Content Menu

● Introduction to SMD Pick and Place Machines

>> Benefits of Homemade Machines

● Designing a Homemade SMD Pick and Place Machine

>> Mechanical Components

>> Electronic Components

>> Software Integration

● Building a Homemade SMD Pick and Place Machine

>> Step-by-Step Guide

● Benefits of Using a Homemade SMD Pick and Place Machine

>> Speed and Precision

>> Flexibility and Customization

● Challenges and Limitations

● Real-World Applications and Examples

>> OpenPnP Framework

>> Manual vs. Automated Machines

● Preventive Maintenance for SMD Pick and Place Machines

● Conclusion

● FAQ

>> 1. What are the primary components of a homemade SMD pick and place machine?

>> 2. How much does it cost to build a homemade SMD pick and place machine?

>> 3. What software can be used to control a homemade SMD pick and place machine?

>> 4. What are the benefits of using a homemade SMD pick and place machine over manual placement?

>> 5. Can a homemade SMD pick and place machine be used for large-scale production?

● Citations:

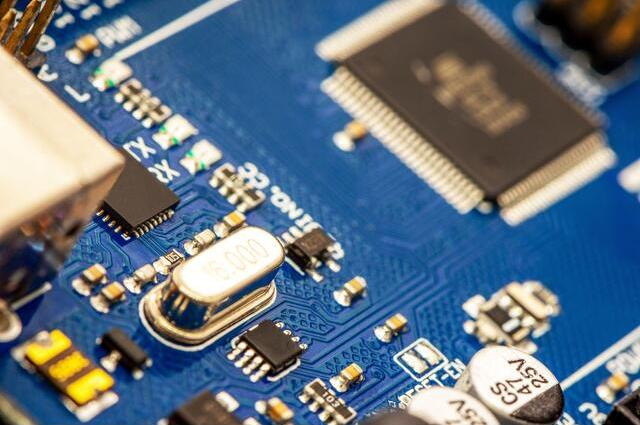

In the realm of electronics manufacturing, Surface Mount Devices (SMDs) have become ubiquitous due to their compact size and efficiency. However, handling these tiny components can be challenging, especially for hobbyists or small-scale manufacturers. This is where a homemade SMD pick and place machine comes into play, offering a cost-effective solution for assembling electronic circuits with precision and speed. In this article, we will explore the benefits and practicalities of building your own homemade SMD pick and place machine.

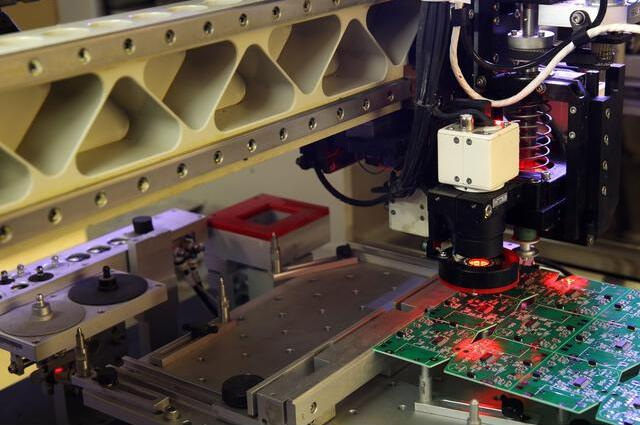

Introduction to SMD Pick and Place Machines

SMD pick and place machines are essential tools in modern electronics manufacturing. They automate the process of placing SMD components onto printed circuit boards (PCBs), significantly improving assembly speed and accuracy compared to manual placement. Commercial machines are highly sophisticated but also expensive, making them inaccessible to many hobbyists and small businesses.

Benefits of Homemade Machines

Building a homemade SMD pick and place machine offers several advantages:

1. Cost Savings: Commercial pick and place machines can cost thousands of dollars. In contrast, a homemade version can be built for a fraction of the cost, often under $100 for manual versions or a few hundred dollars for more automated setups.

2. Customization: By designing and building your own machine, you can tailor it to your specific needs, whether it's for small batch production or prototyping.

3. Learning Experience: The process of building a homemade machine provides valuable hands-on experience with electronics, mechanics, and automation.

4. Flexibility: Homemade machines can be easily modified or upgraded as new components or technologies become available.

Designing a Homemade SMD Pick and Place Machine

Designing a homemade SMD pick and place machine involves several key components and considerations:

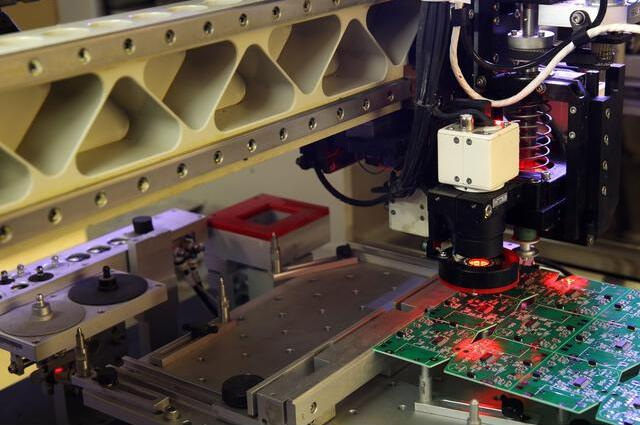

Mechanical Components

- Linear Bearings: These are crucial for smooth X-Y movement. They can be mounted on lead rods or other materials like aluminum profiles.

- Actuation System: This can range from manual operation using a foot pedal to automated systems using stepper motors and belts.

- Nozzle System: A vacuum pump and a syringe or similar mechanism are often used to pick up components.

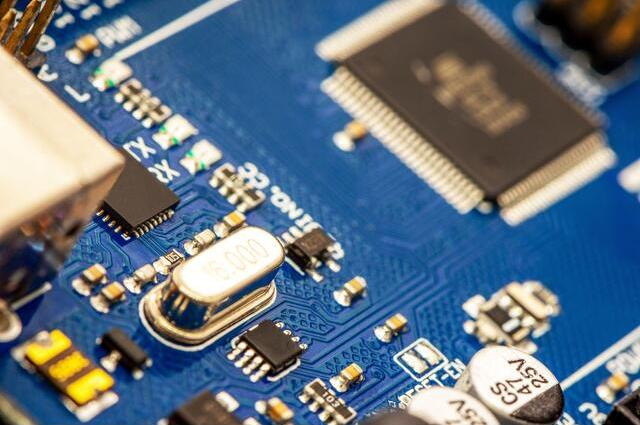

Electronic Components

- Control System: For automated versions, a control board like Ramps 1.4 can be used to manage stepper motors and execute G-code commands.

- Power Supply: A reliable power supply is necessary to ensure consistent operation.

Software Integration

- G-Code Generation: Software like Eagle or KiCAD can generate G-code for automated placement.

- OpenPnP Framework: This open-source framework provides advanced features like automatic nozzle change and vision systems for precise placement.

Building a Homemade SMD Pick and Place Machine

Step-by-Step Guide

1. Plan Your Design: Determine the size and complexity of your machine based on your needs.

2. Gather Materials: Acquire necessary components such as linear bearings, stepper motors, and control boards.

3. Assemble the Frame: Use materials like plywood or MDF for the base and acrylic for mounting parts.

4. Implement Actuation: Install stepper motors and belts for X-Y movement and a threaded rod for Z-axis control.

5. Integrate Electronics: Connect the control board, power supply, and other electronic components.

6. Test and Refine: Ensure all movements are precise and reliable, making adjustments as needed.

Benefits of Using a Homemade SMD Pick and Place Machine

Speed and Precision

- Increased Efficiency: Automating the placement process significantly speeds up assembly compared to manual methods.

- Improved Accuracy: Even manual homemade machines can offer better precision than manual tweezers, reducing errors and improving product quality.

Flexibility and Customization

- Adaptability: Homemade machines can be easily modified to handle different component sizes or types.

- Cost-Effectiveness: By reducing labor time and improving yield, these machines can be cost-effective for small-scale production.

Challenges and Limitations

While building a homemade SMD pick and place machine offers many benefits, there are also challenges:

- Technical Complexity: Designing and building an automated machine requires significant technical knowledge.

- Precision Requirements: Achieving high precision can be difficult without advanced components or calibration.

- Scalability: Homemade machines may not be suitable for large-scale production due to limitations in speed and capacity.

Real-World Applications and Examples

Several projects have successfully demonstrated the feasibility of homemade SMD pick and place machines. For instance, a DIY project featured on DZone utilized the OpenPnP framework to create a reliable and flexible machine capable of handling small batches of PCBs[1]. Another example involves a manual pick and place machine designed with a microscope for enhanced precision, highlighting the potential for customization in these projects[4].

OpenPnP Framework

The OpenPnP framework is particularly useful for building homemade machines. It provides a comprehensive set of tools for managing the placement process, including automatic nozzle change and vision systems. This framework allows users to import CAD data from software like KiCAD or Eagle, ensuring accurate component placement[1].

Manual vs. Automated Machines

Manual machines are simpler and less expensive but require more labor. They are ideal for small batches or prototyping where precision is crucial but speed is not a priority. Automated machines, on the other hand, offer higher efficiency and are better suited for small-scale production. However, they require more complex electronics and programming.

Preventive Maintenance for SMD Pick and Place Machines

To ensure optimal performance of both homemade and commercial SMD pick and place machines, regular maintenance is crucial. Common issues include component placement errors, component damage, and nozzle problems. These can be mitigated by:

- Calibration: Regularly calibrate the machine to ensure accurate component placement.

- Nozzle Maintenance: Check and replace nozzles regularly to prevent sticking or damage.

- Feeders: Ensure feeders are properly aligned and maintained to prevent component mispicking[2][6].

Conclusion

Building a homemade SMD pick and place machine is a rewarding project that can greatly enhance your electronics assembly capabilities. Whether you opt for a manual or automated design, the benefits of cost savings, customization, and learning experience make it a worthwhile endeavor. As technology continues to evolve, the possibilities for improving these machines are endless, making them an exciting project for hobbyists and small manufacturers alike.

FAQ

1. What are the primary components of a homemade SMD pick and place machine?

A homemade SMD pick and place machine typically includes linear bearings for movement, a control system (manual or automated), a nozzle system for picking components, and a frame to hold everything together.

2. How much does it cost to build a homemade SMD pick and place machine?

The cost can vary widely depending on the complexity and automation level. Manual versions can be built for under $100, while more automated setups might cost a few hundred dollars.

3. What software can be used to control a homemade SMD pick and place machine?

Software like Eagle or KiCAD can generate G-code for automated placement. Additionally, frameworks like OpenPnP offer advanced features for precise component placement.

4. What are the benefits of using a homemade SMD pick and place machine over manual placement?

Homemade machines offer increased speed, improved precision, and reduced labor time compared to manual placement methods. They also provide a cost-effective solution for small-scale production.

5. Can a homemade SMD pick and place machine be used for large-scale production?

While homemade machines are excellent for small batches and prototyping, they may not be suitable for large-scale production due to limitations in speed and capacity. Commercial machines are generally more appropriate for high-volume manufacturing.

Citations:

[1] https://dzone.com/articles/diy-smt-pick-and-place-machine-with-openpnp

[2] https://www.zjyingxing.com/info/what-are-the-common-smt-pick-and-place-machine-88387624.html

[3] https://www.stm32duino.com/viewtopic.php?t=725

[4] https://hackaday.com/2015/02/05/diy-smd-twofer-manual-pick-and-place-and-the-beak/

[5] https://www.instructables.com/Ramps-14-DIY-SMD-Pick-and-Place/

[6] https://iconnect007.com/index.php/article/52613/smt-preventive-maintenance-stop-5-major-problems-with-pick-and-place-nozzles/52616

[7] https://www.eevblog.com/forum/manufacture/the-reality-of-a-pick-and-place-lifestyle/

[8] https://www.instructables.com/Manual-Pick-and-Place-Machine-for-SMD-Components/

[9] https://lowpowerlab.com/2014/05/19/pick-and-place-entry-level-options/

[10] https://www.youtube.com/watch?v=E3FVA-jhjgQ

[11] http://www.gaudi.ch/GaudiLabs/?page_id=213

[12] https://www.protoexpress.com/blog/common-errors-surface-mount-technology-smt/

[13] https://www.reddit.com/r/ECE/comments/po8qbj/any_recommendations_for_cheap_pick_and_place/

[14] https://mcuoneclipse.com/2018/06/26/building-a-diy-smt-pickplace-machine-with-openpnp/

[15] https://amesberger.wordpress.com/2013/07/18/diy-pick-and-place-machine/

[16] http://dangerousprototypes.com/blog/2012/11/24/diy-low-budget-manual-pick-place/

[17] https://www.cnczone.com/forums/rc-robotics-and-autonomous-robots/97551-eclipzes-smd-picknplace-build-34.html

[18] https://groupdiy.com/threads/interest-in-diy-smd-tools.45094/

[19] https://www.youtube.com/watch?v=wN_XDsfzgYg

[20] https://www.youtube.com/watch?v=s5Qaxi2uEhw