Content Menu

● Introduction to SMT Reel Storage Racks

>> Benefits of SMT Reel Storage Racks

● Features of SMT Reel Storage Racks

● Types of SMT Reel Storage Racks

● Choosing the Right SMT Reel Storage Rack

>> Implementation and Integration

>> Case Studies: Successful Implementations

● Trends in SMT Reel Storage

>> Future Developments

● Conclusion

● Frequently Asked Questions

>> 1. What are the primary benefits of using SMT reel storage racks?

>> 2. How do SMT reel storage racks protect against ESD and moisture?

>> 3. Can SMT reel storage racks accommodate different reel sizes?

>> 4. What level of automation can I expect from SMT reel storage racks?

>> 5. How do I choose the right SMT reel storage rack for my factory?

● Citations:

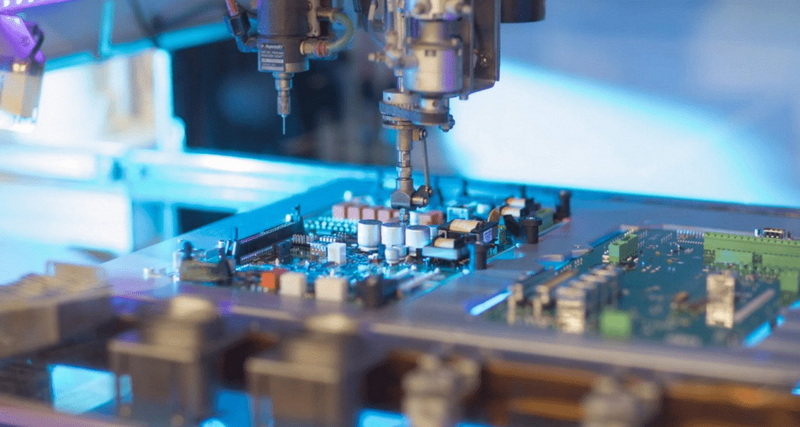

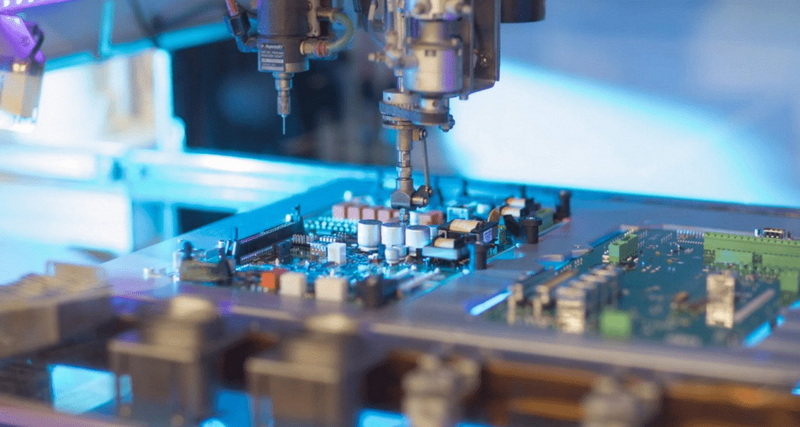

In the fast-paced world of electronics manufacturing, the efficient storage and management of electronic components are crucial for maintaining production efficiency and quality. One of the most effective solutions for storing electronic components is the use of SMT reel storage racks. These specialized storage systems are designed to optimize space, improve efficiency, and protect the integrity of electronic components. In this article, we will explore the benefits and features of SMT reel storage racks and why they are essential for electronic component management.

Introduction to SMT Reel Storage Racks

SMT reel storage racks are specifically designed for storing and managing the reels of electronic components used in surface mount technology (SMT) manufacturing. These systems play a vital role in organizing, protecting, and efficiently retrieving components for production processes. The importance of proper storage cannot be overstated, as it directly impacts component protection, inventory management, space optimization, and production efficiency.

Benefits of SMT Reel Storage Racks

1. Component Protection: Electronic components are sensitive to environmental factors such as humidity and electrostatic discharge (ESD). SMT reel storage racks often include features like ESD protection and climate control to safeguard these components. For instance, some systems use ESD-safe materials and grounding mechanisms to prevent static damage, while others incorporate climate control features to maintain stable temperature and humidity conditions[1][3].

2. Inventory Management: Efficient storage systems enable accurate tracking of component quantities and locations, reducing the risk of stockouts or overstocking. Modern SMT reel storage racks often integrate with inventory management software, providing real-time updates on stock levels and usage history[1][3].

3. Space Optimization: With the vast number of components used in electronics manufacturing, optimizing storage space is essential for efficient factory operations. SMT reel storage racks utilize vertical space effectively, allowing for high-density storage that can save up to 85% of floor space compared to traditional shelving systems[3][5].

4. Production Efficiency: Quick and easy access to required components can significantly reduce production setup times and increase overall efficiency. Advanced SMT reel storage systems offer features like guided retrieval systems and automated carousel or lift mechanisms for rapid access to stored reels[3][4].

Features of SMT Reel Storage Racks

SMT reel storage racks come with a variety of features that cater to different manufacturing needs:

- Adjustable Shelving: This allows companies to customize the storage layout to fit their specific needs and accommodate different sizes and types of reels[8].

- ESD Protection: This helps prevent damage to the electronic components due to static electricity, ensuring the longevity and reliability of these components throughout the manufacturing process[7].

- Climate Control: Maintaining stable temperature and humidity conditions prevents damage to the electronic components, ensuring they remain in optimal condition[1].

- Labelling and Identification: This helps companies quickly identify and locate specific reels of components, streamlining the production process[6].

- Security Features: These may include locks, alarms, or other measures to prevent unauthorized access or tampering with the stored components.

Types of SMT Reel Storage Racks

1. Stainless Steel SMT Reel Racks: Constructed from high-quality stainless steel, these racks are durable, corrosion-resistant, and suitable for demanding industrial environments. They provide ESD-safe storage solutions and can be customized to fit specific needs[7].

2. Quantum Reel Shelving Units: These units are designed for versatility, offering both stationary and mobile storage options. They feature chrome-plated shelves and conductive accessories for ESD safety, making them ideal for integrating into existing storage systems.

3. KenWei SMT Reel Storage Solutions: These intelligent rack systems include features like data docking with storage systems, electronic label lighting guidance, and seamless connection with WMS, ERP, MES systems. They improve efficiency and quality in material preparation and management.

4. Neo Light Plus Systems: These advanced systems combine Pick to Light technology with location sensors for material detection. They significantly improve traditional storage solutions by enhancing production efficiency and inventory management[2].

5. MYTower 7+ Component Storage: This system offers a compact footprint and high storage capacity, making it ideal for storing large quantities of reels near production lines. It provides accurate component tracking and can be integrated into existing material handling systems[5].

Choosing the Right SMT Reel Storage Rack

When selecting an SMT reel storage rack, it's crucial to consider both your current and future storage needs. Assess the number and sizes of reels you need to store and choose a system that can accommodate your requirements with room for growth. Some systems offer modular designs that allow for easy expansion as your storage needs increase, providing a cost-effective solution in the long run[3].

Implementation and Integration

Once you've chosen the right SMT reel storage rack, proper implementation is crucial to maximize its benefits. Carefully plan the placement of your storage system within your facility, considering factors such as proximity to production lines, material flow patterns, and access for maintenance and restocking. Ensure that your new storage system integrates smoothly with your existing inventory management and production planning software[3].

Case Studies: Successful Implementations

Several case studies highlight the benefits of implementing advanced SMT reel storage systems:

- Electronics Manufacturer Improves Efficiency: A medium-sized electronics manufacturer implemented a vertical carousel SMT reel storage system. The results included a 70% reduction in floor space used for component storage, a 50% decrease in time spent retrieving components, and 99.9% inventory accuracy[3].

- Large-Scale Production Facility Enhances Automation: A large electronics production facility invested in a fully automated AS/RS for SMT reel storage. The outcomes were a 90% reduction in manual handling of components, a 30% increase in overall production efficiency, and zero incidents of component mix-ups or losses[3].

Trends in SMT Reel Storage

The SMT reel storage market is witnessing significant growth driven by emerging trends such as automation, sustainability, and Industry 4.0. Advanced systems are integrating IoT devices and AI algorithms to enhance inventory management and reduce human error. This automation not only accelerates production cycles but also enhances accuracy in component retrieval.

Moreover, the emphasis on sustainability is leading manufacturers to adopt systems that optimize space and reduce waste. Modular and scalable storage solutions are becoming increasingly popular as they allow for flexible operations and quick reconfiguration without significant downtime.

Future Developments

As technology continues to evolve, we can expect SMT reel storage systems to become even more sophisticated. Future developments may include more advanced automation, enhanced data analytics for inventory management, and increased integration with smart factory technologies. These advancements will further streamline production processes, reduce costs, and improve overall efficiency.

Conclusion

In conclusion, SMT reel storage racks are indispensable for electronic component management in the manufacturing industry. They offer a range of benefits from component protection and inventory management to space optimization and production efficiency. By choosing the right SMT reel storage rack and implementing it effectively, businesses can enhance their operational efficiency, reduce costs, and improve overall quality.

Frequently Asked Questions

1. What are the primary benefits of using SMT reel storage racks?

- The primary benefits include component protection, improved inventory management, optimized space usage, and enhanced production efficiency. These systems help safeguard components from ESD and moisture, ensure accurate stock tracking, and provide quick access to components, thereby streamlining production processes[1][3].

2. How do SMT reel storage racks protect against ESD and moisture?

- SMT reel storage racks protect against ESD through the use of ESD-safe materials and grounding mechanisms. For moisture protection, some systems incorporate climate control features that regulate temperature and humidity levels within the storage environment[1][3].

3. Can SMT reel storage racks accommodate different reel sizes?

- Yes, most modern SMT reel storage racks are designed to accommodate various reel sizes. Some systems can store reels ranging from 7" to 15" in diameter and 8-56mm in width. Many systems also offer customizable storage options to fit specific needs, including storage for other component types such as tubes, trays, and mechanical parts[4][7].

4. What level of automation can I expect from SMT reel storage racks?

- The level of automation varies depending on the system. Basic systems may offer guided light systems for manual picking, while more advanced solutions provide fully automated storage and retrieval with robotic systems. Some high-end systems can integrate with AGVs for automated material transport and connect with production planning software for seamless workflow automation[3][4].

5. How do I choose the right SMT reel storage rack for my factory?

- When choosing an SMT reel storage rack, consider factors such as storage capacity, space efficiency, accessibility, inventory management, environmental control, and automation compatibility. Ensure the system integrates well with your existing processes and enhances your inventory management[3].

Citations:

[1] https://www.southwestsolutions.com/ssg/material-handling/smt-reel-storage-solutions/

[2] https://global.neotel.tech/products/neo-light-series/neo-light-plus/

[3] https://www.gssmt-parts.com/how-to-choose-the-best-smt-reel-storage-system-for-your-factory.html

[4] https://inovaxe.com/smt-reel-storage/

[5] https://www.mycronic.com/product-areas/pcb-assembly/smt/component-storage/mytower7plus/

[6] https://hawkerrichardson.com.au/product/smart-storage-rack-smt-component-management/

[7] https://www.highstartechnoloogy.com/shelving-and-trolley-products/stainless-steel-smt-reel-rack

[8] https://global.neotel.tech/2023/01/05/what-is-smt-reel-storage-solution/

[9] https://www.cluso.com.au/invman

[10] https://cornerstone.lib.mnsu.edu/cgi/viewcontent.cgi?article=2230&context=etds

[11] https://smt.asmpt.com/en/products/storage-solutions/material-tower/

[12] https://smt.asmpt.com/en/news-center/case-studies/faster-and-smarter-with-more-transparency-and-flexibility/

[13] https://www.infismash.com/smt-reel-storage/

[14] https://www.reddit.com/r/AskElectronics/comments/11mspyt/storing_smt_reels/

[15] https://www.ipc.org/system/files/technical_resource/E6&S30_02.pdf

[16] https://wirerackshelving.en.made-in-china.com/product/CZItEHrMsYGT/China-SMT-Component-Reel-Shelving-with-Wheels.html

[17] https://www.smthelp.com/smt-reel-storage-solution.html

[18] https://www.electronicsonline.net.au/content/assembly/sponsored/-smart-factory-smt-component-management-solutions-1034597184

[19] https://www.smthelp.com/sir7000b-intelligent-smt-reel-rack-7inch.html

[20] https://inovaxe.com/solutions/