Content Menu

● Understanding Surface Mount Technology (SMT)

>> The Role of Surface Mount Device Tape

● Advantages of Using Surface Mount Device Tape

>> Enhanced Precision

>> Increased Efficiency

>> Improved Component Protection

>> Versatility

>> Cost-Effectiveness

● Applications of Surface Mount Device Tape

>> Consumer Electronics

>> Automotive Electronics

>> Medical Devices

>> Industrial Equipment

>> Telecommunications

● Conclusion

● Related Questions

>> 1. What is the difference between SMT and SMD?

>> 2. How does SMD tape improve manufacturing efficiency?

>> 3. Can SMD tape be used for all types of electronic components?

>> 4. What are the key benefits of using SMT in electronics manufacturing?

>> 5. How does SMD tape protect components during assembly?

Surface Mount Device (SMD) tape plays a crucial role in the electronics manufacturing industry, particularly in the assembly of printed circuit boards (PCBs). This article explores the significance of SMD tape, its advantages, and its applications in modern electronics manufacturing.

Understanding Surface Mount Technology (SMT)

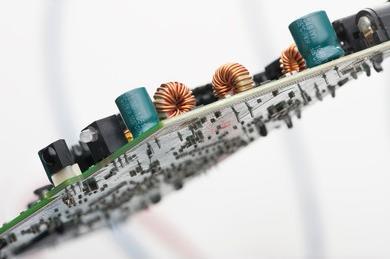

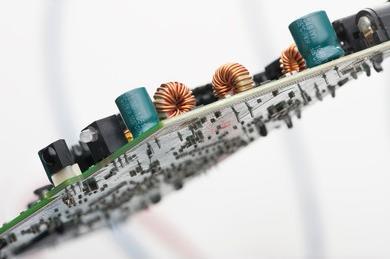

Surface Mount Technology (SMT) is a method that allows electronic components to be mounted directly onto the surface of PCBs. Unlike traditional through-hole technology, where components are inserted into holes in the PCB, SMT enables a more compact design, allowing for smaller and lighter electronic devices. The components used in SMT are known as Surface Mount Devices (SMDs), which include resistors, capacitors, and integrated circuits.

The Role of Surface Mount Device Tape

SMD tape is a specialized adhesive tape used to hold SMDs in place during the assembly process. It is designed to facilitate the automated placement of components onto PCBs, ensuring precision and efficiency. The tape typically consists of a carrier material, such as plastic or paper, with adhesive properties that securely hold the components while allowing for easy removal during the soldering process.

Advantages of Using Surface Mount Device Tape

Enhanced Precision

One of the primary benefits of using SMD tape is the enhanced precision it offers during the assembly process. The tape ensures that components are accurately positioned on the PCB, reducing the risk of misalignment and improving the overall quality of the final product.

Increased Efficiency

SMD tape significantly increases the efficiency of the manufacturing process. Automated pick-and-place machines can quickly and accurately place components onto the PCB, minimizing the time required for manual assembly. This efficiency translates to lower production costs and faster turnaround times.

Improved Component Protection

SMD tape provides a protective layer for components during handling and transportation. This protection is essential in preventing damage to sensitive electronic parts, ensuring that they arrive at the assembly line in optimal condition.

Versatility

SMD tape is versatile and can accommodate a wide range of component sizes and shapes. This adaptability makes it suitable for various applications, from consumer electronics to industrial machinery.

Cost-Effectiveness

Using SMD tape can lead to significant cost savings in the manufacturing process. By streamlining assembly and reducing the likelihood of defects, manufacturers can lower their overall production costs while maintaining high-quality standards.

Applications of Surface Mount Device Tape

SMD tape is widely used in various sectors of the electronics industry, including:

Consumer Electronics

In the consumer electronics sector, SMD tape is essential for assembling devices such as smartphones, tablets, and laptops. The compact design of these devices relies heavily on SMT and SMDs, making SMD tape a critical component in their production.

Automotive Electronics

The automotive industry increasingly relies on electronic components for various functions, from engine control units to infotainment systems. SMD tape ensures that these components are securely mounted and properly aligned, contributing to the reliability and safety of automotive electronics.

Medical Devices

In the medical field, precision and reliability are paramount. SMD tape is used in the assembly of medical devices, ensuring that components are accurately placed and securely held, which is crucial for the performance of life-saving equipment.

Industrial Equipment

Industrial machinery often incorporates complex electronic systems that require precise assembly. SMD tape facilitates the efficient and accurate placement of components in these systems, enhancing their functionality and reliability.

Telecommunications

Telecommunications equipment, such as routers and switches, relies on advanced electronic components. SMD tape plays a vital role in the assembly of these devices, ensuring that they meet the high standards required for performance and reliability.

Conclusion

In conclusion, Surface Mount Device tape is an indispensable tool in the electronics manufacturing industry. Its ability to enhance precision, increase efficiency, and provide component protection makes it a preferred choice for manufacturers. As technology continues to advance, the importance of SMD tape in producing smaller, more efficient electronic devices will only grow.

Related Questions

1. What is the difference between SMT and SMD?

SMT (Surface Mount Technology) refers to the method of mounting electronic components on the surface of PCBs, while SMD (Surface Mount Device) refers to the actual components used in this process.

2. How does SMD tape improve manufacturing efficiency?

SMD tape allows for automated placement of components, reducing manual handling and assembly time, which leads to increased production efficiency.

3. Can SMD tape be used for all types of electronic components?

While SMD tape is versatile and can accommodate many component types, it is primarily designed for surface mount devices. Some larger or uniquely shaped components may require different handling methods.

4. What are the key benefits of using SMT in electronics manufacturing?

The key benefits of SMT include reduced size and weight of devices, improved performance, lower production costs, and enhanced reliability of electronic assemblies.

5. How does SMD tape protect components during assembly?

SMD tape holds components securely in place during handling and assembly, preventing damage from movement or impact, and ensuring they are correctly aligned for soldering.