Content Menu

● Understanding SMT Assembly Lines

● The Role of PCB Unloaders in SMT Lines

● Benefits of Using an SMT Line PCB Unloader

>> Increased Efficiency

>> Improved Accuracy

>> Reduced Labor Costs

>> Enhanced Quality Control

>> Flexibility in Handling Various PCB Types

● Key Features of an Effective PCB Unloader

● The Impact of PCB Unloaders on Production Lines

>> Case Study: A Manufacturer's Experience

● Future Trends in PCB Unloading Technology

● Challenges in Implementing PCB Unloaders

>> Initial Investment Costs

>> Technical Expertise Requirement

>> Integration with Existing Systems

>> Best Practices for Optimizing PCB Unloading Processes

● Conclusion

● FAQ

>> 1. What is a PCB unloader?

>> 2. How does a PCB unloader improve efficiency?

>> 3. Can a PCB unloader handle different sizes of PCBs?

>> 4. What features should I look for in a PCB unloader?

>> 5. How does automation affect labor costs in manufacturing?

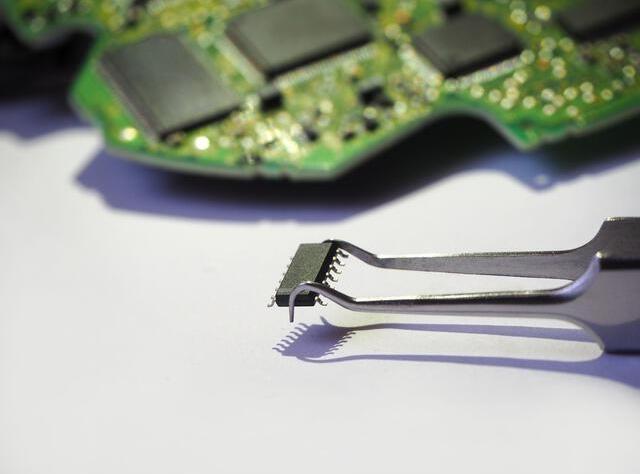

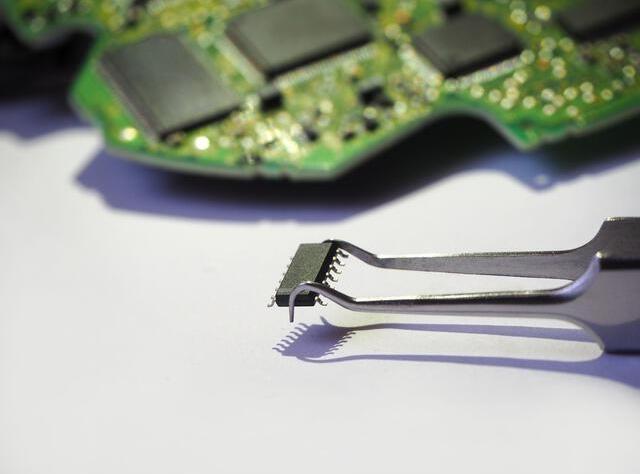

In the fast-paced world of electronics manufacturing, efficiency and precision are paramount. Surface Mount Technology (SMT) assembly lines are designed to automate the process of assembling printed circuit boards (PCBs), and one of the critical components in this automation is the PCB unloader. This article explores how an SMT line PCB unloader optimizes PCB assembly lines, enhancing productivity, reducing errors, and improving overall quality.

Understanding SMT Assembly Lines

SMT assembly lines consist of various stages, including loading, printing solder paste, placing components, reflow soldering, and unloading. Each stage is interconnected, requiring seamless transitions to maintain a continuous flow of production. The unloader plays a vital role at the end of this process by efficiently removing completed PCBs from the assembly line.

The Role of PCB Unloaders in SMT Lines

PCB unloaders are automated machines designed to extract finished PCBs from the production line and prepare them for further processing or packaging. Their primary functions include:

- Seamless Transfer: Unloaders ensure that completed PCBs are smoothly transferred from the conveyor belt to designated storage or packaging areas without manual intervention.

- Damage Prevention: By employing precise mechanisms for handling PCBs, unloaders minimize the risk of damage during the unloading process. This is crucial for maintaining product quality and reducing waste.

- Integration with Other Equipment: Modern unloaders are designed to integrate seamlessly with other components of the SMT line, such as loaders and pick-and-place machines. This integration ensures synchronized operations and maximizes throughput.

Benefits of Using an SMT Line PCB Unloader

The implementation of an SMT line PCB unloader brings several advantages that contribute to optimizing PCB assembly lines:

Increased Efficiency

Automated unloaders can operate at speeds far surpassing manual unloading methods. This increased speed translates to shorter production cycles and higher output rates. By reducing downtime associated with manual handling, manufacturers can significantly enhance their overall efficiency.

Improved Accuracy

Automated systems reduce human error associated with manual unloading. With precise control mechanisms, unloaders ensure that PCBs are correctly oriented and positioned during extraction. This accuracy is vital for maintaining consistent quality throughout the production process.

Reduced Labor Costs

By automating the unloading process, manufacturers can decrease their reliance on manual labor. This not only reduces labor costs but also allows workers to focus on more complex tasks that require human intervention, thereby optimizing resource allocation within the facility.

Enhanced Quality Control

Many modern unloaders are equipped with advanced vision systems that inspect PCBs for defects during the unloading process. These systems can detect misalignments or soldering issues before the boards proceed to packaging or further processing stages. Early detection of defects helps maintain high-quality standards and reduces rework costs.

Flexibility in Handling Various PCB Types

SMT line unloaders are designed to accommodate different sizes and types of PCBs. This versatility allows manufacturers to adapt quickly to changing production requirements without needing extensive reconfiguration of their assembly lines.

Key Features of an Effective PCB Unloader

To maximize its effectiveness, a PCB unloader should possess several key features:

- Automated Control Systems: A programmable logic controller (PLC) manages the unloader's operations, ensuring precise movements and synchronization with other machines in the SMT line.

- Vision Systems: Integrated vision systems enhance accuracy by verifying PCB orientation and detecting defects during unloading.

- User-Friendly Interfaces: Operators should be able to easily monitor and control various parameters through intuitive interfaces, simplifying machine operation and reducing training time.

- Safety Features: Safety sensors and emergency stop buttons are crucial for preventing accidents during operation, ensuring a safe working environment for personnel.

The Impact of PCB Unloaders on Production Lines

The introduction of automated PCB unloaders has revolutionized SMT assembly lines by streamlining operations and enhancing productivity. As manufacturers strive for higher output rates while maintaining quality standards, the role of unloaders becomes increasingly significant.

Case Study: A Manufacturer's Experience

Consider a mid-sized electronics manufacturer that implemented an automated PCB unloader in its SMT line. Prior to this upgrade, manual unloading resulted in frequent bottlenecks, leading to delays in production schedules. After integrating the unloader:

- Production throughput increased by 30%.

- Labor costs associated with unloading were reduced by 40%.

- The defect rate dropped significantly due to improved handling accuracy.

This case exemplifies how adopting advanced technology can yield substantial benefits in terms of efficiency and cost-effectiveness.

Future Trends in PCB Unloading Technology

As technology continues to evolve, so too will the capabilities of PCB unloaders. Future trends may include:

- Artificial Intelligence (AI) Integration: AI could enhance decision-making processes within unloaders, allowing them to adapt dynamically to variations in production conditions or product specifications.

- Enhanced Connectivity: IoT-enabled devices will allow real-time monitoring and data analysis across all machines in an SMT line, facilitating predictive maintenance and further optimizing performance.

- Sustainability Initiatives: As manufacturers focus on sustainability, future unloaders may incorporate energy-efficient technologies and materials that reduce environmental impact.

Challenges in Implementing PCB Unloaders

While there are numerous benefits associated with using automated PCB unloaders, there are also challenges that manufacturers may face during implementation:

Initial Investment Costs

The upfront costs associated with purchasing and integrating automated unloaders can be significant. Manufacturers must weigh these costs against potential long-term savings in labor and increased efficiency.

Technical Expertise Requirement

Implementing advanced technology often requires skilled personnel who can operate and maintain these systems effectively. Manufacturers may need to invest in training programs or hire specialized staff.

Integration with Existing Systems

For manufacturers with established production lines, integrating new unloaders into existing systems can pose logistical challenges. Ensuring compatibility with current machinery is essential for smooth operation.

Best Practices for Optimizing PCB Unloading Processes

To maximize the benefits of PCB unloaders while minimizing challenges, manufacturers should consider implementing best practices:

- Conduct a Thorough Assessment: Before purchasing an unloader, assess current production processes to identify specific needs and potential bottlenecks that automation could address.

- Choose Scalable Solutions: Opt for unloaders that can be easily scaled or upgraded as production demands change over time.

- Invest in Training: Provide comprehensive training for operators on how to use new equipment effectively. This investment will pay off through improved efficiency and reduced errors.

- Monitor Performance Metrics: Establish key performance indicators (KPIs) related to unloading processes. Regularly review these metrics to identify areas for improvement or optimization.

Conclusion

The integration of an SMT line PCB unloader optimizes PCB assembly lines by enhancing efficiency, improving accuracy, reducing labor costs, and ensuring high-quality output. As manufacturers continue to seek ways to streamline their operations amidst growing demand for electronic products, automated unloaders will play a crucial role in achieving these goals. By investing in advanced unloading technology and adhering to best practices for implementation and operation, companies can position themselves for success in a competitive market landscape.

FAQ

1. What is a PCB unloader?

A PCB unloader is an automated machine that extracts finished printed circuit boards from an SMT assembly line for further processing or packaging.

2. How does a PCB unloader improve efficiency?

By automating the unloading process, it eliminates manual handling time and reduces bottlenecks in production flow, leading to faster cycle times.

3. Can a PCB unloader handle different sizes of PCBs?

Yes, most modern unloaders are designed to accommodate various sizes and types of printed circuit boards.

4. What features should I look for in a PCB unloader?

Key features include automated control systems, integrated vision systems for quality inspection, user-friendly interfaces for easy operation, and safety mechanisms to protect operators.

5. How does automation affect labor costs in manufacturing?

Automation reduces reliance on manual labor for repetitive tasks like unloading PCBs, which can significantly lower labor costs while allowing workers to focus on more complex duties.