Content Menu

● What is an SMT Reflow Oven?

● The Role of SMT Reflow Oven in PCB Manufacturing

>> Precise Temperature Control and Uniform Heating

>> Ensuring Reliable Solder Joints

>> Supporting Lead-Free Soldering

>> High Throughput and Automation

● How Does an SMT Reflow Oven Work?

● Detailed Explanation of Temperature Zones in SMT Reflow Ovens

● Types of SMT Reflow Ovens

>> Infrared (IR) Reflow Ovens

>> Convection Reflow Ovens

>> Vapor Phase Reflow Ovens

>> Vacuum Reflow Ovens

● Advantages of Using SMT Reflow Oven for PCB Manufacturing

● Understanding Solder Paste and Flux in SMT Reflow Process

● Importance of Process Control and Monitoring

● Impact of SMT Reflow Oven on PCB Design and Manufacturing

● Environmental and Safety Considerations

● Innovations and Future Trends in SMT Reflow Oven Technology

● Troubleshooting Common Issues in SMT Reflow Ovens

● Quality Assurance and Testing in SMT Reflow Soldering

● Applications of SMT Reflow Ovens Across Industries

● Future Challenges and Opportunities for SMT Reflow Ovens

● Conclusion

● FAQ

>> 1. What is the main function of an SMT reflow oven in PCB manufacturing?

>> 2. How many temperature zones does a typical SMT reflow oven have?

>> 3. Why is nitrogen sometimes used in SMT reflow ovens?

>> 4. What are the advantages of vacuum SMT reflow ovens?

>> 5. How can reflow oven faults affect PCB assembly quality?

In the rapidly evolving electronics manufacturing industry, the demand for high-quality, reliable, and efficient printed circuit board (PCB) assembly has never been greater. Central to this process is the Surface Mount Technology (SMT) reflow oven, a critical piece of equipment that ensures surface mount components are securely soldered to PCBs. This article explores why the SMT reflow oven for PCB manufacturing is indispensable, detailing its operation, types, advantages, and impact on production quality and efficiency.

What is an SMT Reflow Oven?

An SMT reflow oven is a specialized machine designed to solder surface mount devices (SMDs) onto PCBs by precisely heating the solder paste applied to the board until it melts and forms strong, reliable joints. Unlike traditional through-hole technology, SMT places components directly on the PCB surface, enabling higher circuit density and more compact designs.

The reflow oven controls the temperature profile of the PCB assembly through multiple zones, ensuring that the solder paste transitions through critical phases-preheating, soaking, reflow, and cooling-without damaging components or compromising joint quality.

The Role of SMT Reflow Oven in PCB Manufacturing

Precise Temperature Control and Uniform Heating

The SMT reflow oven provides a controlled thermal environment, essential for melting solder paste uniformly across the PCB. It uses various heat transfer methods such as conduction, convection, and radiation to maintain consistent temperatures throughout the board, preventing defects like cold joints or overheating.

Ensuring Reliable Solder Joints

The oven's temperature profile is carefully programmed to activate the flux in the solder paste, remove oxides, and melt the solder alloy at the correct temperature. This process creates strong metallurgical bonds between component leads and PCB pads, which are critical for electrical continuity and mechanical stability.

Supporting Lead-Free Soldering

With environmental regulations such as RoHS mandating lead-free solder, SMT reflow ovens must accommodate higher melting points (217-220°C for lead-free solder) while protecting sensitive components. The oven's precise temperature zones and controlled heating rates allow manufacturers to meet these requirements effectively.

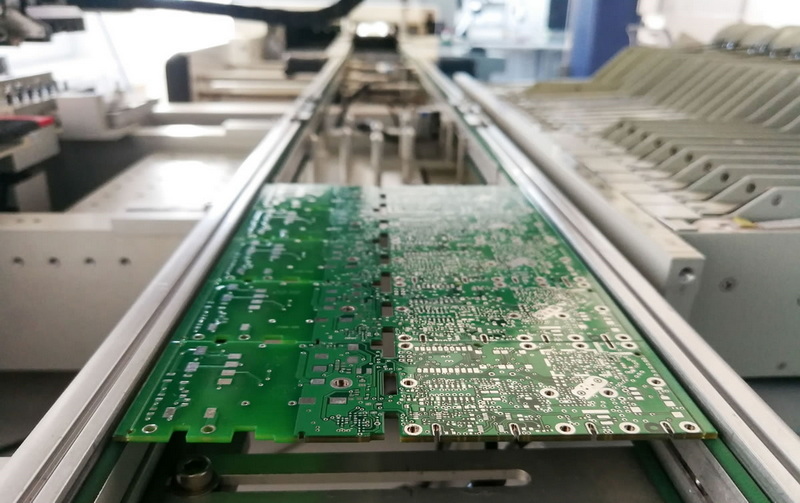

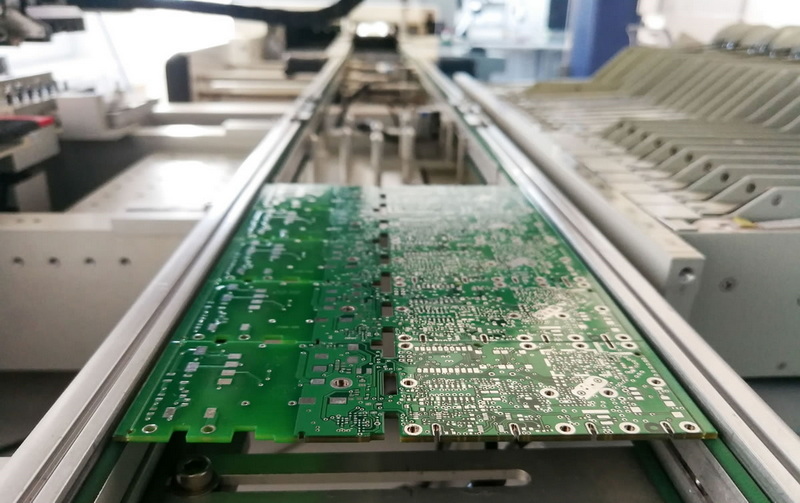

High Throughput and Automation

SMT reflow ovens can process multiple PCBs simultaneously, significantly increasing production throughput. Automation reduces human error and labor costs, making the manufacturing process faster and more consistent.

How Does an SMT Reflow Oven Work?

The reflow soldering process inside the oven typically involves four stages:

1. Preheating: Gradual temperature increase to avoid thermal shock and activate the flux in the solder paste.

2. Soaking: Holding the PCB at a steady temperature to ensure uniform heat distribution and flux activity.

3. Reflow: Heating to the solder's melting point (peak temperature zone) to melt the solder paste and form joints.

4. Cooling: Controlled cooling to solidify solder joints, preventing thermal stress and ensuring mechanical strength.

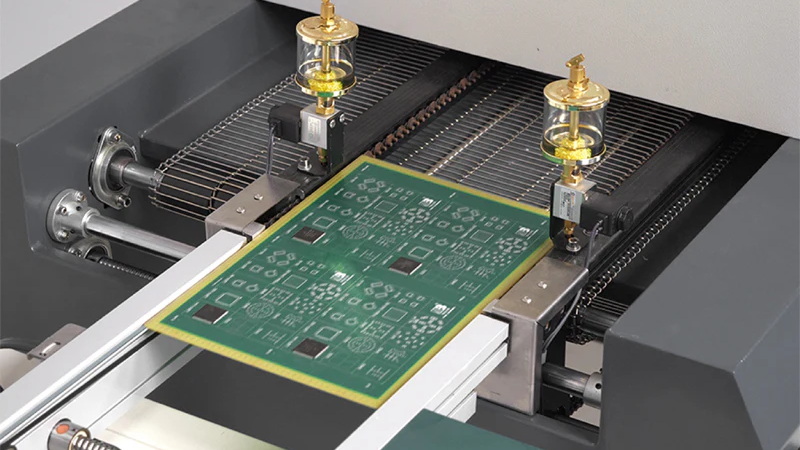

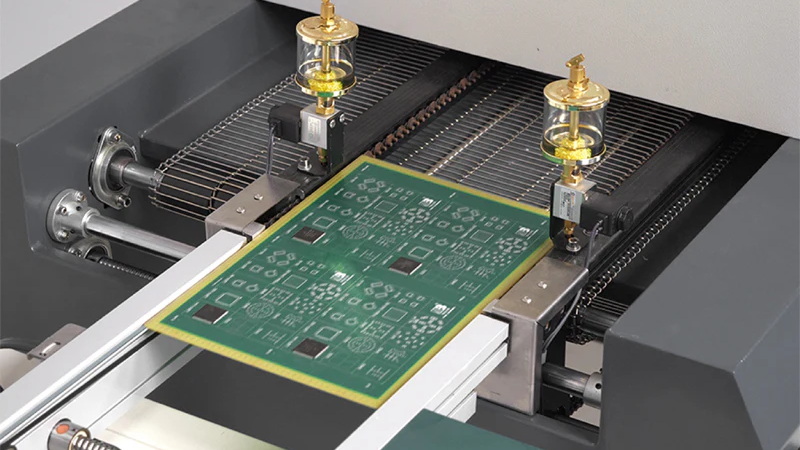

The oven usually contains multiple independently controlled temperature zones (3 to 10 or more), allowing fine-tuning of the thermal profile to match specific PCB and component requirements.

Detailed Explanation of Temperature Zones in SMT Reflow Ovens

The temperature zones in an SMT reflow oven are critical to the success of the soldering process. Each zone has a specific function:

- Preheat Zone: This zone gradually raises the temperature of the PCB and components to prevent thermal shock. It activates the flux in the solder paste, which helps clean the surfaces to be soldered.

- Soak Zone: The temperature is held steady to allow the flux to remove oxides and prepare the solder paste for melting. This zone ensures uniform temperature distribution across the PCB.

- Reflow Zone: The temperature peaks here, reaching the melting point of the solder alloy. The solder paste liquefies and forms metallurgical bonds between the component leads and PCB pads.

- Cooling Zone: The PCB is cooled at a controlled rate to solidify the solder joints and prevent thermal stress that could cause cracks or weak joints.

Understanding and controlling these zones precisely is essential for high-quality soldering.

Types of SMT Reflow Ovens

Infrared (IR) Reflow Ovens

Use infrared radiation to heat PCBs quickly and directly. They are suitable for certain applications but may have less uniform heating compared to convection ovens.

Convection Reflow Ovens

Employ heated air circulated by fans to distribute heat evenly across the PCB surface. This method provides superior temperature uniformity and is widely used in the industry.

Vapor Phase Reflow Ovens

Use a vaporized heat transfer fluid that condenses on the PCB, transferring heat efficiently and uniformly. This method offers precise temperature control and reduces oxidation.

Vacuum Reflow Ovens

Operate in a low-pressure environment, removing air bubbles and contaminants from solder joints. Vacuum ovens improve solder joint reliability and reduce defects such as voids and solder balls. They also provide uniform heating and reduce oxidation.

Advantages of Using SMT Reflow Oven for PCB Manufacturing

- High Precision: Ensures consistent and repeatable soldering quality with minimal defects.

- Improved Reliability: Produces strong solder joints critical for device durability.

- Increased Production Efficiency: Capable of handling large volumes with automated processes.

- Compatibility with Lead-Free Solder: Supports environmental compliance without compromising quality.

- Reduced Rework and Scrap: Minimizes defects such as cold joints, solder bridging, and solder balls.

- Enhanced Thermal Control: Multiple zones allow tailored temperature profiles for complex PCBs.

Understanding Solder Paste and Flux in SMT Reflow Process

Solder paste is a mixture of powdered solder alloy and flux, which plays a crucial role in the reflow soldering process. The flux helps clean the metal surfaces by removing oxides and contaminants, ensuring a strong metallurgical bond during soldering. The quality and type of solder paste directly affect the reliability of the solder joints.

Flux also prevents oxidation during heating and improves the wetting properties of the molten solder. Different types of fluxes are used depending on the application, including no-clean flux, water-soluble flux, and rosin-based flux.

Importance of Process Control and Monitoring

Maintaining strict control over the reflow process parameters is vital for consistent quality. This includes monitoring temperature profiles, conveyor speed, and atmosphere inside the oven. Advanced ovens are equipped with sensors and software to log data and alert operators to deviations.

Process control helps in minimizing defects such as tombstoning, solder balls, and insufficient wetting. It also ensures compliance with industry standards and customer specifications.

Impact of SMT Reflow Oven on PCB Design and Manufacturing

The use of SMT reflow ovens has influenced PCB design significantly. Designers can now place components more densely and use smaller components, which leads to more compact and lightweight electronic devices. The precision of reflow ovens allows for fine-pitch components and complex multilayer boards.

From a manufacturing perspective, reflow ovens enable high-speed production lines with minimal manual intervention. This automation reduces labor costs and increases consistency and repeatability in soldering quality.

Environmental and Safety Considerations

Modern SMT reflow ovens are designed with environmental and safety standards in mind. Many ovens incorporate features to reduce energy consumption, such as improved insulation and efficient heating elements. Additionally, ovens often include filtration systems to capture fumes and particulates generated during soldering, protecting workers and the environment.

Compliance with regulations like RoHS (Restriction of Hazardous Substances) has driven the adoption of lead-free soldering, which requires precise temperature control to avoid damaging components.

Innovations and Future Trends in SMT Reflow Oven Technology

The SMT reflow oven industry continues to evolve with innovations such as:

- Advanced Temperature Profiling: Using real-time sensors and AI algorithms to optimize the thermal profile dynamically for each PCB.

- Nitrogen Atmosphere Ovens: Increasingly common to reduce oxidation and improve solder joint quality.

- Energy-Efficient Designs: Incorporating renewable energy sources and better heat recovery systems.

- Integration with Industry 4.0: Smart ovens connected to manufacturing execution systems (MES) for better process control and traceability.

These advancements aim to improve quality, reduce costs, and enhance sustainability.

Troubleshooting Common Issues in SMT Reflow Ovens

Despite their sophistication, SMT reflow ovens can encounter issues such as:

- Temperature Inconsistencies: Caused by sensor failures or heating element degradation.

- Conveyor Problems: Misalignment or speed variations can affect soldering quality.

- Flux Residue Build-up: Leading to contamination and defects.

- Component Damage: Due to incorrect temperature profiles or thermal shock.

Regular maintenance, calibration, and operator training are essential to mitigate these problems.

Quality Assurance and Testing in SMT Reflow Soldering

After the reflow soldering process, quality assurance is critical to ensure the integrity and reliability of the PCB assembly. Various inspection and testing methods are employed:

- Automated Optical Inspection (AOI): Uses cameras to detect solder joint defects, component misalignment, and missing parts.

- X-ray Inspection: Identifies hidden defects such as voids, solder bridges, and insufficient solder in BGA and other complex packages.

- Functional Testing: Verifies the electrical performance of the assembled PCB.

Implementing rigorous quality control measures helps in early detection of defects, reducing rework and improving overall product reliability.

Applications of SMT Reflow Ovens Across Industries

SMT reflow ovens are used in a wide range of industries due to their ability to produce reliable and high-quality PCBs:

- Consumer Electronics: Smartphones, tablets, and wearable devices rely heavily on SMT for compact and high-density PCB assemblies.

- Automotive: Advanced driver-assistance systems (ADAS), infotainment, and engine control units require robust solder joints for safety and durability.

- Aerospace and Defense: High-reliability PCBs for avionics and military equipment demand precise soldering and quality assurance.

- Medical Devices: SMT enables miniaturization and reliability in devices such as pacemakers and diagnostic equipment.

- Industrial Automation: Control systems and sensors benefit from the efficiency and consistency of SMT reflow soldering.

The versatility of SMT reflow ovens makes them indispensable in modern manufacturing.

Future Challenges and Opportunities for SMT Reflow Ovens

As electronic devices continue to evolve, SMT reflow ovens face new challenges and opportunities:

- Miniaturization: Smaller components require even more precise temperature control and handling.

- New Materials: Emerging solder alloys and substrates may require adapted thermal profiles.

- Sustainability: Reducing energy consumption and waste will be increasingly important.

- Integration with AI and IoT: Smart ovens that self-optimize and predict maintenance needs will enhance productivity.

Addressing these challenges will ensure SMT reflow ovens remain vital in electronics manufacturing.

Conclusion

The SMT reflow oven for PCB manufacturing is a cornerstone technology that enables the production of modern electronic devices with high reliability and efficiency. Its precise temperature control, adaptability to lead-free soldering, and compatibility with automated production lines make it indispensable in today's electronics industry. As technology advances, SMT reflow ovens will continue to evolve, driving innovation and quality in PCB assembly.

FAQ

1. What is the main function of an SMT reflow oven in PCB manufacturing?

An SMT reflow oven melts the solder paste applied to PCBs to form strong, reliable solder joints between surface mount components and the board, ensuring mechanical and electrical connections.

2. How many temperature zones does a typical SMT reflow oven have?

Most SMT reflow ovens have between 3 to 10 temperature zones, including preheat, soak, peak (reflow), and cooling zones, allowing precise control over the soldering process.

3. Why is nitrogen sometimes used in SMT reflow ovens?

Nitrogen creates an inert atmosphere that reduces oxidation during soldering, improves solder flow, and enhances the quality and reliability of solder joints, especially for sensitive components.

4. What are the advantages of vacuum SMT reflow ovens?

Vacuum reflow ovens eliminate air bubbles and contaminants in solder joints, provide uniform heating, reduce oxidation, and improve joint reliability, resulting in fewer defects and higher product quality.

5. How can reflow oven faults affect PCB assembly quality?

Faults such as blower fan failure, heater malfunction, or conveyor calibration drift cause uneven heating or improper temperature profiles, leading to solder defects like cold joints, solder bridging, or component damage, reducing yield.