Content Menu

>> Introduction to Used SMT Machines

>> Benefits of Using Used SMT Machines

>> Considerations When Buying Used SMT Machines

>> Types of Used SMT Machines Available

>> Case Studies: Successful Implementation of Used SMT Machines

>>> Case Study 1: Small Electronics Manufacturer

>>> Case Study 2: Large OEM Transitioning Production Lines

>> Future Trends in Used SMT Machines Market

>> Conclusion

>> Frequently Asked Questions

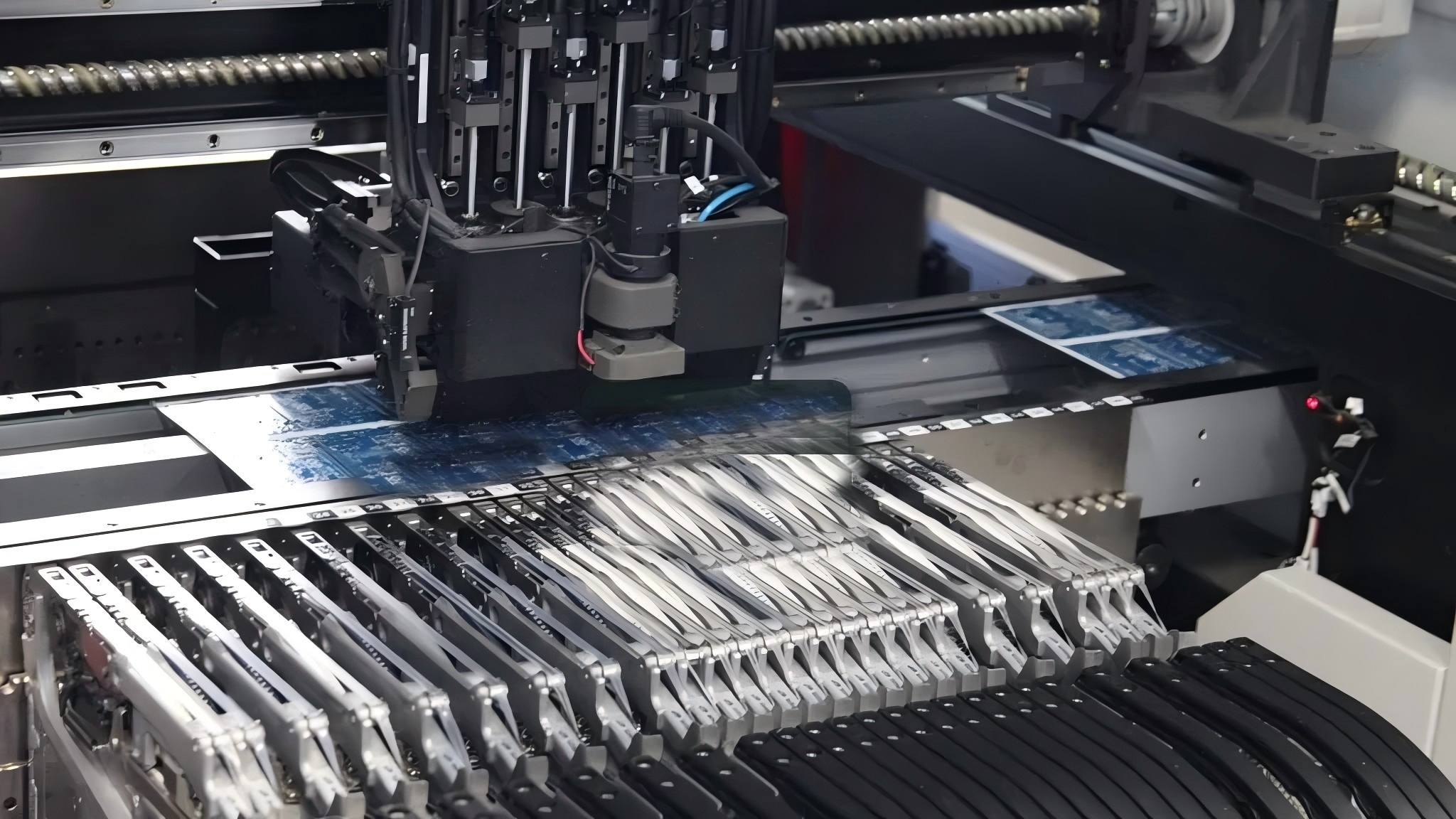

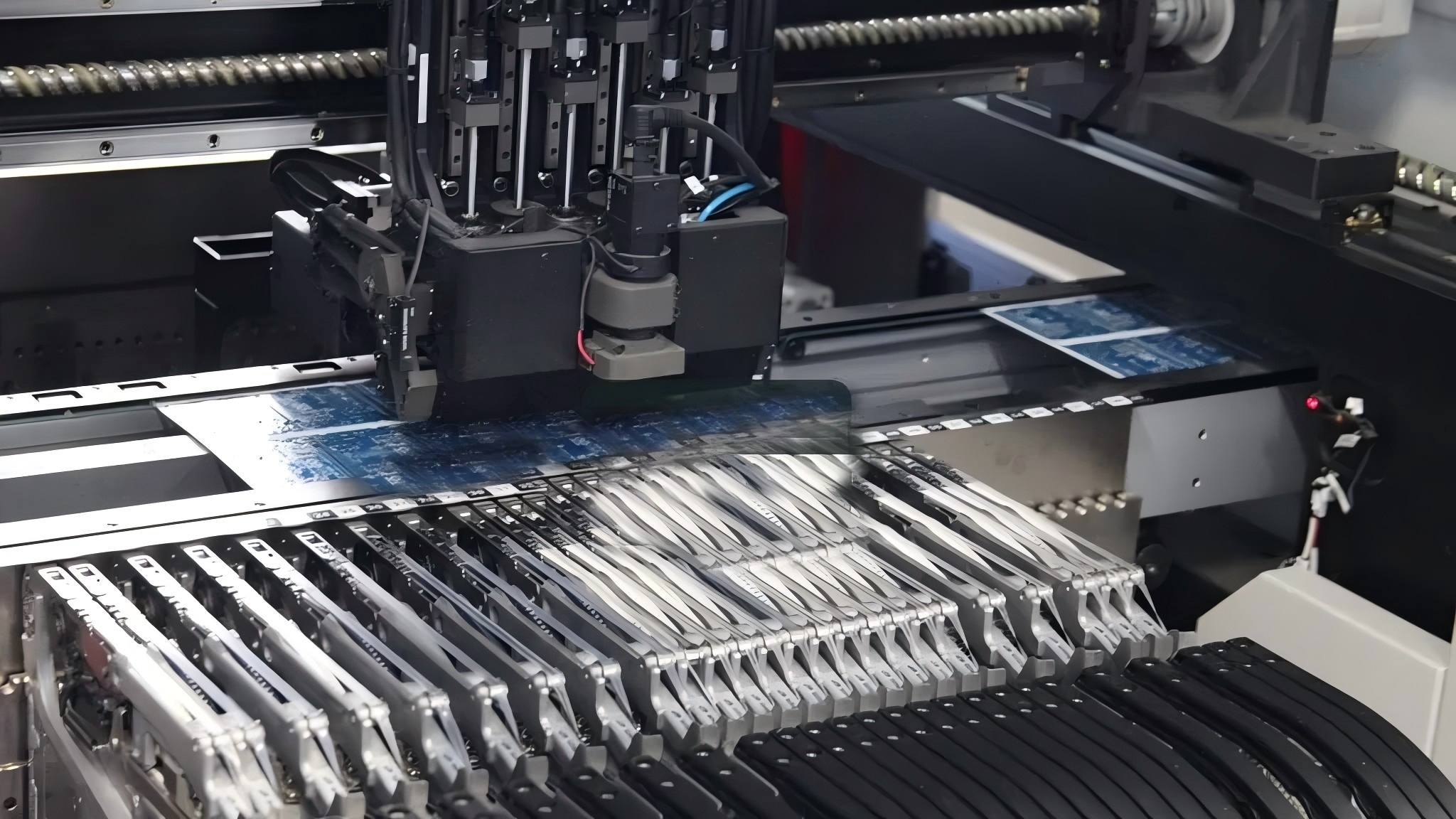

Introduction to Used SMT Machines

Used SMT machines refer to pre-owned equipment utilized in the assembly of electronic components onto printed circuit boards (PCBs). These machines play a crucial role in the SMT process, which has become the industry standard for producing compact and efficient electronic devices. Companies like Global Soul Limited (GS-SMT LTD), based in Shenzhen, China, specialize in providing solutions for SMT and can guide manufacturers in selecting appropriate used equipment.

Benefits of Using Used SMT Machines

1. Cost Savings: The most apparent advantage of purchasing used SMT machines is cost savings. New machines can cost hundreds of thousands of dollars, while used machines can often be acquired for a fraction of that price. This allows companies to allocate resources to other critical areas such as research and development or marketing.

2. Immediate Availability: Used SMT machines are often readily available for purchase, allowing manufacturers to quickly ramp up production without waiting for new equipment to be manufactured and delivered. This immediacy can be crucial for businesses looking to meet tight deadlines.

3. Proven Performance: Many used SMT machines come from reputable manufacturers and have been tested in real-world production environments. This history can provide confidence in their reliability and performance compared to untested new models.

4. Lower Depreciation Rates: New equipment typically depreciates quickly, losing value as soon as it is purchased. Used machines have already undergone this initial depreciation, making them a more stable investment.

5. Flexibility in Production: With lower costs associated with acquiring used equipment, manufacturers can afford to diversify their production capabilities by investing in multiple types of used SMT machines. This flexibility allows them to adapt to changing market demands more effectively.

Considerations When Buying Used SMT Machines

While there are numerous advantages to purchasing used SMT machines, there are also important considerations:

1. Condition and Maintenance History: It is essential to assess the condition of the used machine thoroughly before purchase. Request maintenance records and inspect the machine for any signs of wear or damage.

2. Compatibility with Existing Systems: Ensure that any used SMT machine you consider is compatible with your current production line and technology stack. Compatibility issues can lead to additional costs and complications during installation.

3. Availability of Spare Parts: Check the availability of spare parts for the specific model you are considering. Some older models may have limited support, making repairs more challenging.

4. Vendor Reputation: Purchase from reputable vendors who provide warranties or guarantees on their used equipment. This assurance can protect your investment and provide peace of mind.

5. Technological Advancements: Consider whether the technology in the used machine meets your production needs or if newer models offer significant advantages that justify their higher costs.

Types of Used SMT Machines Available

The market for used SMT machines is diverse, offering various types suited for different aspects of the manufacturing process:

- Pick and Place Machines: These are essential for placing components onto PCBs accurately and efficiently.

- Screen Printers: Used for applying solder paste onto PCBs before component placement.

- Reflow Ovens: Critical for melting solder paste to create electrical connections between components and PCBs.

- Wave Soldering Machines: Used primarily for through-hole components but still relevant in hybrid assembly processes.

- Inspection Equipment: Automated Optical Inspection (AOI) systems ensure quality control by detecting defects on assembled boards.

Case Studies: Successful Implementation of Used SMT Machines

Case Study 1: Small Electronics Manufacturer

A small electronics manufacturer faced challenges with high production costs due to expensive new machinery. By investing in high-quality used SMT machines, they reduced their capital expenditure significantly while maintaining production quality. This strategic move allowed them to expand their product line without incurring substantial debt.

Case Study 2: Large OEM Transitioning Production Lines

A large Original Equipment Manufacturer (OEM) was transitioning its production lines to accommodate new product designs. Instead of investing heavily in new equipment, they opted for a mix of refurbished pick and place machines and reflow ovens from trusted suppliers. This approach minimized downtime during the transition phase while ensuring that production goals were met efficiently.

Future Trends in Used SMT Machines Market

As technology continues to evolve, several trends are emerging within the used SMT machine market:

1. Increased Automation: The trend towards automation will continue to influence the types of used equipment available, with many older models being upgraded or replaced by more advanced systems that offer greater efficiency.

2. Sustainability Concerns: As environmental awareness grows, manufacturers may increasingly turn to refurbished equipment as a sustainable option compared to purchasing new machinery that contributes to waste.

3. Enhanced Digital Integration: The integration of IoT technologies into manufacturing processes means that even older models can be retrofitted with digital capabilities, making them more attractive options for buyers looking for modern features at lower prices.

4. Global Market Expansion: The demand for used SMT machines is likely to grow globally as more manufacturers seek cost-effective solutions regardless of geographical location.

5. Online Marketplaces: The rise of online platforms dedicated to buying and selling used machinery will make it easier for manufacturers to find suitable equipment quickly.

Conclusion

Used SMT machines represent a valuable opportunity for electronics manufacturers seeking cost-effective solutions without compromising on quality or efficiency. By carefully considering factors such as condition, compatibility, vendor reputation, and technological advancements, companies can make informed decisions that enhance their production capabilities while managing costs effectively.

Frequently Asked Questions

1. What are used SMT machines?

- Used SMT machines are pre-owned equipment utilized in the assembly of electronic components onto printed circuit boards (PCBs).

2. What are the benefits of purchasing used SMT machines?

- Benefits include cost savings, immediate availability, proven performance, lower depreciation rates, and increased flexibility in production.

3. How do I assess the condition of a used SMT machine?

- Request maintenance records, inspect the machine physically, and consider having it evaluated by a technician before purchase.

4. Are there specific types of used SMT machines?

- Yes, common types include pick and place machines, screen printers, reflow ovens, wave soldering machines, and inspection equipment.

5. What trends are shaping the future market for used SMT machines?

- Trends include increased automation, sustainability concerns, enhanced digital integration, global market expansion, and online marketplaces facilitating transactions.