Content Menu

● The Importance of Clean SMT Nozzles

● Benefits of Using an SMT Nozzle Cleaner

>> Enhanced Efficiency

>> Cost-Effectiveness

>> Improved Production Quality

>> Consistency in Performance

● Types of SMT Nozzle Cleaners

>> Ultrasonic Cleaners

>>> Advantages:

>>> Disadvantages:

>> High-Pressure Water Mist Cleaners

>>> Advantages:

>>> Disadvantages:

>> Combination Cleaners

>>> Advantages:

>>> Disadvantages:

● Selecting the Right SMT Nozzle Cleaner

>> Production Volume

>> Type of Components

>> Budget Constraints

>> Space Availability

● Best Practices for Using an SMT Nozzle Cleaner

● Conclusion

● FAQ

>> 1. What is an SMT nozzle cleaner?

>> 2. How often should I clean my SMT nozzles?

>> 3. Can I use regular cleaning solutions in my SMT nozzle cleaner?

>> 4. What are the advantages of automated SMT nozzle cleaners over manual methods?

>> 5. Are there any risks associated with using ultrasonic cleaners?

● Citations:

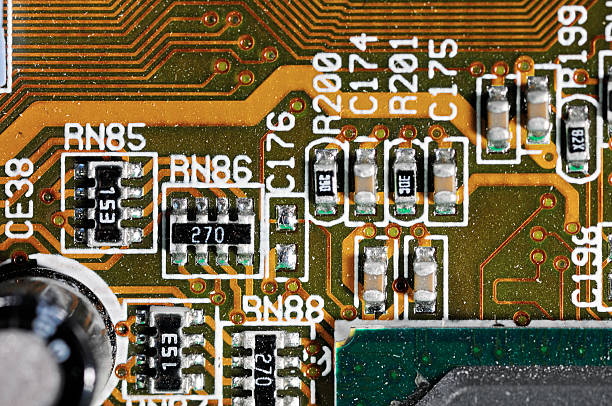

In the world of electronics manufacturing, Surface Mount Technology (SMT) has become a cornerstone for assembling printed circuit boards (PCBs). A critical component of this process is the SMT nozzle, which is responsible for picking and placing components with precision. However, maintaining the cleanliness of these nozzles is essential for optimal performance. This is where SMT nozzle cleaners come into play. In this article, we will explore the importance of using an SMT nozzle cleaner, its benefits, and how it can enhance efficiency in your production line.

The Importance of Clean SMT Nozzles

SMT nozzles are subjected to various contaminants during the assembly process, including solder paste, flux residues, and dust. Over time, these contaminants can lead to:

- Blockages: Clogged nozzles can cause misalignment during component placement.

- Reduced Lifespan: Contaminated nozzles wear out faster, increasing replacement costs.

- Increased Downtime: Manual cleaning methods are often time-consuming and can halt production.

To mitigate these issues, regular cleaning of SMT nozzles is crucial. This is where an SMT nozzle cleaner proves invaluable.

Benefits of Using an SMT Nozzle Cleaner

Enhanced Efficiency

Using an SMT nozzle cleaner significantly boosts the efficiency of the production process. Here's how:

- Automated Cleaning: Modern SMT nozzle cleaners automate the cleaning process, reducing the need for manual intervention. This not only saves time but also minimizes human error.

- Thorough Cleaning: These machines utilize advanced cleaning techniques such as high-pressure water mist or ultrasonic cleaning to ensure that no residue remains on the nozzles. This thoroughness leads to better component placement accuracy.

Cost-Effectiveness

Investing in an SMT nozzle cleaner can lead to substantial cost savings in the long run:

- Reduced Replacement Costs: By maintaining the cleanliness of nozzles, you extend their lifespan and reduce the frequency of replacements. Given that high-quality nozzles can be quite expensive, this represents significant savings.

- Lower Labor Costs: Automated cleaning systems eliminate the need for dedicated personnel to clean nozzles manually, allowing your workforce to focus on more critical tasks.

Improved Production Quality

The quality of your final product is directly linked to the performance of your SMT nozzles:

- Minimized Misplacement Errors: Clean nozzles ensure that components are picked and placed accurately, reducing defects in the assembly process.

- Higher Yield Rates: Improved accuracy leads to fewer product failures and higher yield rates, ultimately enhancing profitability.

Consistency in Performance

Another significant advantage of using an SMT nozzle cleaner is the consistency it brings to your production line:

- Uniform Cleaning Results: Automated systems provide consistent cleaning results across all nozzles, ensuring that each one performs at its best. This uniformity helps maintain a steady production flow and reduces variability in product quality.

- Predictable Maintenance Schedules: With a dedicated cleaning system in place, manufacturers can establish predictable maintenance schedules that align with production needs. This predictability allows for better planning and resource allocation.

Types of SMT Nozzle Cleaners

There are several types of SMT nozzle cleaners available on the market today, each designed to address specific cleaning needs:

Ultrasonic Cleaners

Ultrasonic cleaners use high-frequency sound waves to create microscopic bubbles in a cleaning solution. When these bubbles collapse, they produce a scrubbing action that effectively removes contaminants from the surface of the nozzles.

Advantages:

- Effective for intricate designs and hard-to-reach areas.

- Can accommodate various nozzle sizes.

Disadvantages:

- May not be suitable for all materials due to potential damage from ultrasonic waves.

High-Pressure Water Mist Cleaners

These machines use high-pressure water mist combined with specialized cleaning agents to remove dirt and residues from nozzles without causing damage.

Advantages:

- Environmentally friendly as they often use deionized water.

- Quick cleaning cycles enhance productivity.

Disadvantages:

- Requires careful calibration to avoid damaging sensitive components.

Combination Cleaners

Some advanced models combine ultrasonic cleaning with high-pressure water mist technology for a comprehensive cleaning solution.

Advantages:

- Provides thorough cleaning across different nozzle types.

- Offers flexibility in operations by combining multiple cleaning methods.

Disadvantages:

- Higher initial investment compared to single-method cleaners.

Selecting the Right SMT Nozzle Cleaner

When choosing an SMT nozzle cleaner for your manufacturing setup, consider several factors:

Production Volume

Evaluate your production volume and frequency of nozzle usage. High-volume operations may benefit more from automated systems that can handle frequent cleanings without downtime.

Type of Components

The type of components being placed can influence your choice of cleaner. For example, if you're working with smaller or more delicate components, an ultrasonic cleaner might be more appropriate due to its gentle yet effective cleaning action.

Budget Constraints

Consider your budget when selecting a cleaner. While automated systems may have higher upfront costs, they often lead to long-term savings through reduced labor and replacement costs.

Space Availability

Ensure that you have adequate space for the cleaner within your facility. Some advanced models may require more room due to their size or additional features.

Best Practices for Using an SMT Nozzle Cleaner

To maximize the benefits of your SMT nozzle cleaner, consider implementing these best practices:

1. Regular Maintenance: Ensure that your cleaning machine is regularly serviced and maintained according to manufacturer guidelines to prevent breakdowns and inefficiencies.

2. Proper Training: Train staff on how to operate the machine effectively and safely. Understanding how to utilize all features will enhance productivity.

3. Monitor Cleaning Cycles: Keep track of how often you clean your nozzles based on production volume and contamination levels. Adjust cleaning schedules as necessary to maintain optimal performance.

4. Use Recommended Cleaning Solutions: Always use cleaning agents that are recommended by the manufacturer of your nozzle cleaner to avoid damage and ensure effective cleaning.

5. Inspect Nozzles Post-Cleaning: After cleaning, inspect nozzles for any remaining contaminants or signs of wear before reinstallation.

6. Document Cleaning Procedures: Maintain records of cleaning procedures and results to identify trends over time. This documentation can help in troubleshooting issues related to component placement or production quality.

7. Integrate with Production Workflow: Consider integrating your cleaning processes into your overall production workflow. Scheduling cleanings during planned downtimes or breaks can help minimize disruptions while ensuring that equipment remains in top condition.

Conclusion

Choosing an SMT nozzle cleaner is not just about maintaining equipment; it's a strategic decision that impacts overall production efficiency, cost-effectiveness, and product quality. By investing in automated and effective cleaning solutions, manufacturers can ensure their SMT processes run smoothly while minimizing downtime and maximizing profitability. The benefits far outweigh the costs associated with acquiring such machines, making them essential tools in modern electronics manufacturing.

In summary, clean SMT nozzles lead to improved efficiency through enhanced accuracy in component placement, reduced downtime due to fewer blockages or misalignments, and extended lifespan for expensive equipment. As technology continues to evolve within the electronics industry, adopting advanced solutions like SMT nozzle cleaners will be crucial for staying competitive in a fast-paced market environment.

FAQ

1. What is an SMT nozzle cleaner?

An SMT nozzle cleaner is a specialized machine designed to clean pick-and-place machine nozzles used in surface mount technology processes. It helps remove contaminants that can affect performance and accuracy during component placement.

2. How often should I clean my SMT nozzles?

The frequency of cleaning depends on production volume and contamination levels. Generally, it's advisable to clean nozzles after every production run or when you notice a decline in placement accuracy.

3. Can I use regular cleaning solutions in my SMT nozzle cleaner?

It is recommended to use only those cleaning solutions specified by the manufacturer of your nozzle cleaner to prevent damage and ensure effective cleaning results.

4. What are the advantages of automated SMT nozzle cleaners over manual methods?

Automated cleaners save time by reducing manual labor requirements, provide thorough cleaning results that minimize misplacement errors, and lower overall operational costs due to reduced labor needs and extended nozzle lifespan.

5. Are there any risks associated with using ultrasonic cleaners?

Yes, ultrasonic cleaners may not be suitable for all types of nozzles due to potential damage from ultrasonic waves if not used correctly; always consult manufacturer guidelines before use.

Citations:

[1] https://silmantech.com/why-do-you-need-automatic-nozzle-cleaning-machine/

[2] https://www.obsmt.com/product/smt-nozzle-cleaning-machine/

[3] https://smtnet.com/parts/index.cfm?fuseaction=view_item&company_id=51925&item_id=155877

[4] https://silmantech.com/3-common-methods-for-cleaning-smt-nozzles/

[5] https://smtnova.com/practices-for-cleaning-smt-nozzles/

[6] https://www.uic.com/universal-instruments-new-smt-nozzle-cleaning-solution/

[7] https://www.dry-fog.com/en/projects-technology/technical-report/hum-smt-001/

[8] https://www.odm-technology.com/mobile/prod/auto-smt-nozzle-cleaner

[9] https://smt.fuji.co.jp/en/product/smartnozzle

[10] https://www.gssmt-parts.com/how-to-clean-smt-nozzle.html