Content Menu

● Introduction to Automatic SMD Placement Machines

>> Importance of Maintenance

● Daily Maintenance Tasks

● Weekly Maintenance Tasks

● Monthly Maintenance Tasks

● Annual Maintenance Tasks

● Common Mistakes in Maintenance

● Advanced Maintenance Techniques

● Troubleshooting Common Issues

● Conclusion

● Frequently Asked Questions

>> 1. How often should I clean the nozzles of an SMD placement machine?

>> 2. What type of lubricant should be used for the moving parts of an SMD placement machine?

>> 3. How often should calibration be performed on an SMD placement machine?

>> 4. What are the consequences of inadequate maintenance on an SMD placement machine?

>> 5. How important is environmental control for SMD placement machines?

● Citations:

Maintaining an automatic SMD placement machine is crucial for ensuring its longevity and optimal performance in the production of electronic components. These machines are complex, high-tech devices that require regular maintenance to prevent breakdowns and maintain precision. In this article, we will explore the essential steps and strategies for maintaining an automatic SMD placement machine, focusing on daily, weekly, monthly, and annual maintenance tasks.

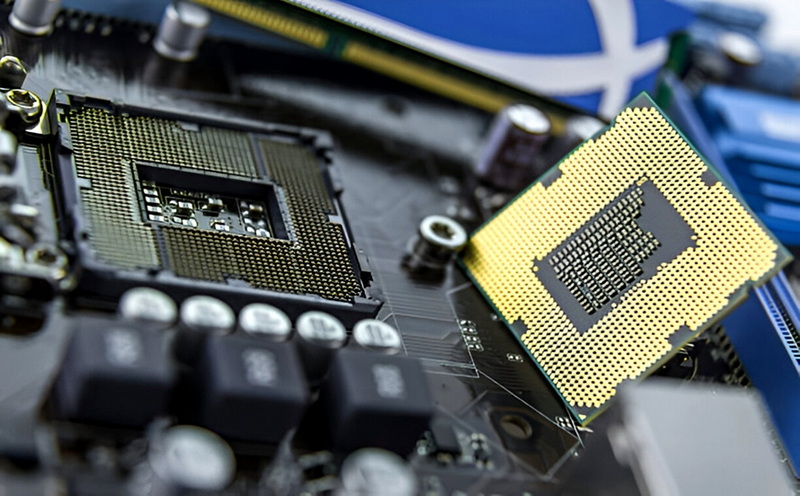

Introduction to Automatic SMD Placement Machines

Automatic SMD placement machines, also known as pick-and-place machines, are integral to the Surface Mount Technology (SMT) process. They are designed to accurately place small electronic components onto printed circuit boards (PCBs) at high speeds. The precision and reliability of these machines are critical for maintaining production quality and efficiency.

Importance of Maintenance

Regular maintenance is essential for several reasons:

- Prevents Downtime: Regular maintenance helps identify and fix issues before they cause machine failures, reducing unplanned downtime and maintaining production schedules.

- Improves Accuracy: Ensures that the machine operates with high precision, which is crucial for the quality of electronic components.

- Extends Lifespan: Proper maintenance extends the lifespan of the machine, reducing the need for premature replacements or costly repairs.

- Enhances Efficiency: Maintains the machine's performance, ensuring consistent and efficient production.

Daily Maintenance Tasks

Daily maintenance is the foundation of keeping an automatic SMD placement machine in good working condition. Here are some essential tasks:

1. Cleaning: Use a clean white cloth to wipe down the machine's surface, including the display viewer, keyboard, mouse, buttons, and switches. If necessary, use a slightly damp cloth but ensure it is wrung out to prevent water spots or damage to electronic components. Additionally, clean the dust on the surface of the SMT chip processing equipment and the track transmission sensor probe using a dust-free cloth[2].

2. Air Pressure Check: Verify that the air pressure reaches the recommended level, typically around 0.42-0.45 MPa for optimal operation[2].

3. Nozzle Inspection: Check nozzles for any blockages or wear. Clean or replace them as needed to ensure smooth operation. Regular cleaning of nozzles is crucial for maintaining high-quality production[5].

4. Feeders and Conveyors: Inspect feeders and conveyor belts for any signs of wear or misalignment. Adjust or replace them if necessary to prevent malfunctions[4].

5. Vision System Verification: Ensure that the vision system is functioning correctly to guarantee accurate component placement[7].

Weekly Maintenance Tasks

Weekly maintenance involves more in-depth checks and adjustments:

1. Lubrication: Apply lubricant to moving parts such as the XYZ axis screws and guide rails to reduce friction and prevent wear. Use the recommended lubricant for specific parts and avoid over-lubrication[1][2].

2. Component Inspection: Check for any worn or damaged components like nozzles, feeder parts, or conveyor belts. Replace them promptly to avoid downtime[4].

3. Calibration Checks: Perform quick calibration checks to ensure the machine's accuracy and alignment. Calibration is crucial for maintaining precision in component placement[1].

4. PCB Transmission Track Cleaning: Clean the PCB transmission track to remove any impurities that might affect the machine's operation[2].

5. Camera Lens Cleaning: Use a dust-free cloth to wipe the dust from the glass cover of the component identification camera[2].

Monthly Maintenance Tasks

Monthly maintenance involves more thorough cleaning and inspection:

1. Deep Cleaning: Perform a thorough cleaning of the machine's internal components, including the vacuum generator and solenoid valves. Use a vacuum cleaner to clean the dust in the distribution box and clean the equipment control board with alcohol[2].

2. Performance Tests: Conduct performance tests to evaluate the machine's accuracy and identify any potential issues. This includes checking the X-axis, Y-axis, and Z-axis lubricating oil and injecting new lubricant as needed[2][7].

3. Maintenance Logs: Review maintenance logs to identify patterns or areas needing more frequent attention. Adjust the maintenance schedule accordingly to optimize machine performance[7].

Annual Maintenance Tasks

Annual maintenance is critical for addressing deeper issues and ensuring the machine remains in optimal condition:

1. Comprehensive Inspection: Conduct a comprehensive inspection of all components, including electrical parts, to identify any signs of wear or aging. This includes checking feeders, nozzles, placement heads, spindles, and rails for wear[4].

2. Professional Maintenance: If the machine is out of warranty or has been in operation for a long time, consider hiring a professional for a thorough maintenance check. This ensures that any complex issues are addressed by experts[7].

3. Training and Updates: Ensure operators are trained on the latest maintenance procedures and any software updates. This helps maintain efficiency and prevents errors due to outdated knowledge[7].

Common Mistakes in Maintenance

Avoiding common mistakes is crucial for effective maintenance:

- Inadequate Cleaning: Regularly clean the machine to prevent dust buildup, which can cause overheating or malfunction[2].

- Insufficient Lubrication: Ensure moving parts are properly lubricated to prevent wear[1].

- Incorrect Settings: Follow manufacturer guidelines for settings to avoid poor production outcomes[3].

- Irregular Maintenance: Establish a regular maintenance schedule to catch issues early[7].

- Lack of Training: Ensure operators are well-trained in maintenance procedures to prevent errors[7].

Advanced Maintenance Techniques

In addition to routine maintenance, incorporating advanced techniques can further enhance machine performance:

- Predictive Maintenance: Use data analytics to predict potential failures before they occur. This involves monitoring machine performance metrics and scheduling maintenance based on predictive models[4].

- Automated Diagnostic Tools: Utilize automated diagnostic tools provided by some machines to identify issues quickly and efficiently. These tools can alert operators to problems such as incorrect nozzle pressure or feeder misalignment[5].

- Environmental Control: Maintain a clean, dry environment to prevent dust buildup and ensure the machine operates smoothly. Temperature and humidity control are also important for maintaining component quality[7].

Troubleshooting Common Issues

Troubleshooting common issues promptly is essential for minimizing downtime:

1. Component Placement Errors: Check for incorrect calibration, damaged feeders, or inadequate maintenance. Ensure the machine is correctly calibrated and promptly replace any damaged feeders[3].

2. Component Damage: Address issues such as malfunctioning machines, overworked conditions, or poor-quality components. Regular maintenance and proper operation can mitigate these problems[3].

3. Fiducial Recognition Issues: Ensure the camera lens is clean and perform regular calibration checks. Malfunctioning fiducial recognition software should be serviced promptly[3].

4. Pick-up and Release Issues: Check for inadequate vacuum or nozzle pressure and replace worn-out nozzles. Verify the vibration process for accuracy[3].

Conclusion

Maintaining an automatic SMD placement machine requires a structured approach that includes daily, weekly, monthly, and annual tasks. By following these guidelines and avoiding common mistakes, you can ensure the longevity and optimal performance of your machine, thereby maintaining high production quality and efficiency.

Frequently Asked Questions

1. How often should I clean the nozzles of an SMD placement machine?

- Nozzles should be cleaned daily to ensure they are free from debris and functioning smoothly. Regular cleaning prevents blockages and maintains precision.

2. What type of lubricant should be used for the moving parts of an SMD placement machine?

- Use the lubricant recommended by the manufacturer for specific moving parts. Avoid over-lubrication, as it can lead to residue buildup[1].

3. How often should calibration be performed on an SMD placement machine?

- Calibration should be performed weekly or monthly, depending on usage and manufacturer recommendations, to ensure the machine's accuracy and alignment[1].

4. What are the consequences of inadequate maintenance on an SMD placement machine?

- Inadequate maintenance can lead to reduced precision, increased downtime, and premature wear of components, ultimately affecting production quality and efficiency[3].

5. How important is environmental control for SMD placement machines?

- Maintaining a clean, dry environment is crucial for preventing dust buildup and ensuring the machine operates smoothly. Temperature and humidity control are also important for maintaining component quality[7].

Citations:

[1] https://www.zjyingxing.com/info/what-are-the-cleaning-and-maintenance-methods-82799641.html

[2] https://smtnet.com/news/index.cfm?fuseaction=view_news&company_id=59416&news_id=27399

[3] https://www.zjyingxing.com/info/what-are-the-common-smt-pick-and-place-machine-88387624.html

[4] https://smtnet.com/news/index.cfm?fuseaction=view_news&company_id=58069&news_id=30605

[5] https://hawkerrichardson.com.au/blog/win-with-smt-preventative-maintenance/

[6] https://www.linkedin.com/pulse/smt-placement-machine-common-fault-alarm-processing-method-jiang

[7] https://www.hct-smt.com/blog/keep-your-machines-running-smoothly--expert-tips-for-automatic-smt-mounter-pick-and-place-machine-maintenance

[8] https://asselems.com/en/best-practices-in-smt-assembly

[9] https://www.bigmateph.com/what-are-the-common-challenges-of-smt-and-how-to-overcome-it/

[10] https://www.linkedin.com/pulse/smt-placement-machine-operation-method-precautions-kiman-chen

[11] https://www.pcb-hero.com/blogs/lisas-column/surface-mount-technology-common-problems-and-solutions-for-efficient-smt-assembly

[12] https://www.youtube.com/watch?v=VRwx_jNutuk

[13] https://iconnect007.com/index.php/article/52613/smt-preventive-maintenance-stop-5-major-problems-with-pick-and-place-nozzles/52616

[14] https://www.protoexpress.com/blog/common-errors-surface-mount-technology-smt/

[15] https://www.smtfactory.com/How-to-maintain-the-equipment-of-the-Full-auto-SMT-Production-Line-id3333659.html

[16] https://www.zjyingxing.com/info/what-are-the-precautions-for-smt-machine-102506351.html

[17] https://www.vse.com/blog/2022/03/15/8-common-smt-placement-issues-and-solutions/

[18] https://smt.fuji.co.jp/en/solution/quality

[19] https://www.eevblog.com/forum/manufacture/recommendation-for-small-volume-smt-assembly/

[20] https://www.surfacemountprocess.com/surface-mount-troubleshooting-guide.html