Content Menu

● Introduction to Mylar SMT Stencils

>> Advantages of Mylar SMT Stencils

● Comparison with Traditional Materials

>> Stainless Steel Stencils

>> Kapton Stencils

● Applications of Mylar SMT Stencils

● Future Prospects and Challenges

>> Advancements in Stencil Technology

>> Sustainability Considerations

● Impact of SMT Stencils on PCB Prototyping

>> Role of Laser-Cut Stencils

>> Trends in SMT Industry

● Challenges and Opportunities

>> Material Selection for SMT Stencils

● Conclusion

● FAQs

>> 1. What are the primary advantages of using Mylar SMT stencils?

>> 2. How do Mylar stencils compare to stainless steel stencils in terms of durability?

>> 3. What is the temperature stability of Mylar compared to Kapton?

>> 4. What technology is used to cut Mylar stencils for precise aperture walls?

>> 5. Are Mylar stencils suitable for high-volume PCB manufacturing?

● Citations:

In the realm of Surface Mount Technology (SMT), stencils play a crucial role in applying solder paste to printed circuit boards (PCBs). Among various stencil materials, Mylar has emerged as a popular choice for prototype PCB assembly, especially among students and hobbyists. This article delves into the reasons why Mylar SMT stencils are preferred over traditional materials like stainless steel, highlighting their advantages, applications, and future prospects.

Introduction to Mylar SMT Stencils

Mylar, a type of polyester film made from stretched polyethylene terephthalate, is renowned for its high tensile strength and flexibility. These properties make it an ideal material for creating prototype stencils. Mylar stencils are particularly favored for their cost-effectiveness and ease of use in low-volume manufacturing and prototyping environments.

Advantages of Mylar SMT Stencils

1. Cost-Effectiveness: Mylar stencils are significantly cheaper than traditional stainless steel stencils. For instance, a Mylar stencil can cost around $50 for the first 25 square inches, with additional square inches priced at $1.85 each. This affordability makes them accessible to individuals with limited budgets, such as students and hobbyists.

2. Flexibility: Mylar is flexible and can be easily cut with laser technology, allowing for precise aperture walls that enhance solder paste release. This flexibility also enables Mylar stencils to be used on irregular surfaces, although this is less common in PCB assembly.

3. Ease of Use: Mylar stencils are straightforward to work with, especially in small-scale projects. They do not require specialized equipment for handling, unlike some metal stencils that need frames for support.

4. Environmental Stability: While Mylar's temperature range is limited compared to Kapton, it still offers sufficient stability for most PCB assembly processes, operating effectively between -70°C to +180°C.

Comparison with Traditional Materials

Stainless Steel Stencils

Stainless steel stencils, particularly those made from high-nickel content materials like PHD stainless steel, are known for their durability and dimensional stability. They provide smoother aperture walls, which improve solder paste release and reduce paste residue. However, they are more expensive and less flexible than Mylar, making them less suitable for small-scale or prototype projects.

Kapton Stencils

Kapton, a polyimide film, offers superior temperature stability compared to Mylar, maintaining its properties from -273°C to +400°C. While Kapton is more reliable in extreme environments, it shares Mylar's cost-effectiveness and is also used in flexible printed circuits. However, Kapton stencils are not as widely used for PCB prototyping as Mylar due to slightly higher costs and less availability.

Applications of Mylar SMT Stencils

Mylar SMT stencils are primarily used in prototype PCB assembly and low-volume manufacturing. They are ideal for:

- Educational Projects: Students often use Mylar stencils for hands-on learning experiences due to their affordability and ease of use.

- Hobbyist Projects: Hobbyists prefer Mylar for small-scale electronics projects, where cost and simplicity are key considerations.

- Rapid Prototyping: Mylar stencils facilitate quick turnaround times, allowing for rapid iteration and testing of PCB designs.

Future Prospects and Challenges

As technology advances, the demand for cost-effective and efficient stencil materials is expected to grow. Mylar stencils will likely continue to play a significant role in the prototyping phase of PCB development. However, challenges such as improving durability and precision may drive innovation in Mylar stencil manufacturing.

Advancements in Stencil Technology

Recent advancements in laser cutting technology have significantly improved the precision and quality of Mylar stencils. UV laser cutting, in particular, offers smooth aperture walls, enhancing solder paste release and reducing the risk of smearing. Additionally, advancements in materials science may lead to the development of new, more durable materials that retain the cost-effectiveness of Mylar.

Sustainability Considerations

The electronics industry is increasingly focusing on sustainability, with efforts to reduce waste and environmental impact. Mylar stencils, being less resource-intensive than stainless steel, contribute to this goal by offering a more eco-friendly option for small-scale projects. However, further research is needed to develop fully biodegradable stencil materials that maintain performance standards.

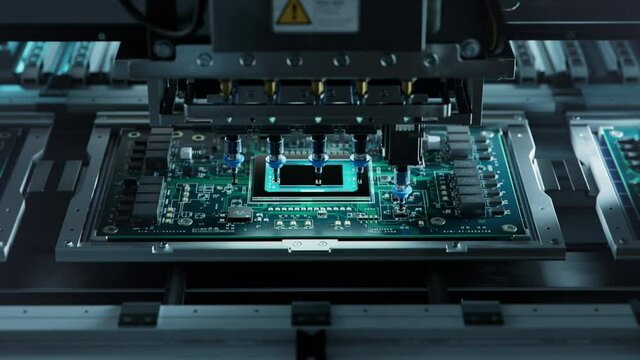

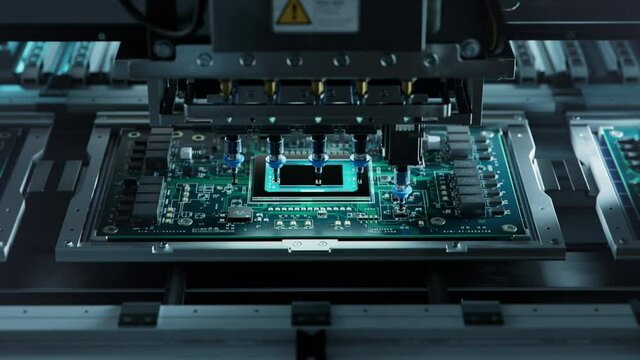

Impact of SMT Stencils on PCB Prototyping

SMT stencils have revolutionized PCB prototyping by providing a precise and efficient method for applying solder paste. This precision reduces errors such as bridging and tombstoning, common issues in manual soldering processes. Moreover, stencils enable the use of fine-pitch components, which are critical in modern electronics for miniaturization and performance enhancement.

Role of Laser-Cut Stencils

Laser-cut stencils, including those made from Mylar, offer superior precision compared to traditional methods like chemical etching. The high accuracy and speed of laser cutting make it ideal for rapid prototyping, where quick turnaround times are essential. However, laser cutting can sometimes introduce local deformations in dense aperture areas, requiring additional processing steps to ensure smooth aperture walls.

Trends in SMT Industry

The SMT industry is witnessing a trend towards miniaturization, with components like 0201 (0603 metrics) and 01005 (0402 metrics) becoming more common. This miniaturization requires stencils with finer pitches and higher precision, driving the demand for advanced laser cutting technologies and materials like Mylar that can accommodate these needs[6].

Challenges and Opportunities

Despite their advantages, Mylar stencils face challenges such as limited durability and precision compared to stainless steel. However, these limitations also present opportunities for innovation. For instance, advancements in laser technology are expected to improve the precision and speed of stencil cutting, making Mylar stencils even more viable for rapid prototyping[3][8].

Material Selection for SMT Stencils

The choice of material for SMT stencils depends on the specific requirements of the project. Mylar is ideal for low-cost, low-volume applications, while stainless steel is preferred for high-volume manufacturing due to its durability. Kapton offers superior temperature stability but is slightly more expensive than Mylar[4][5].

Conclusion

Mylar SMT stencils offer a compelling alternative to traditional materials like stainless steel for prototype PCB assembly. Their cost-effectiveness, flexibility, and ease of use make them an attractive choice for students, hobbyists, and small-scale manufacturers. While they may not match the durability of stainless steel, Mylar stencils provide sufficient quality for low-volume applications and are well-suited for rapid prototyping environments.

FAQs

1. What are the primary advantages of using Mylar SMT stencils?

Mylar stencils are cost-effective, flexible, and easy to use, making them ideal for prototype PCB assembly and low-volume manufacturing.

2. How do Mylar stencils compare to stainless steel stencils in terms of durability?

Mylar stencils have a shorter lifespan compared to stainless steel stencils, typically lasting up to 100 applications, whereas stainless steel stencils are more durable and long-lasting.

3. What is the temperature stability of Mylar compared to Kapton?

Mylar operates effectively between -70°C to +180°C, while Kapton maintains its properties from -273°C to +400°C, making Kapton more suitable for extreme environments.

4. What technology is used to cut Mylar stencils for precise aperture walls?

Mylar stencils are typically cut using laser technology, such as UV laser or CO2 laser, to achieve smooth aperture walls and enhance solder paste release.

5. Are Mylar stencils suitable for high-volume PCB manufacturing?

Mylar stencils are generally not recommended for high-volume manufacturing due to their limited durability and precision compared to stainless steel stencils.

Citations:

[1] https://www.pololu.com/product/446

[2] https://www.stencilsonline.com/mylar-stencil-material/

[3] https://www.latechlaser.com/news/future-trends-in-smt-stencil-laser-cutting-tec-78495992.html

[4] https://www.pcbunlimited.com/products/mylar-and-kapton-smt-stencils

[5] https://smtnet.com/library/files/upload/plastic-vs-metal-stencils.pdf

[6] https://blueringstencils.com/top-5-smt-industry-trends-for-2019/

[7] https://www.stencilsunlimited.com/t/smt-stencils

[8] https://fctsolder.com/wp-content/uploads/2017/08/123386-361848.smt-printing-challenges.pdf