Content Menu

● Understanding the Role of the SMT Stencil Squeegee

● How the SMT Squeegee Affects Print Quality

>> 1. Squeegee Material and Hardness

>> 2. Squeegee Pressure

>> 3. Squeegee Speed

>> 4. Squeegee Blade Thickness and Angle

>> 5. Squeegee System Design

● Common Defects Related to Squeegee Issues

● Optimizing SMT Squeegee for Better Print Quality

● Advanced Techniques for SMT Squeegee Optimization

>> 1. Temperature Control of the Squeegee

>> 2. Squeegee Blade Maintenance and Replacement

>> 3. Using Dual Squeegee Systems

>> 4. Adaptive Squeegee Pressure Control

● Case Studies: Impact of Squeegee Parameters on Print Quality

>> Case Study 1: Effect of Squeegee Pressure on Fine Pitch Printing

>> Case Study 2: Squeegee Speed Optimization for High-Volume Production

● Troubleshooting Common Squeegee-Related Print Defects

>> 1. Insufficient Paste Deposition

>> 2. Excessive Paste Deposition

>> 3. Solder Bridging

>> 4. Stencil Damage

● Future Trends in SMT Squeegee Technology

● Summary

● Conclusion

● Frequently Asked Questions (FAQ)

>> 1. What is the best squeegee material for SMT stencil printing?

>> 2. How does squeegee pressure affect solder paste deposition?

>> 3. Why is squeegee speed important in SMT printing?

>> 4. Can squeegee blade angle impact print quality?

>> 5. How often should the stencil and squeegee be cleaned?

In Surface Mount Technology (SMT), the quality of solder paste printing directly impacts the reliability and performance of electronic assemblies. One critical yet often overlooked factor influencing print quality is the SMT stencil squeegee. This article explores why your SMT squeegee affects print quality, the mechanisms behind it, and how to optimize squeegee parameters to achieve the best results.

Understanding the Role of the SMT Stencil Squeegee

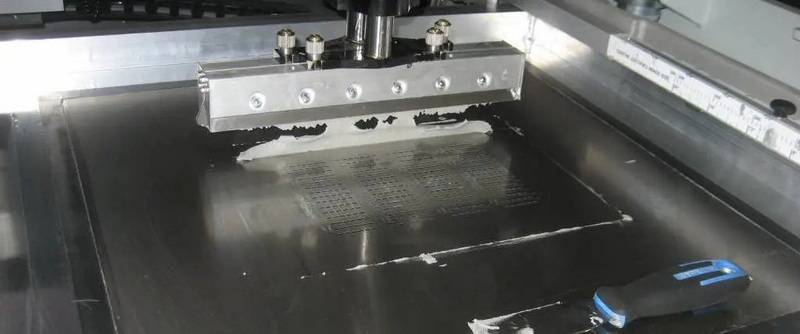

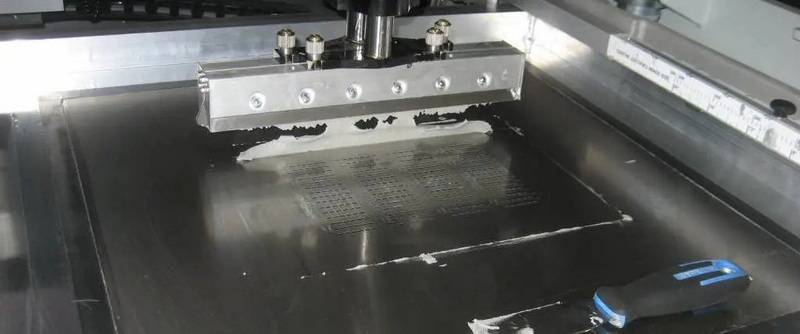

The squeegee in SMT printing machines plays a vital role by pushing solder paste across the stencil and forcing it into the stencil apertures, which correspond to the pads on the Printed Circuit Board (PCB). The squeegee ensures a uniform layer of solder paste is deposited on the PCB, which is essential for proper component soldering during reflow.

- The squeegee presses the stencil to maintain contact with the PCB.

- It rolls the solder paste forward, filling the stencil openings.

- When the stencil lifts off, the solder paste remains on the PCB pads at the correct thickness.

How the SMT Squeegee Affects Print Quality

1. Squeegee Material and Hardness

The squeegee blade can be made from rubber or metal, each with different hardness and friction characteristics.

- Rubber squeegees are softer and may embed into stencil apertures under high pressure, causing uneven paste deposition and defects like printing depressions.

- Metal squeegees are harder, more wear-resistant, and coated to reduce friction, allowing better paste transfer and eliminating unevenness.

2. Squeegee Pressure

The pressure applied by the squeegee affects how well solder paste fills the stencil apertures.

- Too little pressure results in incomplete filling, causing insufficient solder deposits and open joints.

- Excessive pressure can damage the stencil, cause coining (deformation), and lead to excessive paste deposition or bridging defects.

3. Squeegee Speed

The speed at which the squeegee moves influences the flow and distribution of solder paste.

- A high squeegee speed reduces the time for solder paste to roll into apertures, causing insufficient fills.

- Too slow speed may lead to excessive paste deposits and smearing.

4. Squeegee Blade Thickness and Angle

- Thicker blades and improper blade attack angles can reduce print quality by affecting paste transfer efficiency.

- Optimal blade angles (typically 60° to 80°) improve paste filling and reduce defects.

5. Squeegee System Design

Modern SMT printers use intelligent squeegee systems with precise pressure control, dual motors, and adaptive platforms to optimize print quality.

- Closed squeegee technology improves paste utilization and reduces oxidation.

- Automated systems ensure consistent pressure and speed, enhancing print repeatability.

Common Defects Related to Squeegee Issues

- Insufficient solder paste: Caused by low pressure, high speed, or stencil clogging.

- Excessive solder paste: Due to too much pressure or slow squeegee speed.

- Solder bridging: When paste spreads excessively between pads.

- Stencil damage: From excessive pressure or wrong squeegee material.

- Uneven paste deposits: Due to squeegee blade wear or improper angle.

Optimizing SMT Squeegee for Better Print Quality

To improve print quality, consider the following:

- Use the appropriate squeegee material (metal for fine pitch, rubber for general use).

- Adjust squeegee pressure to ensure full aperture filling without damaging the stencil.

- Set squeegee speed within optimal ranges (e.g., 35-95 mm/s).

- Maintain correct blade angle (60°-80°) for efficient paste transfer.

- Regularly clean the stencil and squeegee to prevent clogging and residue buildup.

- Employ advanced squeegee systems with precise control and adaptive features.

Advanced Techniques for SMT Squeegee Optimization

1. Temperature Control of the Squeegee

Maintaining an optimal temperature for the squeegee blade can influence solder paste viscosity and print quality. Some advanced SMT printers incorporate heated squeegee blades to keep the solder paste at a consistent temperature, preventing premature drying or hardening during printing. This helps maintain paste flow characteristics and reduces defects caused by paste drying on the stencil or blade.

2. Squeegee Blade Maintenance and Replacement

Regular inspection and timely replacement of squeegee blades are crucial. Worn or damaged blades can cause inconsistent paste deposition and defects such as smearing or uneven prints. Establishing a maintenance schedule based on production volume and paste type helps maintain print quality and reduces downtime.

3. Using Dual Squeegee Systems

Dual squeegee systems use two blades in sequence to improve paste transfer and reduce defects. The first blade spreads the paste across the stencil, while the second blade ensures uniform thickness and cleans excess paste from the stencil surface. This method enhances print consistency, especially in high-speed or high-volume production environments.

4. Adaptive Squeegee Pressure Control

Modern SMT printers feature adaptive pressure control systems that adjust squeegee pressure in real-time based on feedback from sensors monitoring paste deposition and stencil condition. This technology compensates for stencil wear, paste viscosity changes, and other variables to maintain consistent print quality throughout production runs.

Case Studies: Impact of Squeegee Parameters on Print Quality

Case Study 1: Effect of Squeegee Pressure on Fine Pitch Printing

A manufacturer experienced frequent solder bridging on a 0.4 mm pitch PCB. By reducing squeegee pressure from 1.5 kg to 1.0 kg, the bridging defects decreased by 70%, improving yield significantly. This adjustment prevented excessive paste from being forced between fine-pitch pads, demonstrating the importance of pressure control for delicate stencil apertures.

Case Study 2: Squeegee Speed Optimization for High-Volume Production

In a high-volume production line, increasing squeegee speed from 40 mm/s to 70 mm/s reduced cycle time by 30% without compromising print quality, thanks to optimized paste formulation and stencil design. This balance between speed and paste flow ensured efficient printing while maintaining aperture fill integrity.

Troubleshooting Common Squeegee-Related Print Defects

1. Insufficient Paste Deposition

- Check squeegee pressure and increase if too low.

- Inspect stencil for clogging or damage.

- Verify paste viscosity and temperature to ensure proper flow.

2. Excessive Paste Deposition

- Reduce squeegee pressure.

- Increase squeegee speed.

- Check for worn or damaged squeegee blades that may cause uneven paste distribution.

3. Solder Bridging

- Adjust squeegee pressure and speed to reduce excess paste.

- Ensure stencil apertures are clean and correctly sized.

- Use metal squeegees for better control on fine-pitch boards.

4. Stencil Damage

- Avoid excessive squeegee pressure.

- Use appropriate squeegee material for the application.

- Regularly inspect and replace worn stencils to prevent damage and defects.

Future Trends in SMT Squeegee Technology

- Integration of AI and machine learning for predictive maintenance and real-time process optimization is becoming more prevalent. These systems can automatically adjust squeegee parameters based on historical data and live feedback.

- Development of new squeegee materials with enhanced durability and reduced friction will extend blade life and improve paste transfer efficiency.

- Enhanced sensor technology enables more precise control of pressure, speed, and temperature, ensuring consistent print quality even in complex production environments.

Summary

Optimizing the SMT stencil squeegee involves a combination of material selection, mechanical settings, maintenance, and advanced technologies. By understanding and controlling these factors, manufacturers can significantly improve solder paste print quality, reduce defects, and enhance overall production efficiency. The squeegee is not just a simple blade but a sophisticated tool that, when properly managed, ensures the success of the SMT assembly process.

Conclusion

The SMT stencil squeegee is a critical factor that significantly affects solder paste print quality. Its material, pressure, speed, thickness, and angle all influence how solder paste is transferred onto the PCB. Optimizing these parameters and using modern squeegee systems can reduce defects such as insufficient fills, bridging, and stencil damage, ultimately improving the reliability of SMT assemblies. Continuous monitoring, maintenance, and adoption of advanced squeegee technologies are key to maintaining high-quality SMT printing in today's demanding electronics manufacturing landscape.

Frequently Asked Questions (FAQ)

1. What is the best squeegee material for SMT stencil printing?

Answer: Metal squeegees are preferred for fine pitch and high precision printing due to their hardness and wear resistance, while rubber squeegees are used for general applications but may cause defects under high pressure.

2. How does squeegee pressure affect solder paste deposition?

Answer: Proper pressure ensures full filling of stencil apertures. Too low pressure causes insufficient paste, while too high pressure can damage the stencil and cause excessive paste deposition.

3. Why is squeegee speed important in SMT printing?

Answer: Squeegee speed controls the time solder paste has to fill stencil apertures. High speed can cause insufficient fills, and slow speed may lead to excessive paste and smearing.

4. Can squeegee blade angle impact print quality?

Answer: Yes, blade angle affects the paste rolling and filling efficiency. Angles between 60° and 80° are typically optimal for good print quality.

5. How often should the stencil and squeegee be cleaned?

Answer: Regular cleaning during production (e.g., every half hour) prevents paste buildup and clogging, maintaining consistent print quality.