Content Menu

● Introduction to HDI PCBs

>> Advantages of HDI PCBs

● Introduction to Mini SMD Machines

>> Challenges with Mini SMD Machines

● Handling High-Density PCBs with Mini SMD Machines

● Advantages of Using Mini SMD Machines for HDI PCBs

● Challenges in PCB Assembly

● Applications of HDI PCBs

● Future Trends in PCB Manufacturing

● Conclusion

● FAQs

>> 1. What are the key challenges in handling high-density PCBs with mini SMD machines?

>> 2. How can mini SMD machines be optimized for high-density PCB assembly?

>> 3. What are the advantages of using mini SMD machines for HDI PCBs?

>> 4. Are mini SMD machines suitable for large-scale production of high-density PCBs?

>> 5. How do HDI PCBs contribute to the miniaturization of electronic devices?

● Citations:

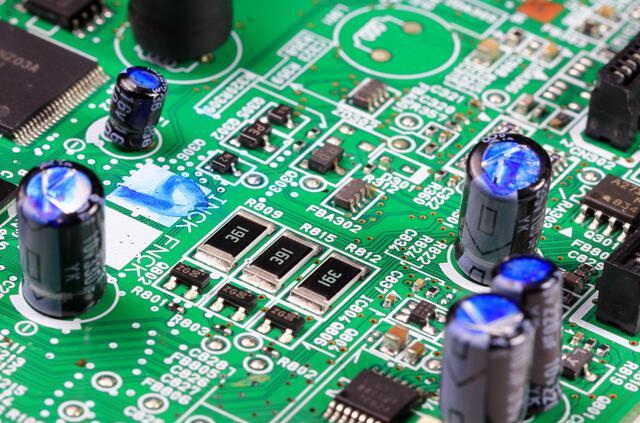

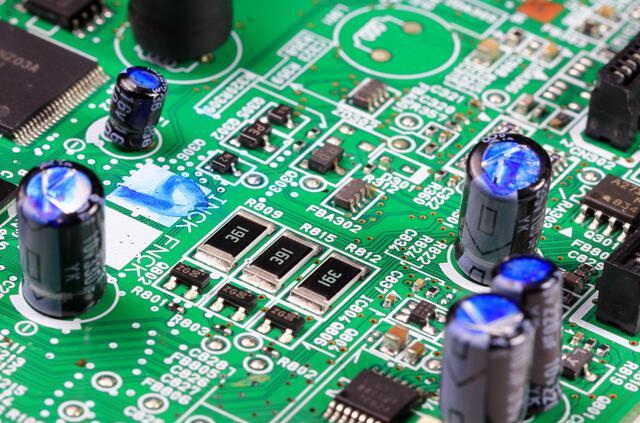

The evolution of electronic devices has led to an increased demand for compact, high-performance products. This trend is supported by advancements in High-Density Interconnect (HDI) PCBs, which enable the creation of smaller, more complex electronic devices. HDI PCBs are characterized by their ability to pack more components and connections into a smaller area, making them ideal for modern electronics like smartphones and laptops. However, handling these high-density PCBs requires specialized equipment, including Surface Mount Technology (SMT) machines. The question arises: Can a mini SMD machine effectively handle high-density PCBs?

Introduction to HDI PCBs

HDI PCBs are designed to achieve high-density interconnections by using microvias, blind vias, and buried vias. These vias are much smaller than traditional plated through-hole (PTH) vias, allowing for more components to be placed closer together. This results in PCBs that are not only smaller but also more efficient, with faster signal transmission due to reduced capacitance and inductance effects.

Advantages of HDI PCBs

- High Component Density: HDI PCBs can accommodate more components in a smaller area, making them ideal for compact devices.

- Space-Saving: The use of microvias allows for efficient use of space, reducing the overall size of the PCB.

- Fast Processing: With components placed closer together, signal transmission is faster, improving overall performance.

- Lightweight Boards: The compact design results in lighter PCBs.

- High Reliability: HDI PCBs offer high reliability due to their robust design and ability to withstand high temperatures.

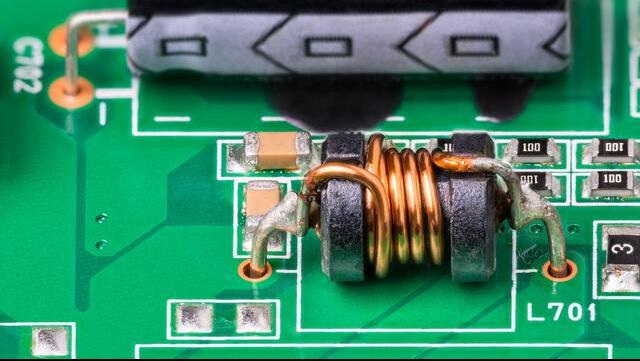

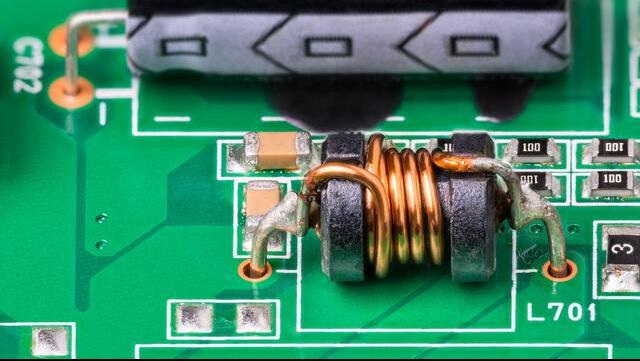

Introduction to Mini SMD Machines

Mini SMD machines are designed to handle small-scale SMT assembly tasks. These machines are compact, making them suitable for prototyping, small-batch production, or use in environments where space is limited. They typically include features like pick-and-place functionality and solder paste application, though their capabilities may be limited compared to larger industrial machines.

Challenges with Mini SMD Machines

While mini SMD machines are versatile and cost-effective for small projects, they may face challenges when dealing with high-density PCBs:

- Component Size: Handling very small components (e.g., 0201 or 01005 packages) requires precise control and specialized equipment, which may not be fully supported by mini machines.

- Accuracy and Precision: High-density PCBs demand high accuracy in component placement and soldering. Mini machines might struggle to meet these stringent requirements without advanced calibration and control systems.

- Production Volume: Mini SMD machines are generally designed for low-volume production. High-density PCBs often require larger production runs, which can be beyond the capacity of these machines.

Handling High-Density PCBs with Mini SMD Machines

To effectively handle high-density PCBs with a mini SMD machine, several factors must be considered:

1. Component Handling: Ensure the machine can accurately place small components. This might involve upgrading or calibrating the pick-and-place mechanism.

2. Solder Paste Application: Use high-quality solder paste with appropriate powder size to ensure reliable connections for small components.

3. Process Control: Implement tight process controls, such as maintaining a high capability process index (Cpk) to ensure consistent quality.

4. Design Adaptation: Optimize PCB design for mini SMD machine capabilities, possibly by simplifying component layouts or using larger components where feasible.

Advantages of Using Mini SMD Machines for HDI PCBs

Despite the challenges, mini SMD machines offer several advantages for handling high-density PCBs in certain contexts:

- Cost-Effectiveness: For small-scale or prototyping projects, mini machines can be more cost-effective than investing in large industrial equipment.

- Flexibility: They allow for quick design iterations and testing, which is beneficial in the development phase of new products.

- Space Efficiency: Mini machines are ideal for environments with limited space, such as small workshops or educational settings.

Challenges in PCB Assembly

The assembly of high-density PCBs poses several challenges, including:

- Signal Integrity: Maintaining signal integrity is crucial, especially in high-speed applications. Miniaturization increases parasitic capacitive coupling and trace crosstalk, which can distort signals[1].

- Component Placement: Precise component placement is necessary due to the densely packed nature of HDI PCBs. Minor inaccuracies can lead to electrical shorts or impaired connectivity[1].

- Solder Joint Reliability: Solder joints in high-density PCBs are prone to failure due to thermal stresses and mechanical shocks. Ensuring reliable solder joints is critical for maintaining PCB functionality[1].

Applications of HDI PCBs

HDI PCBs are widely used in various applications where compactness and high performance are essential:

- Mobile Devices: HDI PCBs are used in smartphones and tablets to enhance electrical performance and reduce size[2].

- Network Equipment: They are applied in routers and servers to ensure compact design and high-speed signal processing[7].

- Medical Devices: HDI PCBs are used in complex medical devices where space is limited but high functionality is required[5].

Future Trends in PCB Manufacturing

The future of PCB manufacturing is moving towards even higher density and miniaturization. Technologies like micro-hole drilling are becoming more prevalent, allowing for more efficient routing and reduced layer counts in HDI PCBs[4]. Additionally, advancements in SMT technology continue to improve component density and assembly efficiency, making it easier to produce compact electronic devices[3][8].

Conclusion

While mini SMD machines can be used to handle high-density PCBs, their effectiveness depends on the specific requirements of the project. For small-scale or prototyping work, these machines can be highly beneficial. However, for large-scale production or projects requiring extremely high precision and speed, larger industrial SMT machines may be more suitable. By understanding the capabilities and limitations of mini SMD machines, manufacturers can make informed decisions about their use in high-density PCB assembly.

FAQs

1. What are the key challenges in handling high-density PCBs with mini SMD machines?

Mini SMD machines face challenges such as handling very small components, maintaining high accuracy, and managing production volume limitations when dealing with high-density PCBs.

2. How can mini SMD machines be optimized for high-density PCB assembly?

Optimization involves ensuring the machine can accurately place small components, using appropriate solder paste, and implementing tight process controls.

3. What are the advantages of using mini SMD machines for HDI PCBs?

Advantages include cost-effectiveness for small projects, flexibility in design iterations, and space efficiency.

4. Are mini SMD machines suitable for large-scale production of high-density PCBs?

Generally, mini SMD machines are not suitable for large-scale production due to limitations in production volume and precision compared to industrial machines.

5. How do HDI PCBs contribute to the miniaturization of electronic devices?

HDI PCBs contribute by allowing more components to be packed into a smaller area, enabling the creation of compact devices with high functionality.

Citations:

[1] https://www.electronicdesign.com/technologies/eda/printed-circuit-boards/article/55041417/viasion-technology-top-5-miniaturization-challenges-in-pcb-assembly-and-their-solutions

[2] https://finestpcb.com/what-are-the-main-applications-of-hdi-circuit-boards/

[3] https://www.pcbjhy.com/blog/pros-and-cons-of-smt-pcb-assembly/

[4] https://rushpcb.com/micro-hole-technology-for-hdi-pcbs/

[5] https://www.mpe-electronics.co.uk/2024/01/23/future-pcb-industry-trends-to-watch-out-for

[6] https://www.protoexpress.com/blog/choosing-smaller-footprints-hdi-design/

[7] https://www.linkedin.com/pulse/hdi-pcb-types-advantages-disadvantages-applications-%E6%97%AD%E4%B8%9C-%E8%A2%81-vg97c

[8] https://www.mpe-electronics.co.uk/2024/10/22/advantages-and-disadvantages-of-surface-mount-technology

[9] https://www.linkedin.com/pulse/how-optimize-reduce-pcb-size-tiffany-zou-2dinc

[10] https://www.technotronix.us/pcbblog/top-trends-in-printed-circuit-board-manufacturing-for-2024/

[11] https://www.protoexpress.com/blog/common-errors-surface-mount-technology-smt/

[12] https://www.epectec.com/pcb/hdi-boards.html

[13] https://finestpcb.com/the-benefits-of-high-density-smt-chip-processing-for-circuit-boards/

[14] https://www.protoexpress.com/blog/becoming-a-pcb-master-hdi/

[15] https://www.pcbpower.us/blog/top-trends-pcb-assembly

[16] https://resources.altium.com/p/uhdi-pushes-pcb-feature-size-miniaturization-its-limit

[17] https://www.pcbunlimited.com/HDI-PCBs

[18] https://www.protoexpress.com/blog/good-not-so-good-sides-surface-mount-technology/

[19] https://www.creativehitech.com/blog/how-to-optimize-hdi-design-in-electronics/

[20] https://novaenginc.com/future-of-circuit-board-assembly/