Content Menu

● What Is an SMT Stencil Envelope with a Henger?

● Why SMT Stencils Are Crucial in Electronics Production

● The Role of the SMT Stencil Envelope with a Henger in High-Quality Production

>> 1. Protection from Contamination and Damage

>> 2. Maintaining Stencil Flatness and Structural Integrity

>> 3. Enhancing Handling and Storage Efficiency

>> 4. Extending Stencil Lifespan and Reducing Costs

>> 5. Supporting High-Volume and High-Precision Production

● How the SMT Stencil Envelope with a Henger Fits into the SMT Assembly Process

● Benefits Summary of SMT Stencil Envelope with a Henger

● Conclusion

● FAQ

>> 1. What materials are typically used for SMT stencil envelopes and hengers?

>> 2. Can the SMT stencil envelope with a henger be used for all types of SMT stencils?

>> 3. How does the use of a henger prevent stencil warping?

>> 4. Does the envelope with henger system affect the cleaning process of SMT stencils?

>> 5. How does the SMT stencil envelope with a henger contribute to reducing production defects?

● Citations:

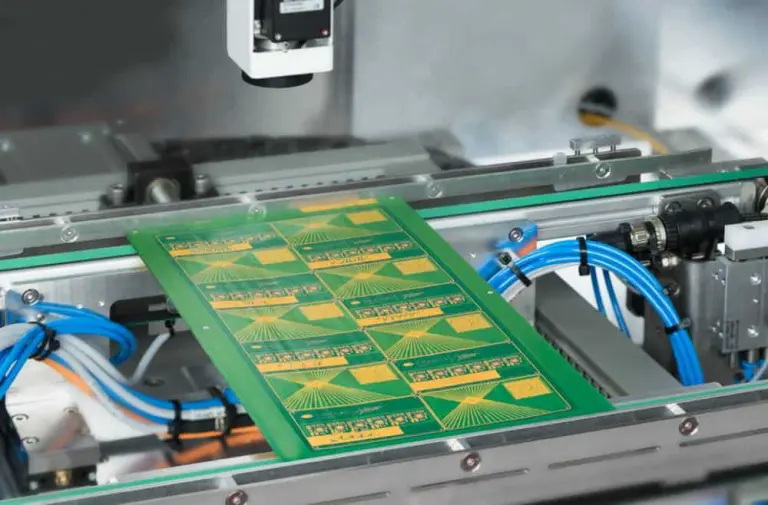

Surface Mount Technology (SMT) has become the backbone of modern electronics manufacturing, enabling the production of smaller, faster, and more reliable devices. Central to this process is the SMT stencil, a precision tool used to apply solder paste onto printed circuit boards (PCBs) accurately. However, the role of the SMT stencil envelope with a henger—a specialized packaging and handling system—has become equally critical in ensuring the quality, efficiency, and longevity of SMT stencils, thereby directly impacting the overall quality of electronics production.

This article explores why the SMT stencil envelope with a henger is essential, detailing its benefits, how it integrates into the SMT process, and why electronics manufacturers should prioritize its use for high-quality production outcomes.

What Is an SMT Stencil Envelope with a Henger?

Before delving into its importance, it is essential to understand what the SMT stencil envelope with a henger is:

- SMT Stencil Envelope: This is a protective packaging designed specifically for SMT stencils. It safeguards the stencil from contamination, damage, and environmental factors such as dust, moisture, and physical impact during storage and transport.

- Henger: A cylindrical or roller-like device used to hold, protect, and facilitate the handling of SMT stencils, especially framed stencils. The henger helps maintain the stencil's flatness and structural integrity, preventing warping or bending.

Together, the SMT stencil envelope with a henger forms a comprehensive solution that preserves the stencil's precision and usability throughout its lifecycle.

Why SMT Stencils Are Crucial in Electronics Production

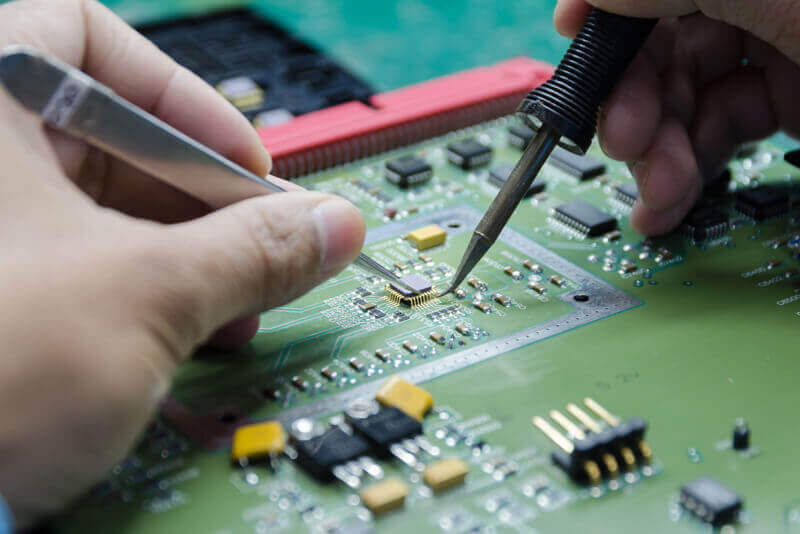

SMT stencils are thin sheets, typically made from stainless steel or nickel, with laser-cut or electroformed apertures that correspond exactly to the pads on a PCB. They enable precise solder paste deposition, which is critical for:

- Accurate component placement

- Reliable electrical connections

- Minimizing defects like bridging and tombstoning

- High production efficiency

The quality of the stencil directly influences the quality of the solder paste printing and, consequently, the final electronic assembly[1][5][11].

The Role of the SMT Stencil Envelope with a Henger in High-Quality Production

1. Protection from Contamination and Damage

SMT stencils require extreme cleanliness and precision. Any contamination such as dust, oils, or moisture can compromise solder paste deposition, leading to defects. The envelope acts as a sealed barrier, keeping the stencil clean during storage and transport.

The henger supports the stencil physically, preventing bending or warping that can occur if the stencil is mishandled or improperly stored. This physical protection ensures the stencil apertures remain perfectly aligned and undamaged, preserving print quality[5][7].

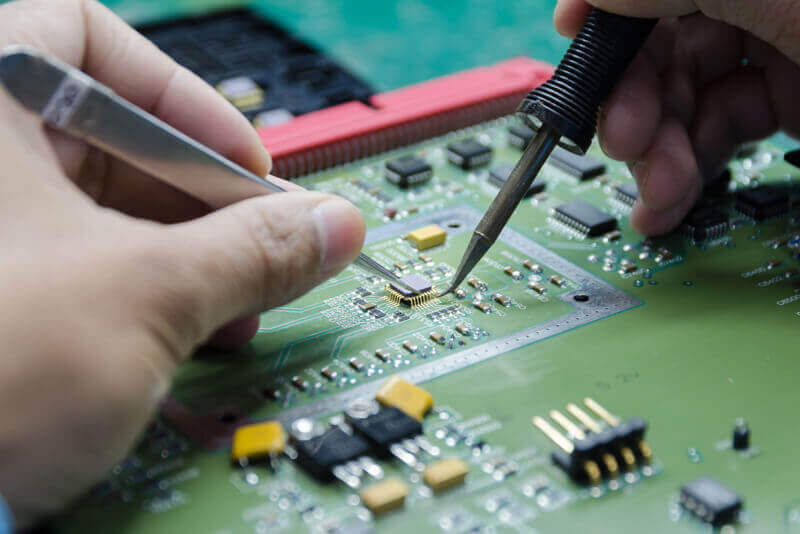

2. Maintaining Stencil Flatness and Structural Integrity

Warping or bending of SMT stencils can cause uneven solder paste deposition, resulting in poor solder joints and rework. The henger provides a stable cylindrical support that maintains the stencil's flatness, especially for framed stencils used in high-volume production.

By keeping the stencil flat and structurally sound, the henger helps ensure consistent printing performance over multiple production cycles[7][11].

3. Enhancing Handling and Storage Efficiency

SMT stencils are delicate and require careful handling. The envelope with a henger system simplifies storage and handling by:

- Providing a compact, organized way to store stencils without risk of damage

- Allowing easy identification and retrieval of stencils for different PCB designs

- Facilitating transportation between production lines or facilities without compromising stencil quality

This improves workflow efficiency and reduces downtime caused by stencil damage or misplacement[5][11].

4. Extending Stencil Lifespan and Reducing Costs

High-quality SMT stencils are an investment. Damage or contamination can necessitate frequent replacements, increasing production costs. The envelope with a henger protects this investment by:

- Minimizing wear and tear

- Preventing contamination that could degrade stencil apertures

- Reducing the frequency of stencil cleaning and maintenance

Longer stencil lifespan translates into lower operational costs and higher return on investment for manufacturers[5][7].

5. Supporting High-Volume and High-Precision Production

In high-volume electronics manufacturing, consistency and repeatability are paramount. The SMT stencil envelope with a henger ensures that each stencil used in production maintains its precision and cleanliness, which is critical for:

- Automated stencil printing systems that rely on exact stencil dimensions and aperture integrity

- Maintaining quality standards across multiple production batches

- Reducing defects and rework rates, thus improving overall product reliability[5][7][11]

How the SMT Stencil Envelope with a Henger Fits into the SMT Assembly Process

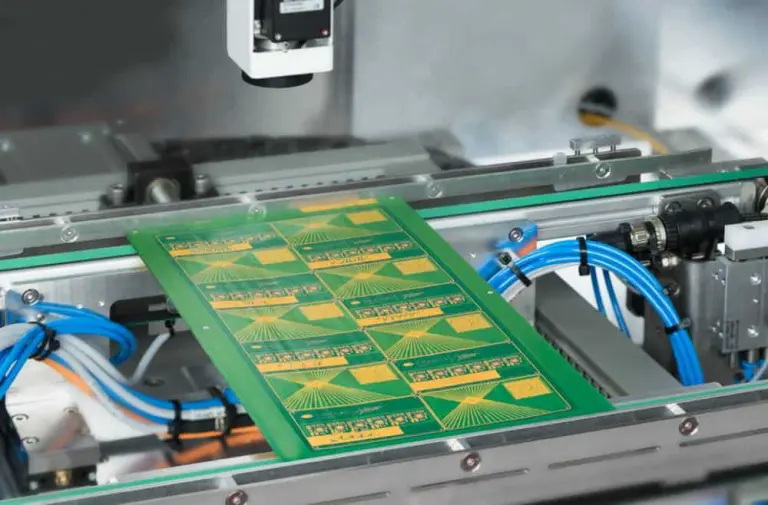

1. Stencil Fabrication: After manufacturing, the stencil is inspected and cleaned.

2. Packaging: The stencil is carefully placed in the SMT stencil envelope to protect it from contaminants.

3. Insertion into the Henger: The stencil, within its envelope, is mounted onto the henger for physical support.

4. Storage and Transport: The henger with the enclosed stencil is stored or transported to the production line.

5. Printing Process: The stencil is removed from the envelope and henger, then installed into the stencil printer for solder paste application.

6. Post-Use Handling: After use, the stencil is cleaned, inspected, and returned to its envelope and henger for storage.

This cycle ensures the stencil remains in optimal condition throughout its use, directly impacting the quality and efficiency of the SMT assembly process[5][11].

Benefits Summary of SMT Stencil Envelope with a Henger

| Benefit | Description |

| Contamination Protection | Prevents dust, oils, and moisture from compromising stencil apertures |

| Physical Damage Prevention | Protects against bending, warping, and scratches |

| Flatness Maintenance | Keeps stencil flat for consistent solder paste deposition |

| Handling Efficiency | Simplifies storage, retrieval, and transport |

| Cost Reduction | Extends stencil lifespan and reduces rework and replacement costs |

| Production Consistency | Ensures repeatable high-quality solder paste printing in high-volume manufacturing |

Conclusion

The SMT stencil envelope with a henger is an essential component in achieving high-quality electronics production. By protecting SMT stencils from contamination, physical damage, and deformation, it ensures precise solder paste deposition, which is critical for reliable PCB assembly. Additionally, this system enhances handling efficiency, extends stencil lifespan, and supports consistent, high-volume manufacturing. Electronics manufacturers aiming for superior product quality and cost-effective operations should integrate the SMT stencil envelope with a henger into their production workflow.

FAQ

1. What materials are typically used for SMT stencil envelopes and hengers?

SMT stencil envelopes are usually made from anti-static, dust-proof materials such as polyethylene or polypropylene films, while hengers are often constructed from durable plastics or lightweight metals designed to maintain stencil flatness and provide robust support[5][7].

2. Can the SMT stencil envelope with a henger be used for all types of SMT stencils?

Yes, the envelope with a henger system is adaptable for various SMT stencil types, including framed, frameless, laser-cut, and electroformed stencils, providing universal protection and handling benefits[7][11].

3. How does the use of a henger prevent stencil warping?

The henger supports the stencil along its length or circumference, distributing mechanical stress evenly and preventing bending or twisting that can cause warping, thus maintaining the stencil's flatness essential for accurate printing[7].

4. Does the envelope with henger system affect the cleaning process of SMT stencils?

No, the envelope with henger is used primarily for storage and transport. Stencils are removed from the envelope and henger before cleaning. Proper cleaning protocols remain unchanged and are critical for stencil maintenance[5].

5. How does the SMT stencil envelope with a henger contribute to reducing production defects?

By maintaining stencil cleanliness and structural integrity, the envelope with henger ensures consistent solder paste deposition, minimizing defects such as solder bridging, insufficient solder joints, and tombstoning, which improves overall product reliability[5][11].

Citations:

[1] https://www.twistedtraces.com/blog/understanding-smt-stencils-the-backbone-of-electronics-manufacturing

[2] https://levisonenterprises.com/5-advantages-to-using-smt/

[3] https://www.nextpcb.com/blog/smt-stencil

[4] https://tsie.in/blog/smt-assembly-process-in-electronics-manufacturing/

[5] https://pcb-copy.com/benefits-of-smt-stencil/

[6] https://www.stencils.co.uk/wp-content/uploads/2021/07/Tecan-stencils-handbook_WEB_compressed.pdf

[7] https://www.epectec.com/smt-stencils/

[8] https://www.multi-circuit-boards.eu/en/pcb-design-aid/smd-stencils.html

[9] https://www.ideaspcb.com/news/what-are-the-smt-stencil-design-specifications-53799316.html

[10] https://www.alibaba.com/showroom/stencil-smt.html

[11] https://jlcpcb.com/blog/guide-to-smt-stencils-in-pcb-assembly