Content Menu

● Understanding SMT Stencil Frames

● Types of SMT Stencil Frames

>> Framed SMT Stencil Frames

>>> Advantages of Framed SMT Stencil Frames

>>> Disadvantages of Framed SMT Stencil Frames

>> Frameless SMT Stencil Frames

>>> Advantages of Frameless SMT Stencil Frames

>>> Disadvantages of Frameless SMT Stencil Frames

>> Step-Up SMT Stencil Frames

>>> Advantages of Step-Up SMT Stencil Frames

>>> Disadvantages of Step-Up SMT Stencil Frames

● Key Factors to Consider When Choosing an SMT Stencil Frame

>> 1. Production Volume

>> 2. PCB Design and Complexity

>> 3. Budget Considerations

>> 4. Equipment Compatibility

>> 5. Storage and Handling Requirements

>> 6. Material and Thickness

● Detailed Comparison of Types of SMT Stencil Frames

● How to Choose the Right SMT Stencil Frame: Step-by-Step Guide

● Additional Tips for Maximizing SMT Stencil Frame Performance

● Conclusion

● FAQ

>> 1. What are the main types of SMT stencil frames?

>> 2. Which SMT stencil frame type is best for high-volume production?

>> 3. Are frameless SMT stencil frames reusable?

>> 4. How does stencil frame material affect performance?

>> 5. Can SMT stencil frames be customized?

Surface Mount Technology (SMT) stencils are indispensable tools in modern electronics manufacturing, enabling precise and consistent solder paste application on printed circuit boards (PCBs). The choice of the right SMT stencil frame is a critical factor that directly influences the quality of solder joints, production efficiency, and overall manufacturing costs. This article provides an in-depth exploration of the types of SMT stencil frames, their features, advantages and disadvantages, and practical guidance on how to select the best frame for your specific production needs.

Understanding SMT Stencil Frames

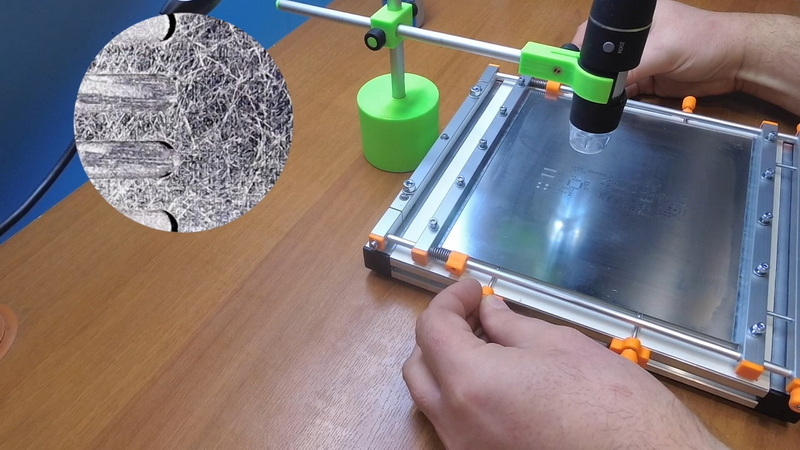

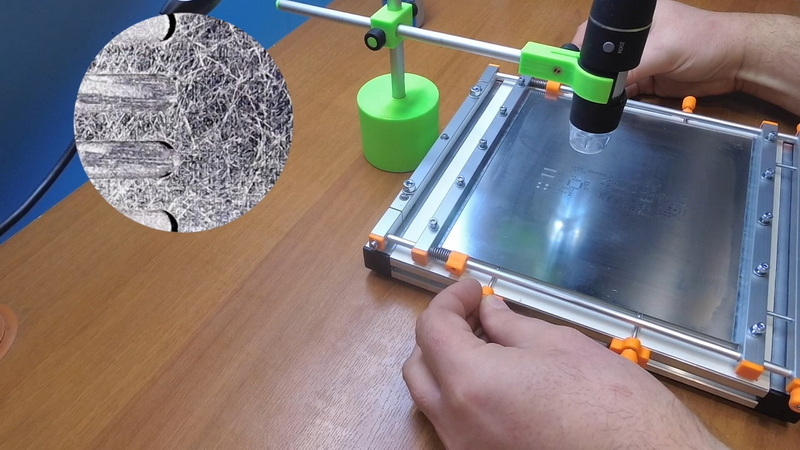

An SMT stencil frame is the supporting structure that holds the stencil sheet-a thin metal sheet with laser-cut apertures corresponding to PCB pads-in place during the solder paste printing process. The frame's primary function is to keep the stencil taut and stable, preventing any distortion or misalignment that could compromise solder paste deposition accuracy.

The performance of the stencil printing process depends heavily on the frame's ability to maintain consistent tension and alignment throughout repeated cycles. Therefore, understanding the different types of SMT stencil frames and their characteristics is essential for optimizing your PCB assembly process.

Types of SMT Stencil Frames

The SMT industry mainly uses three types of stencil frames:

- Framed SMT Stencil Frames

- Frameless SMT Stencil Frames

- Step-Up SMT Stencil Frames

Each type has unique features tailored to different manufacturing scenarios.

Framed SMT Stencil Frames

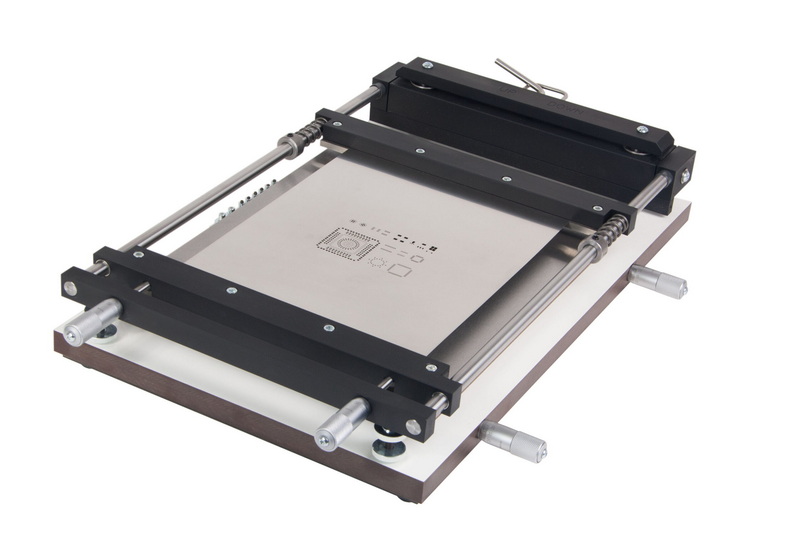

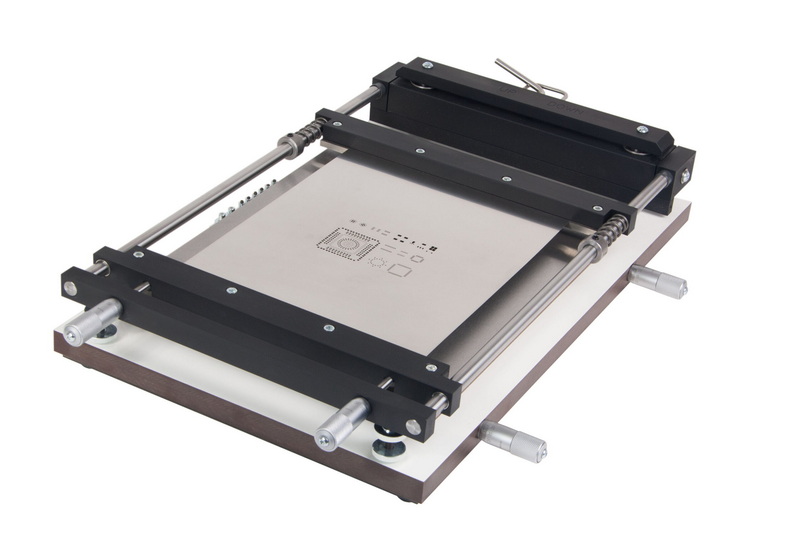

Framed SMT stencil frames consist of a laser-cut stencil sheet permanently mounted on a rigid frame, usually made of aluminum. The stencil foil is stretched tightly and affixed to the frame using adhesive or mechanical means, creating a durable and reusable unit.

Advantages of Framed SMT Stencil Frames

- Durability and Protection: The robust frame protects the delicate stencil foil from bending, warping, or damage during handling and printing, significantly extending the stencil's service life.

- Consistent Tension: The frame maintains uniform tension across the stencil, ensuring precise solder paste application, which is especially important for fine-pitch components and high-density PCBs.

- Ease of Handling: The rigid frame simplifies alignment, installation, and removal during the printing process, reducing setup time and operator error.

- Reusability: Framed stencils can be cleaned and reused multiple times, making them cost-effective for high-volume production runs.

- Compatibility: Most stencil printers and solder paste types are designed to work seamlessly with framed stencils.

Disadvantages of Framed SMT Stencil Frames

- Higher Initial Cost: The inclusion of a frame increases the upfront cost compared to frameless options.

- Storage and Shipping: Frames add bulk and weight, requiring more storage space and increasing shipping expenses.

- Size Constraints: The frame's dimensions may limit use with very small PCBs or in confined assembly environments.

Frameless SMT Stencil Frames

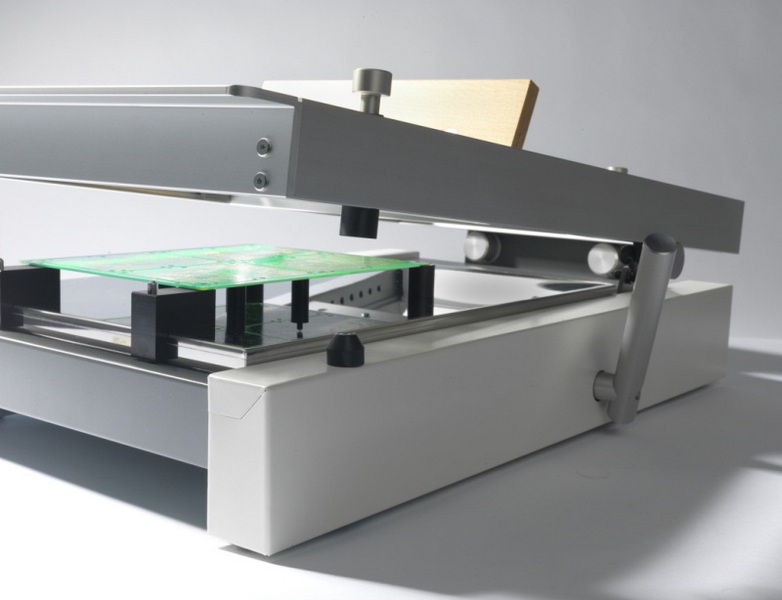

Frameless SMT stencil frames are essentially stencil sheets without a permanent frame. Instead, these sheets are tensioned and held in place by a reusable tensioning fixture or clamping system during the printing process.

Advantages of Frameless SMT Stencil Frames

- Lower Cost: Eliminating the frame reduces material and manufacturing costs, making frameless stencils attractive for budget-conscious operations.

- Compact and Lightweight: Without a bulky frame, frameless stencils are easier to store, transport, and handle in tight spaces.

- Flexibility: The lack of a rigid frame allows the stencil to be bent or curved, which can be advantageous for printing on PCBs with irregular surfaces or obstacles.

- Ideal for Prototyping: Frameless stencils are well-suited for prototype builds and low to medium volume production runs where cost and flexibility are priorities.

Disadvantages of Frameless SMT Stencil Frames

- Fragility: Without a frame, the stencil foil is more vulnerable to damage such as warping or tearing.

- Handling Challenges: Operators must exercise extra care during handling and storage to maintain stencil integrity.

- Variable Tension: The accuracy of solder paste deposition depends on the tensioning system used, which can sometimes lead to inconsistent results.

- Limited Reusability: Frameless stencils typically have a shorter lifespan and are less suited for repeated use in mass production.

Step-Up SMT Stencil Frames

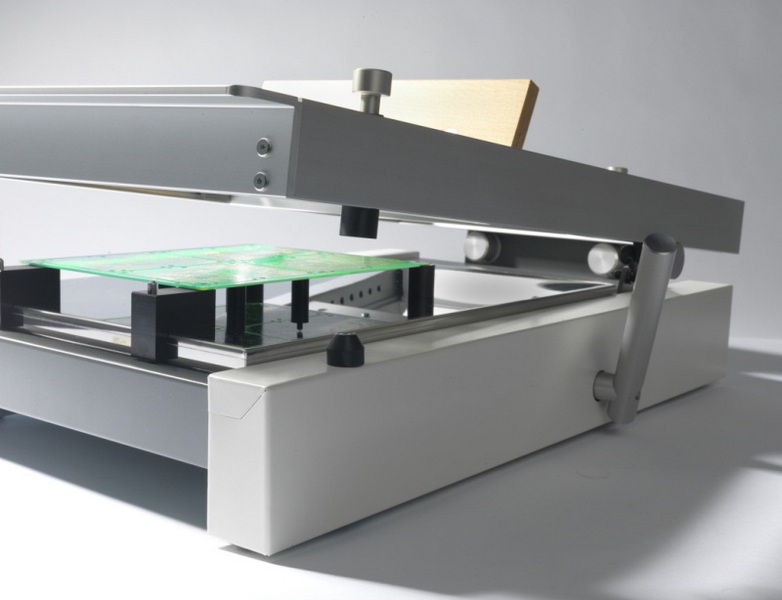

Step-up SMT stencil frames are specialized stencils designed with varying thicknesses or raised areas to accommodate components of different heights on the same PCB. These stencils are often framed but feature a unique design that allows for precise solder paste application on complex assemblies.

Advantages of Step-Up SMT Stencil Frames

- Accommodate Component Height Variations: They enable accurate paste deposition on components with varying heights, reducing bridging and tombstoning defects.

- Improved Soldering Quality: By controlling paste volume on taller or larger components, step-up stencils enhance solder joint reliability.

- Suitable for Complex Assemblies: Ideal for PCBs that combine fine-pitch and large components or have mixed technology.

Disadvantages of Step-Up SMT Stencil Frames

- Higher Cost: The complex manufacturing process and customization increase the price.

- Setup Complexity: Requires careful design and setup to ensure proper alignment and paste volume control.

- Longer Lead Times: Customization can extend production lead times.

Key Factors to Consider When Choosing an SMT Stencil Frame

Selecting the right SMT stencil frame involves evaluating several critical factors aligned with your manufacturing goals and constraints.

1. Production Volume

- High Volume Production: Framed SMT stencil frames are preferred for their durability, ease of handling, and consistent printing accuracy, making them cost-effective over time.

- Low to Medium Volume or Prototyping: Frameless stencils offer flexibility and lower upfront costs, suitable for prototype runs or small batch production.

2. PCB Design and Complexity

- Fine-Pitch Components: Framed stencils provide consistent tension and precise aperture definition, critical for fine-pitch and high-density PCB designs.

- Irregular or Small PCBs: Frameless stencils can be bent or adjusted to fit unusual board shapes or tight spaces.

- Mixed Component Heights: Step-up stencils are ideal for PCBs with components of varying heights requiring different paste volumes.

3. Budget Considerations

- Initial Investment vs. Long-Term Cost: Framed stencils require a higher initial investment but offer longer service life and lower replacement frequency.

- Cost-Sensitive Projects: Frameless stencils reduce upfront costs but may incur higher replacement expenses over time.

4. Equipment Compatibility

- Stencil Printers: Verify that your stencil printer supports the stencil frame type. Most printers accommodate framed stencils, while frameless stencils require compatible tensioning fixtures.

- Solder Paste Types: Some solder pastes may perform better with certain stencil frame setups due to tension consistency.

5. Storage and Handling Requirements

- Space Availability: Framed stencils require more storage space and careful handling to avoid damage.

- Operator Skill: Frameless stencils demand more careful handling and trained operators to maintain stencil integrity.

6. Material and Thickness

- Stencil Foil Material: Stainless steel is the industry standard due to its durability and precision.

- Frame Material: Aluminum is commonly used for frames, available in cast (solid) or extruded (hollow) forms. Cast frames offer more rigidity but are heavier, while extruded frames are lighter but less rigid.

- Stencil Thickness: Typically ranges from a few thousandths of an inch to thicker gauges, influencing solder paste volume and printing resolution.

Detailed Comparison of Types of SMT Stencil Frames

| Feature | Framed SMT Stencil Frame | Frameless SMT Stencil Frame | Step-Up SMT Stencil Frame |

| Structure | Stencil sheet permanently mounted | Stencil sheet tensioned during use | Varying thickness, usually framed |

| Cost | Higher due to frame | Lower, no frame cost | Highest due to complexity |

| Durability | High, frame protects stencil | Lower, more fragile | High, specialized design |

| Handling | Easier due to rigid frame | Requires careful handling | Similar to framed |

| Storage | Requires more space | Compact, less storage needed | Similar to framed |

| Precision | Consistent tension, high accuracy | Depends on tensioning system | Very high for complex PCBs |

| Reusability | High, suitable for mass production | Limited, better for prototypes | High, for specialized applications |

| Application | High volume, automated assembly | Low to mid volume, prototyping | Complex assemblies with varied heights |

How to Choose the Right SMT Stencil Frame: Step-by-Step Guide

1. Assess Your Production Volume: Determine whether your manufacturing process involves high-volume mass production or smaller prototype runs.

2. Evaluate PCB Complexity: Consider the component pitch, size, and layout, as well as any special requirements like mixed component heights.

3. Determine Budget Constraints: Balance your initial investment with expected stencil lifespan and replacement costs.

4. Check Equipment Compatibility: Ensure your stencil printer or tensioning system supports the frame type you plan to use.

5. Consider Storage and Handling: Plan for the space and care needed to maintain stencil condition.

6. Select Appropriate Material and Thickness: Choose stencil foil and frame materials based on durability and printing precision requirements.

7. Consult with Manufacturers: Engage with stencil suppliers to discuss customization options, lead times, and technical support.

Additional Tips for Maximizing SMT Stencil Frame Performance

- Regular Cleaning: Proper cleaning of stencils after each print cycle prevents clogging and maintains aperture integrity.

- Proper Storage: Store framed stencils in protective cases and frameless stencils flat or in tensioning fixtures to prevent warping.

- Routine Inspection: Inspect stencils for damage or wear and replace them promptly to avoid printing defects.

- Use Quality Adhesives: For framed stencils, ensure the adhesive used to mount the foil is durable and resistant to cleaning solvents.

- Optimize Stencil Thickness: Match stencil thickness to solder paste volume requirements and component specifications.

Conclusion

Choosing the right SMT stencil frame is a foundational decision that affects the entire PCB assembly process. Framed SMT stencil frames offer robust durability, consistent tension, and ease of handling, making them the go-to choice for high-volume, high-precision manufacturing. Frameless SMT stencil frames provide a flexible, cost-effective alternative for prototyping and low to medium volume production, albeit with some trade-offs in durability and handling. Step-up SMT stencil frames cater to complex PCB assemblies with components of varying heights, ensuring optimal solder paste application.

By carefully considering production volume, PCB design, budget, equipment compatibility, and handling requirements, you can select the SMT stencil frame that best aligns with your manufacturing goals. Partnering with reputable stencil manufacturers and following best practices in stencil maintenance will further enhance your production quality and efficiency.

FAQ

1. What are the main types of SMT stencil frames?

The main types are framed SMT stencil frames, frameless SMT stencil frames, and step-up SMT stencil frames. Framed stencils have a rigid frame permanently holding the stencil sheet, frameless stencils rely on tensioning systems without a permanent frame, and step-up stencils are specialized for components with varying heights.

2. Which SMT stencil frame type is best for high-volume production?

Framed SMT stencil frames are best suited for high-volume production due to their durability, consistent tension, ease of handling, and reusability.

3. Are frameless SMT stencil frames reusable?

Frameless SMT stencil sheets are generally less durable and not intended for extensive reuse. They are more suitable for prototyping or low to medium volume production.

4. How does stencil frame material affect performance?

Stencil frames are typically made from aluminum, either cast or extruded. Cast aluminum frames are solid and heavier, offering more rigidity, while extruded frames are hollow and lighter. The choice affects the frame's durability, weight, and cost.

5. Can SMT stencil frames be customized?

Yes, many manufacturers offer customization options including frame size, stencil thickness, aperture shapes, and materials to meet specific PCB assembly requirements.