Content Menu

● Introduction to SMT Stencil Printing

>> Key Components of SMT Stencil Printing

● Factors Affecting Solder Paste Quality

● Impact of Solder Paste on Printing Quality

● Role of SMT Stencil Printer in Quality Control

● Advanced Stencil Technologies

● Common Defects in Solder Paste Printing

● Environmental Impact on Solder Paste

● Conclusion

● FAQs

>> 1. What is the optimal viscosity range for solder paste in SMT stencil printing?

>> 2. How does particle size affect solder paste printability?

>> 3. What is the role of the thixotropic index in solder paste?

>> 4. How does environmental temperature affect solder paste viscosity?

>> 5. Why is regular cleaning of the SMT stencil important?

● Citations:

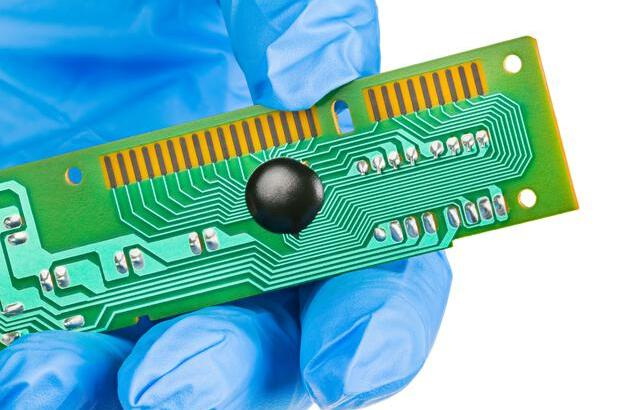

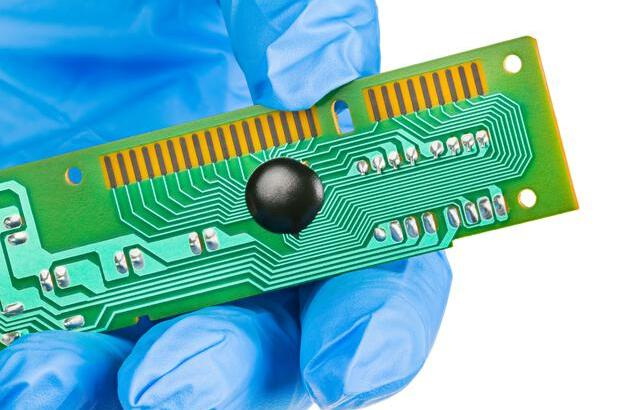

The quality of solder paste plays a crucial role in the Surface Mount Technology (SMT) stencil printing process. SMT is a widely used method for assembling electronic components onto printed circuit boards (PCBs), and solder paste printing is the initial step in this process. The solder paste is applied to the PCB pads through a stencil, which acts as a template to ensure accurate deposition of the paste. The quality of the solder paste directly impacts the printing quality, affecting the final assembly's reliability and performance.

Introduction to SMT Stencil Printing

SMT stencil printing involves applying solder paste onto PCB pads using a stencil. This process requires precise control over various factors, including the solder paste's properties, stencil design, and printing parameters. The solder paste consists of metal alloy powder and flux, which facilitate the formation of strong electrical connections during the reflow process.

Key Components of SMT Stencil Printing

1. Solder Paste: The quality of the solder paste is critical. It must have the right viscosity, particle size, and metal content to ensure smooth printing and reliable solder joints. Viscosity affects how easily the paste flows through stencil apertures, while particle size influences the paste's ability to fill small apertures.

2. Stencil: The stencil's thickness and aperture design determine the amount of solder paste deposited onto the PCB. A well-designed stencil ensures that the correct amount of paste is applied, preventing defects like bridging or insufficient solder.

3. Printing Equipment: The SMT stencil printer's precision and settings, such as squeegee speed and pressure, significantly impact the printing quality. Incorrect settings can lead to defects like uneven paste distribution or insufficient filling of stencil apertures.

Factors Affecting Solder Paste Quality

Several factors affect the quality of solder paste and its impact on SMT stencil printing:

- Viscosity: High viscosity can lead to incomplete filling of stencil apertures, while low viscosity may cause paste collapse or bridging. The optimal viscosity range is typically between 150,000 to 200,000 centipoise. Changes in ambient temperature can alter the viscosity of solder paste, necessitating adjustments in the printing environment to maintain consistency[1][5].

- Particle Size: Smaller particles improve printability, especially for high-density components, but may increase the risk of oxidation and slump.

- Thixotropic Index: This measures how the paste's viscosity changes under stress. A suitable thixotropic index ensures that the paste flows well during printing but maintains its shape afterward.

- Metal Content: The proportion of metal alloy in the paste affects its viscosity and soldering performance. Higher metal content is often preferred for stencil printing to minimize slump.

Impact of Solder Paste on Printing Quality

The quality of the solder paste directly influences the printing outcome:

- Defect Prevention: Proper solder paste quality helps prevent common defects such as solder bridging, insufficient solder, and solder balls. These defects can lead to electrical shorts or open circuits, significantly impacting the PCB's functionality.

- Process Optimization: Understanding how solder paste properties affect printing allows for optimization of the SMT process. This includes adjusting printing parameters like squeegee speed and pressure to match the paste's viscosity and particle size.

- Environmental Considerations: Temperature and humidity levels can alter the solder paste's viscosity and stability. Maintaining a controlled environment ensures consistent printing results. The optimal room temperature should be between 20-25°C, with humidity levels controlled to prevent moisture absorption or solvent evaporation[5].

Role of SMT Stencil Printer in Quality Control

The SMT stencil printer plays a crucial role in ensuring the quality of solder paste printing:

- Precision and Control: Modern SMT stencil printers offer precise control over printing parameters, allowing for adjustments to be made based on the solder paste's properties. This includes setting optimal squeegee speeds and pressures to achieve consistent paste deposition.

- Stencil Alignment: The printer's ability to accurately align the stencil with the PCB pads is vital for preventing defects like misaligned or insufficient solder paste.

- Maintenance and Cleaning: Regular maintenance and cleaning of the printer and stencil are essential to prevent solder paste residue from affecting print quality. The cleaning method should be determined based on the solder paste, stencil material, thickness, and aperture size.

Advanced Stencil Technologies

Recent advancements in stencil technologies have further enhanced the SMT printing process:

- Step Stencil Technologies: These allow for varying paste volumes across different components on the same PCB, such as QFNs and edge connectors. Techniques like laser welding and micro-machining are used to create step stencils with precise thickness control[7].

- CVD Surface Treatment: Chemical Vapor Deposition (CVD) treatments improve stencil surface smoothness and corrosion resistance, enhancing paste transfer efficiency. This is particularly beneficial for high-volume builds, as it reduces defects and improves stencil durability[2].

Common Defects in Solder Paste Printing

Several common defects can occur during the solder paste printing process:

- Insufficient Paste Deposition: This occurs when not enough solder paste is deposited on the PCB pad, leading to poor adhesion between the component and the PCB. Adjusting squeegee pressure can help increase paste deposit volume[3].

- Excess Paste Deposition: Over-application of solder paste can result in bridging or shorting issues. Optimizing squeegee speed and blade angle can minimize this defect[3].

- Misalignment: Improper placement of solder paste on the PCB pad can degrade component alignment, affecting connection quality. Automated machines with vision systems can ensure alignment accuracy[3].

- Stringing or Stenciling: This defect involves the formation of long or non-uniform lines of paste, often due to misaligned squeegee angles or pressures. Reducing squeegee pressure and increasing stencil thickness can address this issue[3].

- Paste Contamination: Contamination can occur during various stages of assembly, leading to lower-quality surface mount assemblies. Ensuring components are clean and free from residue is crucial[3].

Environmental Impact on Solder Paste

The environment plays a significant role in solder paste printability:

- Temperature and Humidity: Changes in temperature and humidity can alter solder paste viscosity and stability. Regulating these factors is essential for consistent printing results[5].

- Paste Stability: Some solder pastes are more stable under varying environmental conditions than others. Choosing a paste that is less sensitive to temperature and humidity fluctuations can improve print quality[5].

Conclusion

In conclusion, the quality of solder paste significantly affects SMT stencil printing. Factors such as viscosity, particle size, and metal content must be carefully controlled to ensure optimal printing results. The SMT stencil printer's precision and settings also play a crucial role in achieving high-quality solder paste deposition. By understanding and optimizing these factors, manufacturers can reduce defects and improve the reliability of their PCB assemblies.

FAQs

1. What is the optimal viscosity range for solder paste in SMT stencil printing?

- The optimal viscosity range for solder paste is typically between 150,000 to 200,000 centipoise. This range ensures that the paste flows well through stencil apertures without collapsing or causing bridging.

2. How does particle size affect solder paste printability?

- Smaller particles improve the printability of solder paste, especially for high-density components. However, they may increase the risk of oxidation and slump due to their larger surface area.

3. What is the role of the thixotropic index in solder paste?

- The thixotropic index measures how the solder paste's viscosity changes under stress. A suitable thixotropic index ensures that the paste flows well during printing but maintains its shape afterward, preventing defects like slump.

4. How does environmental temperature affect solder paste viscosity?

- An increase in environmental temperature reduces the viscosity of solder paste. This can lead to easier flow but may also cause the paste to collapse or spread excessively.

5. Why is regular cleaning of the SMT stencil important?

- Regular cleaning of the SMT stencil is crucial to prevent residual solder paste from affecting print quality. It ensures that the stencil remains free from contaminants and maintains its precision over time.

Citations:

[1] https://www.linkedin.com/pulse/how-solder-paste-affects-printing-quality-adam-z-

[2] https://www.stentech.com/company/cvd-treatment-for-smt-stencils

[3] https://www.smtfactory.com/Common-solder-paste-printing-defects-and-their-solutions-id62588807.html

[4] https://arshon.com/blog/mastering-solder-paste-a-key-to-reliable-pcb-design-and-manufacturing/

[5] https://fctassembly.wordpress.com/2014/11/04/the-impacts-of-the-environment-on-the-printability-of-solder-paste/

[6] https://www.qhsmt.com/2024/10/26/introduction-to-the-smt-process-affects-the-quality-of-solder-paste-printing-the-main-reasons/

[7] https://iconnect007.com/article/108107/step-stencil-technologies-and-their-effect-on-the-smt-printing-process/108110/flex

[8] https://www.protoexpress.com/blog/common-errors-surface-mount-technology-smt/

[9] https://www.technotronix.us/pcbblog/how-does-the-solder-paste-play-a-significant-role-in-pcb-smt-assembly/

[10] https://www.ipc.org/system/files/technical_resource/E39&S05_01%20-%20Tony%20Lentz.pdf

[11] https://jlcpcb.com/blog/solder-paste-printing-for-miniature-smt-component

[12] https://fctsolder.com/wp-content/uploads/2017/08/123386-361848.smt-printing-challenges.pdf

[13] https://www.linkedin.com/pulse/common-defects-solder-paste-printing-pcb-smt-alice-wu-nwqic

[14] https://jlcpcb.com/blog/role-of-solder-paste-vs-flux

[15] https://onionlinux.com/factors-influencing-the-print-quality-of-smt-solder-paste/

[16] https://www.linkedin.com/pulse/impact-smt-printing-pcb-assembly-quality-0c0mc

[17] https://www.circuitinsight.com/pdf/Stencil_Printing_Techniques_Challenging_Heterogeneous_Assembly_Applications_smta.pdf

[18] https://www.optimatech.net/knowledge-center/PCBA-Solder-Paste-Printing-Defects.aspx

[19] https://www.protoexpress.com/kb/solder-paste/

[20] https://www.poe-pcba.com/blogs-detail/pcb-knowledge-blog/what-affects-the-quality-of-smt-solder-paste