Content Menu

● Understanding SMT and Its Importance

>> What is SMT?

>> The Role of Experienced Manufacturers

● Advantages of Working with Experienced SMT Line Manufacturers

>> 1. Expertise in Technology and Processes

>> 2. Advanced Equipment and Facilities

>> 3. Comprehensive Support Services

>> 4. Customization Capabilities

>> 5. Strong Industry Relationships

● The Impact of Experience on Cost Efficiency

● Conclusion

● FAQ

>> 1. What should I look for when choosing an SMT line manufacturer?

>> 2. How does working with experienced manufacturers improve product quality?

>> 3. Can experienced SMT line manufacturers handle custom projects?

>> 4. What kind of support services do experienced manufacturers provide?

>> 5. Why is automation important in SMT manufacturing?

Surface Mount Technology (SMT) has revolutionized the electronics manufacturing industry, enabling the production of compact and efficient electronic devices. As the demand for high-quality electronic components continues to rise, partnering with experienced SMT line manufacturers becomes crucial for businesses aiming to enhance their production capabilities. This article explores the numerous advantages of collaborating with seasoned SMT line manufacturers, highlighting their expertise, technology, and support services.

Understanding SMT and Its Importance

What is SMT?

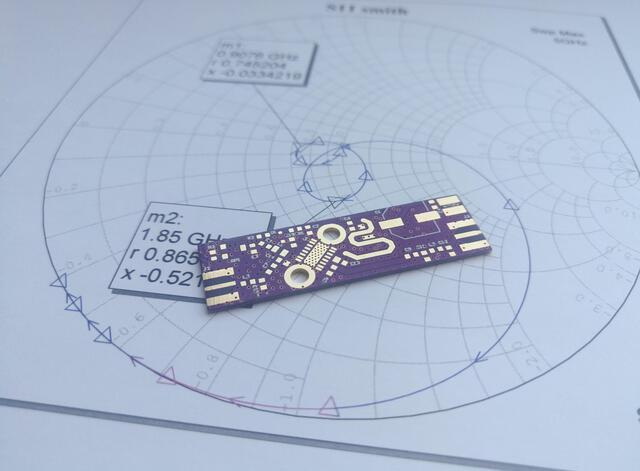

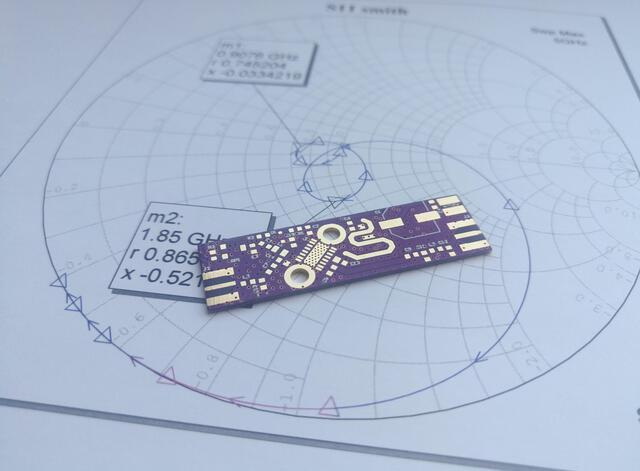

Surface Mount Technology is a method used to mount electronic components directly onto the surface of printed circuit boards (PCBs). This technique allows for a more efficient use of space and can significantly reduce the size of electronic devices. SMT has become the standard in modern electronics manufacturing due to its several benefits:

- Higher component density: SMT enables more components to be placed on a PCB compared to traditional through-hole technology.

- Improved performance: The shorter electrical paths in SMT can lead to better performance and reduced signal interference.

- Cost-effectiveness: The ability to automate the assembly process reduces labor costs and increases production speed.

The Role of Experienced Manufacturers

Experienced SMT line manufacturers are vital in ensuring that these advantages are fully realized. Their expertise not only encompasses the technical aspects of SMT but also includes a deep understanding of industry standards and customer requirements.

Advantages of Working with Experienced SMT Line Manufacturers

1. Expertise in Technology and Processes

Experienced manufacturers possess a wealth of knowledge regarding the latest technologies and processes in SMT. They stay updated with industry trends, ensuring that they can offer state-of-the-art solutions. This expertise translates into several benefits:

- Quality Assurance: Experienced manufacturers implement rigorous quality control measures, resulting in fewer defects and higher reliability of products.

- Process Optimization: They can optimize manufacturing processes, reducing cycle times and increasing throughput.

- Troubleshooting: With years of experience, these manufacturers can quickly identify and resolve issues that may arise during production.

In addition to these benefits, experienced manufacturers often have access to proprietary technologies that can enhance production efficiency. For instance, they may utilize advanced software for process simulation or predictive maintenance tools that minimize downtime by anticipating equipment failures before they occur.

2. Advanced Equipment and Facilities

Established SMT line manufacturers invest significantly in advanced equipment and facilities. This investment is crucial for maintaining high production standards. The benefits include:

- High Precision: Modern SMT machines offer superior accuracy in component placement, which is essential for complex designs.

- Scalability: Experienced manufacturers can scale their operations to meet varying production demands without compromising quality.

- Automation: Automation technologies implemented by seasoned manufacturers enhance efficiency, reduce labor costs, and minimize human error.

Moreover, these manufacturers often operate under cleanroom conditions that are essential for producing high-quality electronics. Cleanrooms help prevent contamination during assembly, which is particularly important for sensitive components that may be affected by dust or other particulates.

3. Comprehensive Support Services

Working with experienced manufacturers often means access to a range of support services that can enhance your production capabilities:

- Technical Support: They provide ongoing technical support, helping clients troubleshoot issues and optimize their processes.

- Training Programs: Many experienced manufacturers offer training programs for client staff, ensuring that they are well-equipped to handle the latest technologies.

- Supply Chain Management: Established manufacturers often have robust supply chain management systems that ensure timely delivery of materials and components.

In addition to these services, experienced manufacturers may also offer design assistance during the early stages of product development. This collaboration can help identify potential manufacturing challenges early on, allowing for design modifications that facilitate easier assembly later in the process.

4. Customization Capabilities

Every business has unique requirements when it comes to electronics manufacturing. Experienced SMT line manufacturers understand this need for customization:

- Tailored Solutions: They can design and implement customized solutions that fit specific project requirements, whether it's for small batch runs or large-scale production.

- Flexibility: These manufacturers are typically more flexible in adapting their processes to meet changing customer needs or market demands.

- Rapid Prototyping: Experienced manufacturers often have rapid prototyping capabilities, allowing businesses to test designs quickly before full-scale production.

Customization extends beyond just component placement; it includes adapting manufacturing processes to accommodate different materials or assembly techniques as required by specific projects. This flexibility is particularly valuable in industries such as automotive or medical devices, where compliance with strict regulations is necessary.

5. Strong Industry Relationships

Long-standing relationships with suppliers, customers, and industry organizations are another significant advantage offered by experienced SMT line manufacturers:

- Access to Quality Materials: Their established relationships often mean better access to high-quality materials at competitive prices.

- Networking Opportunities: Working with reputable manufacturers can open doors to networking opportunities within the industry, facilitating collaborations and partnerships.

- Regulatory Compliance: Experienced manufacturers are well-versed in industry regulations and standards, ensuring compliance throughout the manufacturing process.

These relationships also enable experienced manufacturers to stay ahead of market trends by gaining insights into emerging technologies or shifts in consumer preferences. This knowledge can be invaluable when developing new products or enhancing existing ones.

The Impact of Experience on Cost Efficiency

One might wonder how experience translates into cost efficiency when working with SMT line manufacturers. While it may seem counterintuitive at first—given that seasoned manufacturers may charge higher rates than newer companies—the long-term savings often outweigh initial costs:

- Reduced Waste: Experienced manufacturers have refined their processes over time, leading to less material waste during production. This efficiency not only saves money but also supports sustainability efforts.

- Lower Rework Rates: With stringent quality control measures in place, defects are minimized. This results in lower rework rates and associated costs.

- Faster Time-to-Market: The combination of advanced equipment and optimized processes allows experienced manufacturers to produce products more quickly. A faster time-to-market can provide a significant competitive advantage in rapidly changing industries.

Conclusion

Partnering with experienced SMT line manufacturers is essential for businesses looking to enhance their electronics manufacturing capabilities. Their expertise in technology, advanced equipment, comprehensive support services, customization capabilities, strong industry relationships, and cost efficiencies provide a competitive edge that can significantly impact product quality and operational efficiency. In a rapidly evolving market where precision and reliability are paramount, choosing an experienced partner is not just beneficial; it is imperative for success.

FAQ

1. What should I look for when choosing an SMT line manufacturer?

When selecting an SMT line manufacturer, consider their experience in the industry, technological capabilities, quality control processes, customization options, and customer support services.

2. How does working with experienced manufacturers improve product quality?

Experienced manufacturers implement stringent quality control measures throughout the production process, utilize advanced equipment for precision placement, and have established protocols for troubleshooting defects.

3. Can experienced SMT line manufacturers handle custom projects?

Yes, many experienced SMT line manufacturers offer tailored solutions designed to meet specific project requirements, including rapid prototyping for testing designs before full-scale production.

4. What kind of support services do experienced manufacturers provide?

Experienced manufacturers typically offer technical support, training programs for client staff, supply chain management assistance, and ongoing consultation throughout the production process.

5. Why is automation important in SMT manufacturing?

Automation enhances efficiency by reducing labor costs and minimizing human error while increasing production speed and consistency in component placement accuracy.