Content Menu

● Introduction to SMT Stencil Tension

>> Importance of Stencil Tension

● Methods for Measuring Stencil Tension

● Impact of Stencil Tension on SMT Process

● Best Practices for Stencil Tension Measurement

● Advanced Stencil Technologies and Tensioning Systems

>> Nanocoatings for Enhanced Print Quality

>> Tensioning Systems for Consistent Results

● Challenges in Maintaining Optimal Stencil Tension

● Conclusion

● FAQ

>> 1. What is the typical range for acceptable stencil tension in SMT processes?

>> 2. How does stencil tension affect solder paste application?

>> 3. What tools are used to measure stencil tension?

>> 4. Why is regular tension checking important?

>> 5. How does the choice of stencil material affect tension and print quality?

● Citations:

Stencil tension measurement is a critical aspect of the Surface Mount Technology (SMT) process, playing a pivotal role in ensuring the quality and consistency of solder paste printing. In this article, we will delve into the importance of stencil tension measurement, its impact on the SMT process, and how it contributes to achieving high-yield manufacturing.

Introduction to SMT Stencil Tension

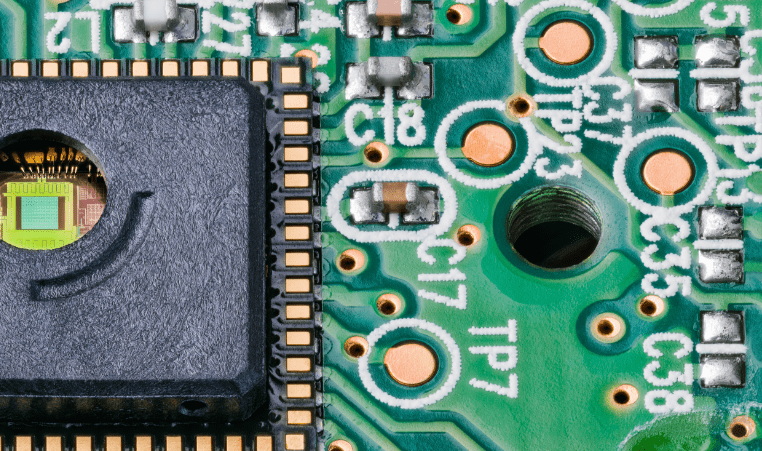

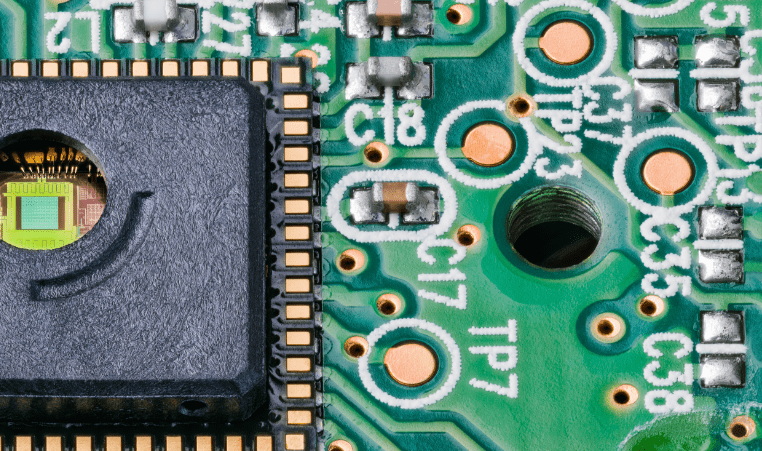

SMT stencils are used to apply solder paste onto printed circuit boards (PCBs) during the assembly process. The stencil's tension affects how evenly the solder paste is distributed, which in turn influences the quality of the solder joints. Proper tension ensures that the stencil remains flat and stable, preventing issues such as insufficient solder, bridging, or solder voids.

Importance of Stencil Tension

Stencil tension is crucial for several reasons:

1. Consistency in Solder Paste Application: Proper tension ensures that the solder paste is applied consistently across the PCB, which is essential for achieving reliable solder joints. Inconsistent tension can lead to variations in solder paste volume, affecting the quality of the final product.

2. Prevention of Soldering Defects: Soldering defects such as bridging or insufficient solder can be minimized by maintaining optimal stencil tension. These defects often result from uneven solder paste distribution, which can be caused by inadequate tension.

3. Enhanced Process Reliability: High tension stencils provide better aperture registration accuracy, which is vital for miniaturized components. This ensures that the solder paste is accurately aligned with the PCB pads, enhancing the overall reliability of the SMT process.

Methods for Measuring Stencil Tension

Measuring stencil tension involves using specialized tools to assess the tension across the stencil. Here are some common methods:

- Tension Meters: These devices measure the deflection of the stencil under a known force. A typical setup involves a long bar with a plunger gauge in the middle, where a known weight is applied to measure deflection. For instance, a stencil tension tester is placed 15-20 cm away from the edge of the stencil, with 5-8 points selected for testing, ensuring tension greater than 35-50 N/cm[1].

- Visual Inspection: Before using a tension meter, a visual inspection is necessary to check for any damage or irregularities on the stencil surface. This step helps identify potential issues that could affect measurement accuracy.

- Standard Tension Ranges: Acceptable tension ranges vary, but generally, stencils should have a tension between 30 to 50 N/cm. For more precise applications, tensions around 40 to 50 N/cm are recommended.

Impact of Stencil Tension on SMT Process

The impact of stencil tension on the SMT process is multifaceted:

- Foil Wear and Material Choice: The choice of stencil material (e.g., nickel or stainless steel) affects how tension impacts the printing process. Worn foils can lead to inconsistent solder paste volumes, while materials like stainless steel offer better durability and resistance to deformation[2]. For example, stainless steel stencils tend to maintain their tension better than nickel stencils, which can deform over time.

- Process Adjustments: Depending on the tension level, process adjustments may be necessary to optimize print quality. Higher tension can improve print consistency but may require adjustments in squeegee pressure or speed. For instance, increasing tension might necessitate reducing squeegee pressure to prevent excessive paste extrusion.

- Consistency Across Prints: Maintaining consistent tension ensures that each print cycle produces similar results, which is crucial for high-volume manufacturing where consistency is key.

Best Practices for Stencil Tension Measurement

To ensure accurate stencil tension measurement and maintain optimal SMT process control, follow these best practices:

- Regular Tension Checks: Stencil tension should be checked regularly, ideally before each use, to ensure it remains within the recommended range. This practice helps prevent defects caused by inconsistent tension.

- Use of Tension Meters: Invest in a reliable tension meter that can accurately measure tension across the stencil. Ensure the meter is calibrated correctly before use.

- Visual Inspection: Always perform a visual inspection before measuring tension to identify any potential issues that could affect measurement accuracy.

Advanced Stencil Technologies and Tensioning Systems

Recent advancements in stencil technologies include the use of nanocoatings and specialized tensioning systems. Nanocoatings improve print quality by reducing underwipe frequency and enhancing print definition[7]. Tensioning systems like the Alpha Tetra and Stencilman provide consistent tension across the stencil, ensuring precise aperture registration and improved print consistency[3].

Nanocoatings for Enhanced Print Quality

Nanocoatings are applied to the underside of the stencil to modify its surface tension. This creates a barrier around the apertures, preventing solder paste from spreading between them and reducing the occurrence of wet bridges[5]. The use of nanocoatings is particularly beneficial in high-yield processing environments where precision is paramount.

Tensioning Systems for Consistent Results

Mechanical tensioning systems offer superior consistency compared to traditional mesh-mounted stencils. These systems eliminate the need for mesh, providing a more stable and reliable tension across the stencil. This is especially important for miniaturized components where precise aperture registration is critical[2].

Challenges in Maintaining Optimal Stencil Tension

Maintaining optimal stencil tension can be challenging due to several factors:

- Foil Wear: Over time, stencil foils can wear out, leading to inconsistent tension and affecting print quality. Regular inspections and replacements are necessary to mitigate this issue.

- Material Selection: The choice of stencil material affects its durability and resistance to deformation. Stainless steel is generally preferred for its stability and resistance to wear.

- Environmental Factors: Temperature and humidity fluctuations can affect stencil tension and print quality. Maintaining a controlled environment is essential for consistent results.

Conclusion

Stencil tension measurement is a vital component of the SMT process, directly influencing the quality and reliability of solder paste printing. By understanding the importance of stencil tension and implementing best practices for measurement and maintenance, manufacturers can significantly improve the consistency and yield of their SMT operations. Regular tension checks, proper material selection, and the use of accurate measurement tools are essential for achieving optimal results.

FAQ

1. What is the typical range for acceptable stencil tension in SMT processes?

- The typical range for acceptable stencil tension is between 30 to 50 N/cm, with more precise applications often requiring tensions around 40 to 50 N/cm.

2. How does stencil tension affect solder paste application?

- Proper stencil tension ensures consistent solder paste application, which is crucial for achieving reliable solder joints. Inconsistent tension can lead to defects such as bridging or insufficient solder.

3. What tools are used to measure stencil tension?

- Stencil tension is typically measured using a tension meter, which assesses the deflection of the stencil under a known force. Visual inspections are also essential before measurement.

4. Why is regular tension checking important?

- Regular tension checks are important to ensure that the stencil remains within the recommended tension range, which is crucial for maintaining consistent print quality and preventing defects.

5. How does the choice of stencil material affect tension and print quality?

- The choice of stencil material (e.g., nickel vs. stainless steel) affects how tension impacts print quality. Stainless steel, for example, offers better durability and resistance to deformation compared to nickel.

Citations:

[1] https://silmantech.com/selection-tension-testing-and-cleaning-methods-of-smt-stencils/

[2] https://circuitsassembly.com/ca/editorial/menu-features/28733-stencil-printing-1802.html

[3] https://www.laserjob.com/fileadmin/images/Downloads/1_4_Frames_and_tensioning_systems.pdf

[4] https://fctsolder.com/wp-content/uploads/2017/08/123386-361848.smt-printing-challenges.pdf

[5] https://www.ipc.org/system/files/technical_resource/E5&S06_03.pdf

[6] https://www.circuitnet.com/experts/81809.html

[7] https://www.ipc.org/system/files/technical_resource/E38&S12-02%20-%20Chrys%20Shea.pdf

[8] https://fctsolder.com/wp-content/uploads/2017/08/2016-SMTAI-Step-stencil-paper.pdf