Content Menu

● Understanding SMT Splice Tape

● Benefits of Using SMT Splice Tape

● Applications of SMT Splice Tape

● Best Practices for Using SMT Splice Tape

● Challenges and Considerations

● Future Trends in SMT Splicing Technology

● Conclusion

● FAQ

>> 1. What is an SMT splice tool?

>> 2. How does using an SMT splice tool improve efficiency?

>> 3. What materials are commonly used in SMT splice tools?

>> 4. Can SMT splice tools be used with different types of carrier tapes?

>> 5. What support do manufacturers provide for their products?

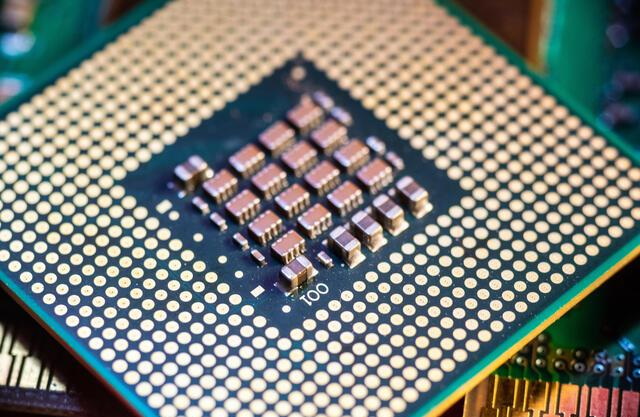

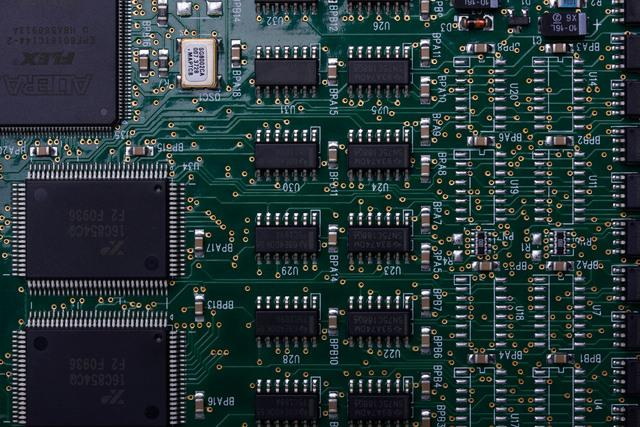

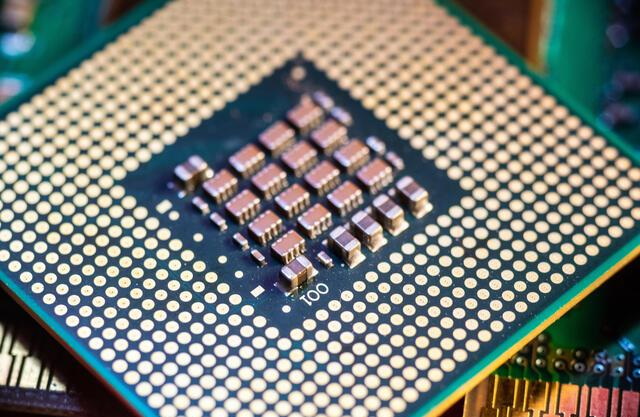

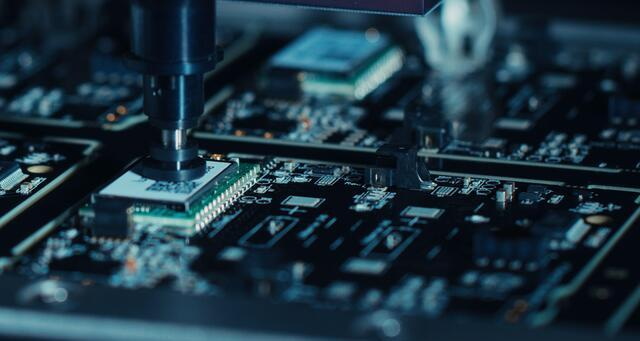

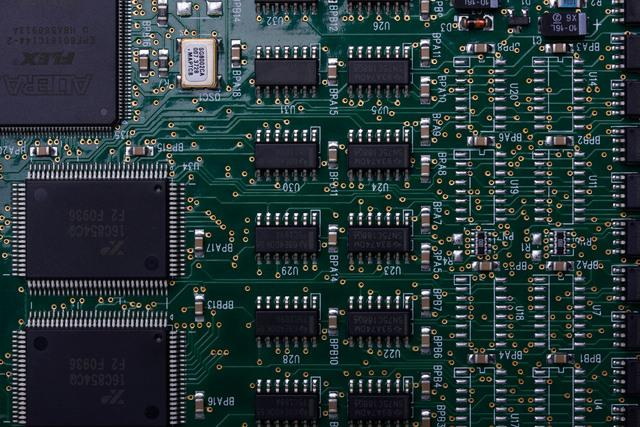

In the realm of electronics manufacturing, efficiency and precision are paramount. Surface Mount Technology (SMT) has revolutionized the way components are assembled onto printed circuit boards (PCBs), and one crucial tool in this process is SMT splice tape. This article explores the significance of SMT splice tape in PCB assembly, detailing its advantages, applications, and best practices for use.

Understanding SMT Splice Tape

SMT splice tape is a specialized adhesive tape designed to join two reels of surface mount components together. This seamless connection allows for uninterrupted production processes, which is essential in high-volume manufacturing settings. The tape is available in various types, including single-sided and double-sided options, catering to different assembly needs.

- Single-Sided SMT Splice Tape: Ideal for high-speed assembly processes where one end of a reel needs to be connected to another.

- Double-Sided SMT Splice Tape: Used for lower-speed processes requiring a smaller quantity of components.

This tape typically features a strong adhesive that ensures a secure bond between the two ends of the carrier tape, preventing any misalignment or component loss during the assembly process. The design also allows for easy application, making it user-friendly for operators on the production floor.

Benefits of Using SMT Splice Tape

The use of SMT splice tape offers several significant advantages that can enhance manufacturing efficiency:

- Increased Efficiency: By enabling continuous production without interruptions, manufacturers can significantly boost output rates. This efficiency translates into higher profitability as production lines remain active longer.

- Cost Savings: Traditional methods require stopping production to load a new reel when one runs out, which can be costly. SMT splice tapes allow for quick joining of reels, minimizing lost production time.

- Improved Accuracy: Automated splicing techniques ensure that components are joined with high precision, leading to consistent placement on PCBs. This accuracy reduces the likelihood of defects in the final product, enhancing overall quality.

- User-Friendly Application: Designed for easy application, these tapes integrate well with standard SMT pick-and-place feeders. Operators can quickly learn how to use them effectively without extensive training.

- Versatile Compatibility: Available in different sizes and thicknesses, they cater to various component types and assembly requirements. This versatility makes them suitable for a wide range of applications across different industries.

- Reduced Waste: By minimizing the need to discard partially used reels, SMT splice tape helps reduce material waste, contributing to more sustainable manufacturing practices.

Applications of SMT Splice Tape

SMT splice tape is widely used across various sectors within electronics manufacturing:

- Consumer Electronics: Essential for assembling devices like smartphones and tablets where rapid production is critical to meet market demands.

- Automotive Industry: Critical for producing components such as sensors and control modules that require high reliability and precision.

- Industrial Automation: Important for manufacturing machinery and equipment where downtime can lead to significant losses in productivity.

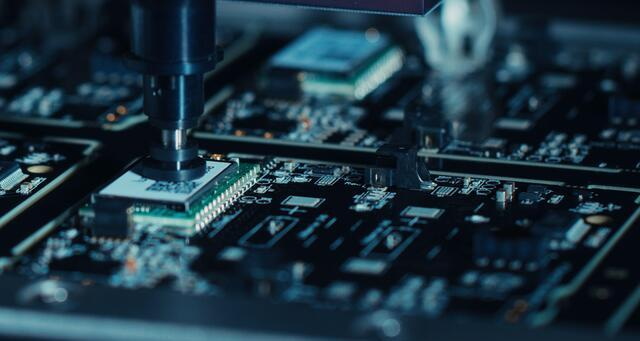

The ability to maintain continuous operation in pick-and-place machines is vital across these sectors, making SMT splice tape an invaluable tool. Additionally, as technology advances and component sizes shrink, the demand for precise assembly techniques will only increase, further solidifying the role of SMT splice tape in modern manufacturing processes.

Best Practices for Using SMT Splice Tape

To maximize the benefits of SMT splicing, manufacturers should adhere to best practices:

1. Quality Assurance: Invest in high-quality splice tapes from reputable suppliers to minimize risks associated with blockages and misfeeds. Quality tapes are less likely to cause disruptions in the production process.

2. Proper Training: Ensure that personnel are well-trained in splicing techniques to maintain consistency and accuracy during assembly. Regular workshops or training sessions can help keep skills sharp.

3. Regular Maintenance: Keep splicing tools and machines well-maintained to ensure optimal performance throughout the production process. Scheduled maintenance checks can help identify issues before they lead to downtime.

4. Monitoring and Feedback: Implement monitoring systems that provide real-time feedback on splicing effectiveness and component flow. Data analytics can help identify patterns that lead to improved processes over time.

5. Choosing the Right Type of Tape: Depending on the speed and type of assembly process, selecting the appropriate type of SMT splice tape is crucial for achieving desired results. Manufacturers should evaluate their specific needs before making a selection.

6. Environmental Considerations: Consider using eco-friendly splice tapes that minimize environmental impact while maintaining performance standards. Sustainable materials are becoming increasingly important in modern manufacturing practices.

Challenges and Considerations

While SMT splice tapes offer numerous advantages, there are challenges that manufacturers may face:

- Initial Investment Costs: High-quality splice tools can represent a significant upfront investment; however, they often pay off through increased efficiency and reduced waste over time.

- Training Requirements: Operators must be trained effectively to use these tools without causing errors during splicing. Continuous education on new technologies can also be beneficial as industry standards evolve.

- Maintenance Needs: Regular maintenance is necessary to ensure optimal performance; neglecting this can lead to inefficiencies or failures in the assembly line. Establishing a maintenance schedule can help mitigate these risks.

- Compatibility Issues: Not all splice tapes are compatible with every type of component or machine; therefore, careful selection based on specific operational requirements is essential.

Future Trends in SMT Splicing Technology

As technology continues to evolve, so too do the capabilities of SMT splice tools. Future trends may include:

- Automation Integration: Increasingly automated solutions that reduce manual handling during splicing will likely become standard practice in modern manufacturing environments. Automation not only speeds up processes but also enhances accuracy by minimizing human error.

- Smart Technology Features: Incorporating sensors and connectivity options for real-time monitoring and diagnostics could enhance operational efficiency further. Smart technologies could provide alerts when issues arise or when maintenance is required.

- Sustainability Initiatives: Developing eco-friendly materials for splice tools will help minimize environmental impact while maintaining performance standards. As sustainability becomes a priority across industries, manufacturers will need to adapt their practices accordingly.

- Advanced Material Development: Research into new adhesive technologies could lead to even stronger bonds with less material usage, enhancing both performance and sustainability efforts within PCB assembly processes.

Conclusion

In conclusion, SMT splice tape plays a pivotal role in modern electronics manufacturing by enhancing efficiency, reducing costs, and ensuring smooth production processes. By utilizing high-quality SMT splice tapes and following best practices, manufacturers can achieve seamless production workflows that contribute significantly to overall success in the industry. As technology continues to advance, staying informed about innovations will be crucial for maintaining competitive advantages in an ever-evolving market.

FAQ

1. What is an SMT splice tool?

An SMT splice tool is a device used to join two ends of carrier tape, facilitating seamless transitions between reels during production.

2. How does using an SMT splice tool improve efficiency?

It reduces downtime by allowing quick changes between component reels, maintaining continuous operation in pick-and-place machines.

3. What materials are commonly used in SMT splice tools?

Most splice tools are made from durable materials such as stainless steel or high-quality plastics designed for longevity.

4. Can SMT splice tools be used with different types of carrier tapes?

Yes, they are compatible with both plastic and paper carrier tapes commonly used in electronics manufacturing.

5. What support do manufacturers provide for their products?

Manufacturers often offer technical support, training, and a range of splicing products to help optimize operations within production environments.