input data. They are generally suitable for components stored on standard tapes.

5. How do X-ray counters handle overlapping components?

X-ray counters use sophisticated algorithms that can analyze the X-ray image from multiple angles to identify and count overlapping components accurately.

Citations:

[1] https://electronics.stackexchange.com/questions/627290/how-to-estimate-the-number-of-components-on-a-tape-reel

[2] https://www.seamarkzm.com/precision-in-component-counting-machines.html

[3] https://www.gssmt-parts.com/what-are-the-common-problems-solved-by-an-smt-reel-x-ray-counter.html

[4] https://www.seamarkzm.com/how-smd-reel-counter-machines-optimize-smt-assembly.html

[5] https://hackaday.com/tag/smt-reel/

[6] https://www.seamarkzm.com/electronic-component-reel-counters-enhancing-component-management-in-manufacturing.html

[7] https://www.seamarkzm.com/the-main-reasons-for-the-inaccurate-material-count-of-the-x-ray-component-counter.html

[8] https://core-emt.com/blog/smt-news-1/smart-count-your-reels-17

[9] https://www.cognitivemarketresearch.com/articles/surface-mount-technology-smt-market-trends-and-future-opportunities

[10] https://wellmanxray.com/blog/a-basic-guide-to-x-ray-component-counter/

[11] https://www.ipc.org/system/files/technical_resource/E6&S30_02.pdf

[12] https://www.seamarkzm.com/benefits-of-using-smt-component-counters-for-assembly-line-efficiency.html

[13] https://vc-count.com/xrhcount-en/

[14] https://www.bbntimes.com/companies/why-precision-counting-matters-in-quality-control-for-medical-and-electronic-manufacturing

[15] https://www.epsprogramming.com/blog/challenges-component-packaging-assembly-line/

[16] https://smttoday.com/2024/07/29/smt-component-market-trends-and-win-sources-strategic-responses/

[17] https://www.seamarkzm.com/maintaining-and-calibrating-an-smd-reel-counter.html

[18] https://www.rbbsystems.com/blog/bid/258884/how-to-ensure-inventory-accuracy-when-manufacturing-electronics

[19] https://wellmanxray.com/it/blog/how-x-ray-component-counters-save-labor-for-counting-reel-components%EF%BC%9F/

[20] https://wellmanxray.com/nl/bloggen/the-invaluable-role-of-x-ray-in-the-smt-industry/