Content Menu

● Understanding SMT Technology

>> Key Advantages of SMT

● Components of a Wholesale LED SMT Production Line

● Benefits of Investing in a Wholesale LED SMT Production Line

>> 1. Efficiency and Speed

>> 2. Consistency and Quality

>> 3. Cost-Effectiveness

● Setting Up a Wholesale LED SMT Production Line

>> Initial Planning and Design

>> Selecting the Right Equipment

>> Layout Optimization

● The Role of Automation in LED SMT Production

>> Improving Inspection Processes

>> Reducing Labor Costs

● Challenges in Wholesale LED SMT Production

● Case Study: Successful Implementation of a Wholesale LED SMT Production Line

>> Implementation Process

>> Results Achieved

● Conclusion

● FAQ

>> 1. What is Surface Mount Technology (SMT)?

>> 2. How does an SMT production line improve efficiency?

>> 3. What types of inspections are performed during SMT assembly?

>> 4. What challenges might arise when implementing an SMT line?

>> 5. How does investing in an SMT line impact long-term costs?

● Citations:

The demand for LED lighting solutions has surged in recent years due to their energy efficiency, longevity, and versatility. As the market expands, manufacturers are increasingly turning to wholesale LED Surface Mount Technology (SMT) production lines to meet the growing demand. This article explores the compelling reasons to invest in a wholesale LED SMT production line, detailing its benefits, components, and the overall impact on manufacturing efficiency.

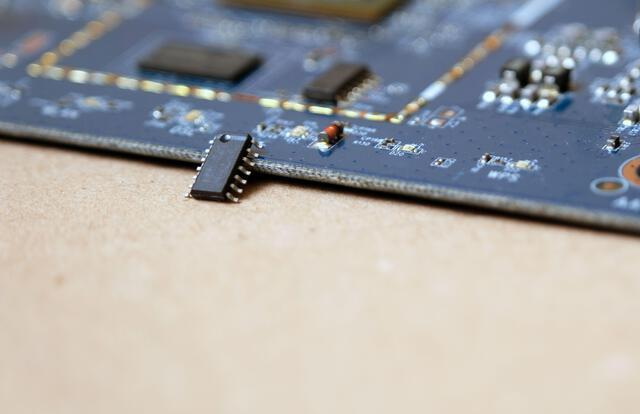

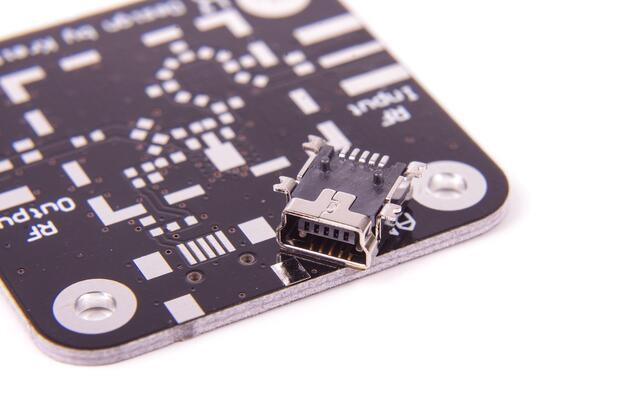

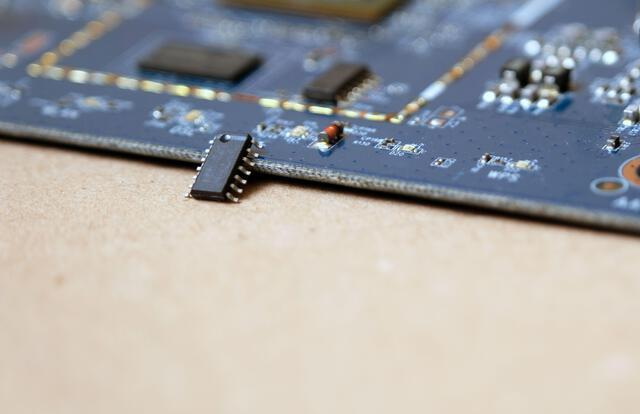

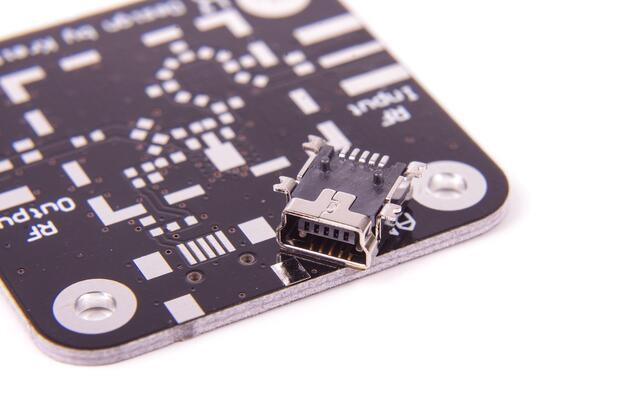

Understanding SMT Technology

Surface Mount Technology (SMT) is a method used in electronics manufacturing where components are mounted directly onto the surface of printed circuit boards (PCBs). This technology has revolutionized the way electronic devices are assembled, leading to significant improvements in production speed, efficiency, and product quality.

Key Advantages of SMT

- Higher Component Density: SMT allows for more components to be placed closer together on a PCB, which is crucial for modern electronic devices that require compact designs.

- Reduced Manufacturing Costs: By minimizing the number of steps required in assembly and allowing for automation, SMT reduces labor costs and material waste.

- Improved Reliability: The automated processes involved in SMT lead to fewer defects and higher quality products.

Components of a Wholesale LED SMT Production Line

A typical wholesale LED SMT production line consists of several key components that work together to ensure efficient manufacturing:

- Solder Paste Printer: This machine applies solder paste to the PCB where components will be placed. Precision is critical to ensure strong and reliable solder joints.

- Pick and Place Machine: This machine accurately places LED components onto the PCB. Speed and accuracy are crucial, especially in a wholesale production environment.

- Reflow Oven: After component placement, PCBs pass through a reflow oven where solder paste is melted to create strong bonds between components and the PCB.

- Automated Optical Inspection (AOI) Machine: This machine inspects PCBs for defects such as missing components or misalignment. High-quality standards are essential for maintaining customer satisfaction.

Benefits of Investing in a Wholesale LED SMT Production Line

1. Efficiency and Speed

A well-optimized SMT production line can handle large volumes of LEDs with high precision and speed. This capability is crucial for meeting wholesale demands where time-to-market can significantly affect competitiveness.

2. Consistency and Quality

Automation in SMT production lines ensures consistent quality across all produced units, reducing the risk of defects. High-quality production leads to enhanced reliability and customer satisfaction, which are vital for repeat business and brand reputation.

3. Cost-Effectiveness

By streamlining processes and minimizing manual intervention, a wholesale LED SMT production line can significantly reduce labor costs and material waste. The initial investment can be offset by long-term savings through improved operational efficiency.

Setting Up a Wholesale LED SMT Production Line

Initial Planning and Design

Setting up an effective wholesale LED SMT production line requires careful planning. Manufacturers must assess their production requirements, including types of LEDs to be produced, expected volumes, and quality standards. This information will guide equipment selection and layout design.

Selecting the Right Equipment

Investing in high-quality equipment is crucial for success. Each component—from solder paste printers to AOI machines—should be selected based on performance, reliability, and compatibility with other machines in the line. Scalability is also an important consideration for future growth.

Layout Optimization

The layout of the production line should minimize material handling while maximizing efficiency. A well-organized workflow ensures smooth transitions between stages of production, reducing bottlenecks and downtime.

The Role of Automation in LED SMT Production

Automation enhances precision during component placement and reflow soldering stages. Automated pick-and-place machines can position components with remarkable accuracy, ensuring proper alignment—a feat difficult to achieve manually.

Improving Inspection Processes

Automated Optical Inspection (AOI) systems are essential for maintaining high-quality standards in wholesale LED production. These systems detect defects early in the process, preventing faulty products from reaching customers.

Reducing Labor Costs

By automating key stages of production, manufacturers can significantly lower labor costs while still requiring skilled technicians for equipment operation and maintenance. This reduction provides a competitive edge in price-sensitive markets.

Challenges in Wholesale LED SMT Production

While investing in an SMT production line offers numerous benefits, challenges exist:

- Managing Production Volume: Balancing high-volume production with flexibility can be challenging as manufacturers may need to adapt quickly to changing market demands.

- Ensuring Component Quality: The final product's quality heavily relies on sourcing high-quality components. Establishing strong relationships with reputable suppliers is crucial.

- Keeping Up with Technological Advancements: The fast-paced nature of technology requires manufacturers to stay updated with new techniques and equipment to maintain competitiveness.

Case Study: Successful Implementation of a Wholesale LED SMT Production Line

XYZ Lighting Solutions recently upgraded their facilities with a state-of-the-art wholesale LED SMT production line aimed at increasing capacity while reducing costs.

Implementation Process

The implementation began with assessing their needs followed by selecting high-performance equipment tailored for their specific requirements. A modular layout was designed to facilitate quick reconfiguration for different products.

Results Achieved

The new production line resulted in increased output while maintaining high-quality standards. The company reported reduced operational costs due to enhanced efficiency and minimized waste.

Conclusion

Investing in a wholesale LED SMT production line is not merely about meeting current demand; it is about preparing for future growth within the rapidly evolving LED industry. The combination of advanced automation with meticulous quality control enables manufacturers to produce high volumes of LEDs efficiently and consistently. As technology continues to advance, those who embrace these innovations will be well-positioned to lead the market by delivering high-quality products at competitive prices.

FAQ

1. What is Surface Mount Technology (SMT)?

SMT is an assembly method where electronic components are mounted directly onto the surface of PCBs without drilling holes, allowing for higher density layouts and faster assembly times.

2. How does an SMT production line improve efficiency?

By automating key processes such as solder paste application, component placement, and inspection, an SMT production line significantly reduces manual labor requirements while increasing speed and accuracy.

3. What types of inspections are performed during SMT assembly?

Inspections typically include Automated Optical Inspection (AOI) for detecting placement errors or defects after assembly, ensuring that only quality products reach customers.

4. What challenges might arise when implementing an SMT line?

Challenges include managing large volumes while maintaining flexibility for different products, ensuring component quality from suppliers, and keeping up with rapid technological advancements.

5. How does investing in an SMT line impact long-term costs?

While initial investments can be substantial, automation leads to reduced labor costs, minimized waste, improved product quality, and ultimately lower operational costs over time.

Citations:

[1] https://de.hct-smt.com/blog/wholesale-led-smt-production-line--revolutionizing-the-led-manufacturing-industry

[2] https://www.viasion.com/blog/smt-assembly-and-its-advantages/

[3] https://www.hayawin.com/resources/smt-line-an-efficient-and-cost-effective-production-line.html

[4] https://en.rangdong.com.vn/news/overview-of-a-smt-production-line

[5] https://faroads.com/start-smt-line-guide-2024/

[6] https://www.pcbcart.com/article/content/smt-process-to-cost-reduction.html

[7] https://www.smtfactory.com/Exploring-SMT-Line-Cost-Factors-and-Savings-id43117676.html

[8] https://www.protoexpress.com/blog/good-not-so-good-sides-surface-mount-technology/

[9] https://smtmachineline.com/smt-line-solution/

[10] https://www.venture-mfg.com/smt-manufacturing/

[11] https://www.smtfactory.com/Expert-Guidance-for-SMT-Production-Line-Setup-id42117676.html

[12] https://www.assemcorp.com/en/frequently-asked-questions.html

[13] https://www.smtmachine.eu/role-of-smt-production-line-in-the-led-industry/

[14] https://versae.com/smt-assembly-faq/

[15] https://en.rangdong.com.vn/news/overview-of-a-smt-production-line

[16] https://www.smtfactory.com/I-C-T-Smt-Led-Module-Manufacturing-Assembly-Line-pd711991198.html

[17] https://www.smtfactory.com/What-are-the-applications-of-SMT-in-the-LED-industry-id45455527.html

[18] https://www.allsmt.com/SMT-line-concept-assembly-manufacturing-production-Assembly

[19] https://www.lumitronix.com/en/smt-fertigung

[20] https://ko.hct-smt.com/blog/comprehensive-guide-to-led-smt-production-line

[21] https://www.linkedin.com/pulse/revolutionize-led-production-discover-how-smt-lines-shaping-wang-mqdkc

[22] https://www.linkedin.com/pulse/advantages-smt-manufacturing-practical-cost-effective-nyn3c

[23] https://www.shine.lighting/threads/what-is-an-smd-led.152/

[24] https://www.tytech-smt.com/smt-production-line-pcb-pick-and-place-machine-with-good-price/

[25] http://en.tjbbbjk.com/a/101067.html

[26] https://www.smtfactory.com/Exploring-SMT-Line-Cost-Factors-and-Savings-id43117676.html

[27] https://fireflyled.com/faq/

[28] https://www.smtfactory.com/What-is-the-LED-Display-SMT-Production-Process-id41946657.html

[29] https://www.wevolver.com/article/smt-process

[30] https://jhdpcb.com/blog/efficient-smt-assembly/

[31] https://global.yamaha-motor.com/business/smt/faq/

[32] https://www.pcbcart.com/article/content/qa-about-smt-assembly.html

[33] https://www.linkedin.com/pulse/ins-outs-setting-up-smt-factory-prototype-pcb-assembly-yljdc

[34] https://www.smthelp.com/frequently-asked-s-k100-high-speed-led-pick-place-machine-questions-and-answers/

[35] https://www.manncorp.com/pages/purchasing-smt-equipment-how-to

[36] https://www.smtmachine.eu/role-of-smt-production-line-in-the-led-industry/