Content Menu

● The Role of SMT Stencil in PCB Manufacturing

● How Improper SMT Stencil Cleaning Leads to PCB Defects

>> 1. Solder Paste Misprints

>> 2. Aperture Blockage and Solder Particle Build-Up

>> 3. Contamination Transfer to PCB

>> 4. Increased Rework and Scrap Rates

>> 5. Impact on Solder Paste Rheology and Printing Consistency

● Common Types of PCB Defects Caused by Improper SMT Stencil Wash

>> Solder Bridging

>> Insufficient Solder Volume

>> Tombstoning

>> Solder Balling

>> Open Joints

● Optimizing SMT Stencil Wash Processes

>> Manual Cleaning

>> Ultrasonic Cleaning

>> Automated Cleaning Systems

>> Dry Cleaning Methods

>> Regular Monitoring and Maintenance

● Best Practices for Effective SMT Stencil Wash

● Advanced Considerations in SMT Stencil Wash

>> Impact of Solder Paste Type on Cleaning

>> Environmental and Safety Concerns

>> Cost-Benefit Analysis of Cleaning Methods

>> Integration with Overall SMT Process

● Conclusion

● FAQ

>> 1. What is SMT stencil wash and why is it important?

>> 2. How often should SMT stencils be cleaned?

>> 3. Can manual cleaning methods effectively clean fine-pitch stencils?

>> 4. What defects can result from improper stencil cleaning?

>> 5. Are automated stencil cleaning systems better than manual cleaning?

Surface Mount Technology (SMT) stencil cleaning is a critical step in the printed circuit board (PCB) manufacturing process. The stencil acts as a precise template for depositing solder paste onto the PCB pads. If the stencil is not properly cleaned, it can lead to a range of PCB defects, impacting product quality and manufacturing efficiency. This article explores how improper SMT stencil wash causes defects, the importance of optimized cleaning processes, and best practices to ensure defect-free PCB assembly.

The Role of SMT Stencil in PCB Manufacturing

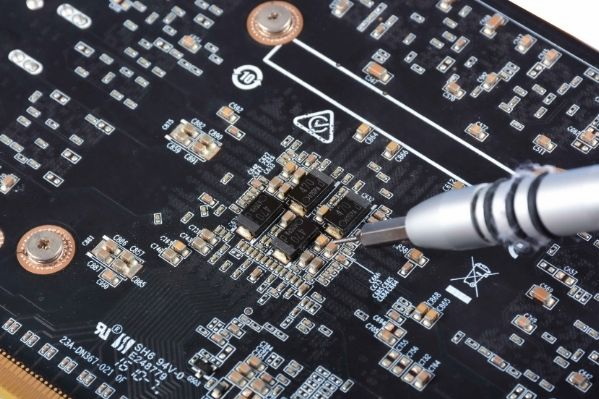

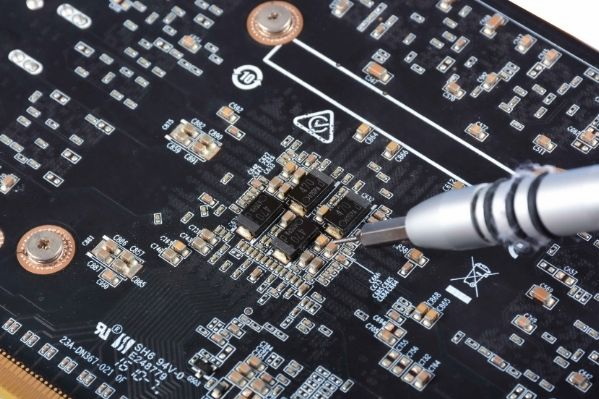

In SMT assembly, the stencil is a thin sheet, usually made of stainless steel or nickel, with apertures that correspond exactly to the PCB pads where components will be soldered. Solder paste is pressed through these apertures to deposit the exact amount of solder needed for component placement. The stencil's cleanliness directly affects solder paste volume and distribution. Any residue, dried paste, or contaminants blocking the apertures can cause insufficient or excessive solder deposition, leading to defects such as solder bridging, open joints, or tombstoning.

The stencil is arguably one of the most important tools in the SMT process. Its condition and cleanliness determine the quality of solder paste printing, which is a foundational step for successful PCB assembly. Therefore, maintaining a clean stencil through proper SMT stencil wash procedures is essential to avoid defects and ensure high yield.

How Improper SMT Stencil Cleaning Leads to PCB Defects

Improper SMT stencil cleaning can manifest in several ways that directly impact the quality of the solder paste print and, consequently, the final PCB assembly.

1. Solder Paste Misprints

When the stencil is not thoroughly cleaned, old solder paste or flux residues remain in the apertures. This contamination results in uneven solder paste transfer, causing misprints on the PCB. Misprints can manifest as insufficient solder, excess solder, or completely missing solder on pads, all of which compromise solder joint integrity.

For example, if solder paste partially clogs an aperture, the amount of paste deposited will be less than required, resulting in weak or open solder joints. Conversely, if excess solder paste accumulates around the aperture edges due to poor cleaning, it can cause bridging between pads.

2. Aperture Blockage and Solder Particle Build-Up

Dried solder particles or flux can accumulate in stencil openings if cleaning is inadequate. This blockage reduces the aperture size, causing less solder paste to be deposited than required. Narrow pitch and fine-pitch stencils are especially vulnerable, as manual cleaning may not effectively remove all contaminants.

Blocked apertures can also cause inconsistent solder paste release, leading to defects such as insufficient solder volume or misaligned deposits. This is particularly critical in modern electronics where component pitches have become extremely fine, sometimes less than 0.3 mm.

3. Contamination Transfer to PCB

Using dirty cleaning cloths or solvents can leave ionic residues on the stencil surface. These residues may dissolve into the solder paste and transfer to the PCB, potentially causing corrosion, poor solderability, or long-term reliability issues in the final product.

Ionic contamination can lead to electrochemical migration and corrosion under the component pads, which severely compromises the reliability of the PCB in harsh environments. Therefore, the choice of cleaning agents and materials used in SMT stencil wash is crucial.

4. Increased Rework and Scrap Rates

Defects caused by improper stencil cleaning lead to higher inspection failures, rework, and scrap. This not only increases production costs but also delays delivery schedules and reduces overall manufacturing efficiency.

Rework processes are time-consuming and expensive, and excessive rework can also damage PCBs or components, leading to scrap. Moreover, poor first-pass yield due to stencil-related defects can impact customer satisfaction and brand reputation.

5. Impact on Solder Paste Rheology and Printing Consistency

Residues left on the stencil can interact chemically with fresh solder paste applied during printing, altering its rheological properties. This affects paste viscosity and tackiness, leading to inconsistent printing performance and further defects.

Maintaining a clean stencil surface ensures that the solder paste maintains its intended properties, enabling consistent and repeatable solder paste prints.

Common Types of PCB Defects Caused by Improper SMT Stencil Wash

Understanding the specific defects that arise from poor stencil cleaning helps manufacturers diagnose and address root causes effectively.

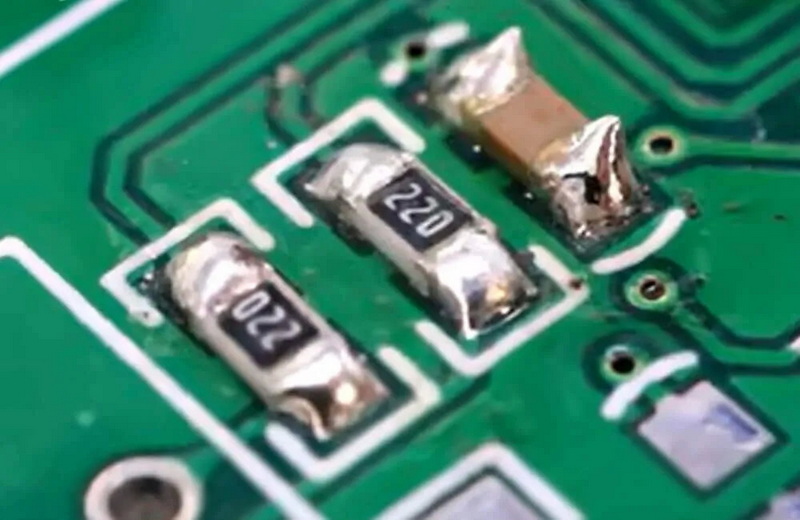

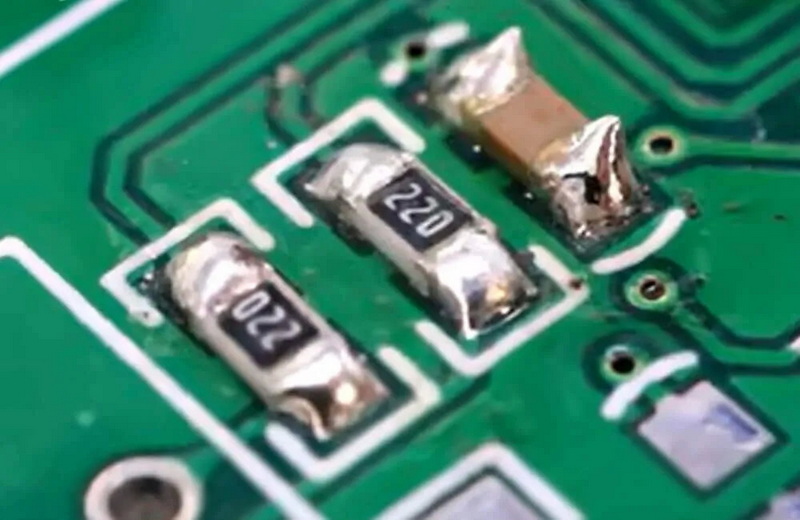

Solder Bridging

Excess solder paste deposited due to stencil contamination or aperture blockage can cause bridging between adjacent pads. This defect creates unintended electrical connections, resulting in short circuits.

Insufficient Solder Volume

Blocked apertures or partial clogging reduce the amount of solder paste deposited, leading to weak or open joints that fail to provide reliable electrical and mechanical connections.

Tombstoning

Uneven solder paste deposits caused by stencil contamination can cause small components to lift on one side during reflow, a defect known as tombstoning.

Solder Balling

Residues on the stencil can cause solder paste to spatter, creating small solder balls on the PCB surface. These balls can cause shorts or reliability issues.

Open Joints

Insufficient or missing solder paste leads to open joints where the component does not properly connect to the PCB pad.

Optimizing SMT Stencil Wash Processes

To prevent PCB defects related to stencil cleanliness, manufacturers must optimize their SMT stencil wash processes. Key considerations include:

Manual Cleaning

Manual wiping with isopropyl alcohol (IPA) or specialized stencil cleaning agents is common in low-volume production. However, this method relies heavily on operator skill and may not fully remove solder particles, especially in fine-pitch stencils.

Manual cleaning is labor-intensive and inconsistent, making it less suitable for high-volume or high-precision manufacturing. It is important to use lint-free wipes and fresh cleaning solvents to minimize contamination risks.

Ultrasonic Cleaning

Ultrasonic cleaning uses high-frequency sound waves to agitate and remove solder paste residues from stencil apertures. It is highly effective for dense and fine-pitch stencils but may cause stencil wear if used excessively.

Ultrasonic cleaning can penetrate deep into the stencil apertures, dislodging even stubborn solder particles. However, care must be taken to use appropriate cleaning solutions and cycle times to avoid damaging the stencil.

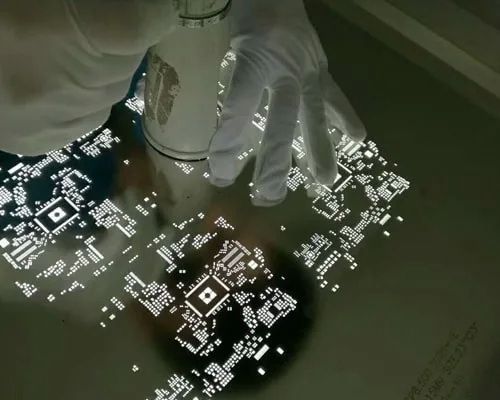

Automated Cleaning Systems

Automated wet and dry cleaning machines combine solvents, vacuum drying, and air jets to deliver consistent and repeatable cleaning results. These systems reduce operator involvement and improve uptime in high-volume production environments.

Automated systems often include programmable cleaning cycles tailored to stencil type and contamination levels. They improve throughput, reduce human error, and ensure consistent SMT stencil wash quality.

Dry Cleaning Methods

Dry cleaning techniques such as plasma cleaning or laser ablation are emerging technologies for stencil cleaning. These methods remove organic residues without the use of solvents, reducing environmental impact.

However, dry cleaning is still less common and may require specialized equipment and process development.

Regular Monitoring and Maintenance

Implementing routine stencil inspection and cleaning process monitoring ensures stencils remain free of contaminants. Using stencil cleanliness test methods can help detect residual solder paste or ionic contamination early, preventing defects downstream.

Common inspection methods include visual inspection under magnification, stencil printing tests, and ionic contamination measurement tools.

Best Practices for Effective SMT Stencil Wash

To maximize the effectiveness of SMT stencil cleaning and minimize PCB defects, manufacturers should follow these best practices:

- Use appropriate cleaning agents specifically designed for solder paste removal. Avoid harsh chemicals that can damage stencil surfaces or leave residues.

- Avoid reusing dirty cleaning cloths or solvents to prevent contamination transfer. Always use fresh, lint-free wipes and clean solvents.

- Match cleaning methods to stencil type, solder paste formulation, and production volume. For example, use ultrasonic cleaning for fine-pitch stencils and manual cleaning for simple, low-volume jobs.

- Incorporate automated cleaning for high-density, fine-pitch stencils. Automated systems ensure consistency and reduce human error.

- Schedule regular stencil maintenance and cleanliness verification. Maintain logs and inspections to track stencil condition over time.

- Train operators on proper cleaning techniques and defect identification. Skilled operators can detect early signs of stencil contamination and take corrective action.

- Optimize stencil storage conditions to prevent contamination between uses. Store stencils in clean, dry environments.

- Implement process controls to monitor solder paste printing quality. Early detection of printing defects can signal stencil cleaning issues.

- Consider stencil design improvements to facilitate cleaning. For example, using nickel-coated stencils can reduce solder paste adhesion.

Advanced Considerations in SMT Stencil Wash

Impact of Solder Paste Type on Cleaning

Different solder paste formulations (lead-free, no-clean, water-soluble) have varying cleaning requirements. No-clean pastes leave minimal residue but may still require periodic cleaning. Water-soluble pastes require more frequent cleaning due to their flux residues.

Environmental and Safety Concerns

Choosing cleaning agents with low environmental impact and ensuring proper ventilation and operator safety is essential. Many manufacturers are moving towards water-based or less toxic cleaning solutions.

Cost-Benefit Analysis of Cleaning Methods

While automated and ultrasonic cleaning systems require capital investment, their benefits in yield improvement, reduced rework, and labor savings often justify the cost. Manual cleaning may appear cheaper but can lead to higher defect rates.

Integration with Overall SMT Process

Stencil cleaning should be integrated with solder paste printing, component placement, and reflow processes to ensure overall process optimization. Data from stencil cleaning can be used to improve process controls and quality assurance.

Conclusion

Improper SMT stencil cleaning is a major cause of PCB defects, including solder paste misprints, aperture blockages, contamination transfer, and increased rework. The stencil's cleanliness directly influences solder paste deposition accuracy, which is foundational to reliable PCB assembly. Optimizing the stencil wash process through appropriate cleaning methods, regular monitoring, and maintenance is essential for achieving high-quality, reliable PCB assemblies. Investing in effective stencil cleaning not only reduces defects but also enhances production efficiency, lowers costs, and improves product reliability. As PCB designs continue to evolve with finer pitches and higher densities, the importance of proper SMT stencil wash will only grow, making it a critical focus area for electronics manufacturers.

FAQ

1. What is SMT stencil wash and why is it important?

SMT stencil wash refers to the cleaning process of the stencil used in solder paste printing during PCB assembly. It is important because a clean stencil ensures accurate solder paste deposition, preventing defects like bridging and insufficient solder joints.

2. How often should SMT stencils be cleaned?

Stencils should be cleaned regularly during production runs, especially when switching between different solder pastes or after a certain number of prints to avoid residue buildup. The frequency depends on production volume, solder paste type, and stencil aperture size.

3. Can manual cleaning methods effectively clean fine-pitch stencils?

Manual cleaning with IPA and wipes can be insufficient for fine-pitch stencils due to difficulty removing solder particles from small apertures. Ultrasonic or automated cleaning is recommended for such stencils to ensure thorough residue removal.

4. What defects can result from improper stencil cleaning?

Common defects include solder paste misprints, insufficient or excess solder deposition, solder bridging, open joints, tombstoning, solder balling, and contamination-related reliability issues.

5. Are automated stencil cleaning systems better than manual cleaning?

Automated systems provide consistent, repeatable cleaning with less operator dependency, especially beneficial in high-volume or fine-pitch stencil applications. Manual cleaning may still be suitable for low-volume or simple stencils but is generally less reliable.