Content Menu

● Understanding SMT and Its Impact on Electronics

>> Advantages of SMT

>> Challenges of SMT

● Why Professional SMT PCB Repair Is Essential

>> 1. Ensuring Device Longevity and Reliability

>> 2. Handling Complex and Miniaturized Components

>> 3. Preventing Costly Replacements and Downtime

>> 4. Maintaining Quality and Compliance

>> 5. Supporting Environmental Sustainability

● Common SMT PCB Repair Techniques

>> Visual and Automated Inspection

>> Reflow Soldering and Desoldering

>> Lifted Pad Repair

>> Component Replacement and Trace Repair

>> Manual Soldering and Rework

● The Risks of DIY SMT PCB Repair

● How to Choose a Professional SMT PCB Repair Service

● Future Trends in SMT PCB Repair

● Conclusion

● FAQ

>> 1. What is SMT PCB repair?

>> 2. Why is SMT PCB repair more challenging than traditional PCB repair?

>> 3. What tools are commonly used in professional SMT PCB repair?

>> 4. Can SMT PCB repair be done at home?

>> 5. How does SMT PCB repair contribute to environmental sustainability?

● Citations:

Surface Mount Technology (SMT) has revolutionized the electronics manufacturing industry by enabling the production of smaller, lighter, and more complex printed circuit boards (PCBs). However, with the miniaturization and complexity of SMT components, the need for professional SMT PCB repair has become critical to maintain the reliability and longevity of electronic devices. This article explores why professional SMT PCB repair is essential, the challenges involved, and the benefits it offers to electronics manufacturers and users.

Understanding SMT and Its Impact on Electronics

Surface Mount Technology (SMT) involves mounting electronic components directly onto the surface of a PCB, unlike traditional through-hole technology where component leads pass through holes in the board. SMT components, also known as Surface Mount Devices (SMDs), are typically smaller and allow for higher component density on PCBs, enabling more compact and efficient electronic designs.

Advantages of SMT

- Miniaturization: SMT allows for smaller components, leading to compact device designs.

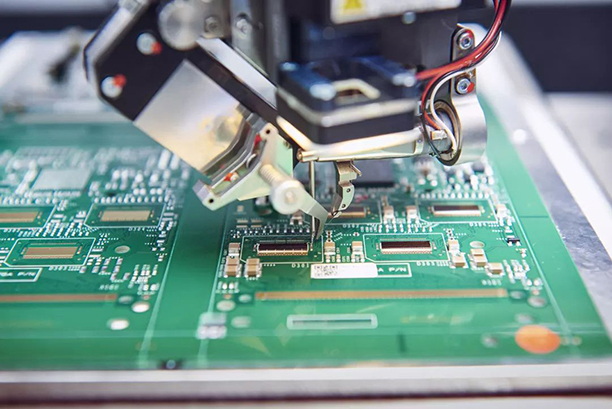

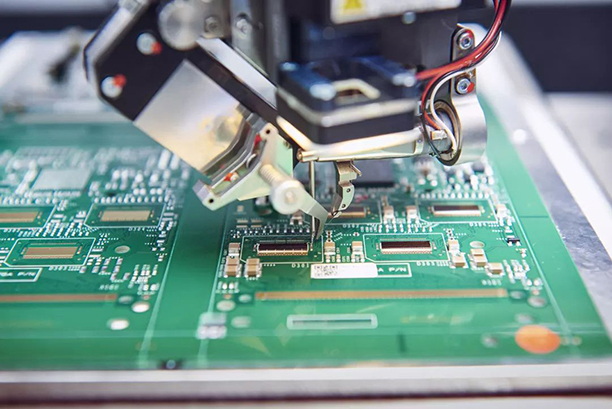

- Increased Automation: SMT processes are highly automated, improving production speed and consistency.

- Improved Reliability: SMT components often have better performance due to shorter lead lengths and reduced parasitic effects.

- Cost Efficiency: Reduced manual labor and material costs lower overall production expenses.

Challenges of SMT

- Fragility: SMT components are delicate and can be easily damaged during handling or operation.

- Complex Repair: The small size and dense placement of components require specialized skills and tools for repair.

- Inspection Difficulty: Visual inspection is challenging due to miniaturization and complex solder joints.

- High Technical Requirements: Repairing SMT PCBs demands advanced equipment and expertise.

Why Professional SMT PCB Repair Is Essential

1. Ensuring Device Longevity and Reliability

Electronic devices rely heavily on the integrity of their PCBs. Faulty or damaged SMT components can lead to device malfunction or failure. Professional SMT PCB repair ensures that defects such as lifted pads, solder bridges, misalignments, and broken traces are accurately diagnosed and repaired, restoring the device to optimal functionality. Without professional repair, these defects can cause intermittent failures or complete device breakdown, which can be costly and frustrating for both manufacturers and end-users.

2. Handling Complex and Miniaturized Components

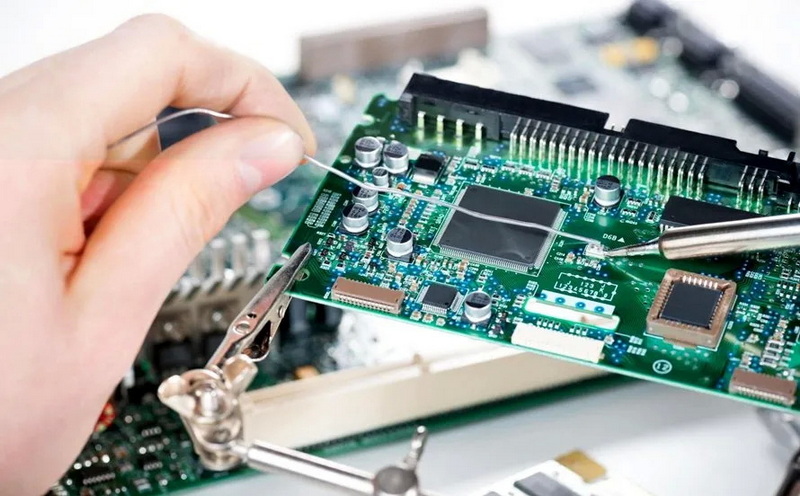

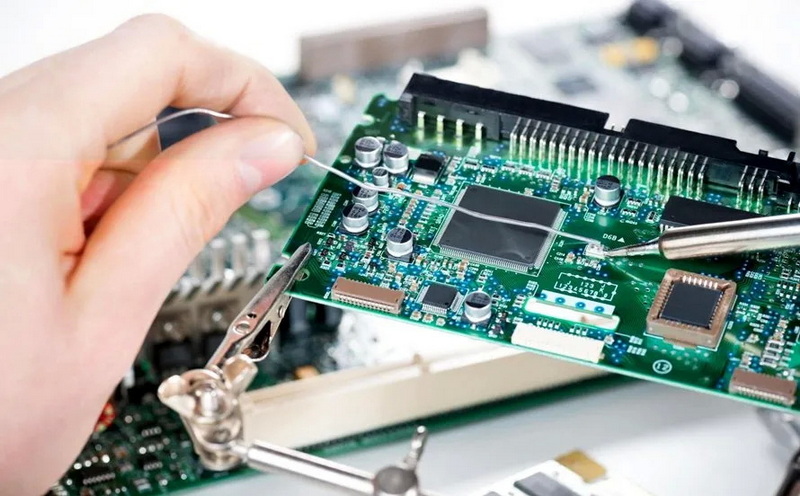

SMT components are often tiny and densely packed, making repair a delicate task. Professionals use specialized tools like temperature-controlled soldering irons, infrared rework stations, and microscopes to perform precise repairs without damaging adjacent components or the PCB substrate. The precision required to work on components that may be just a few millimeters in size demands years of experience and steady hands. Attempting to repair SMT PCBs without professional expertise often results in further damage, such as lifted pads or heat damage to the PCB layers.

3. Preventing Costly Replacements and Downtime

Replacing entire PCBs or electronic devices can be expensive and time-consuming. Professional SMT PCB repair can extend the life of existing electronics, saving costs on replacements and reducing downtime, which is especially critical in industrial, medical, and aerospace applications. For example, in a medical device, a malfunctioning PCB could halt critical patient monitoring equipment, risking lives and incurring substantial financial penalties. Professional repair minimizes these risks by providing fast, reliable fixes.

4. Maintaining Quality and Compliance

SMT inspection and repair are integral to quality control in electronics manufacturing. Professional repair services ensure that repaired PCBs meet industry standards and regulations, preventing failures that could lead to recalls or safety hazards. This is particularly important in sectors like automotive, aerospace, and healthcare, where product reliability is paramount and regulatory compliance is strictly enforced.

5. Supporting Environmental Sustainability

Repairing PCBs rather than discarding them contributes to environmental sustainability by reducing electronic waste. Professional SMT PCB repair promotes responsible electronics lifecycle management. The global electronic waste problem is growing rapidly, and extending the usable life of electronic components through repair helps mitigate this issue. Furthermore, repair processes often consume fewer resources than manufacturing new PCBs, reducing the environmental footprint.

Common SMT PCB Repair Techniques

Visual and Automated Inspection

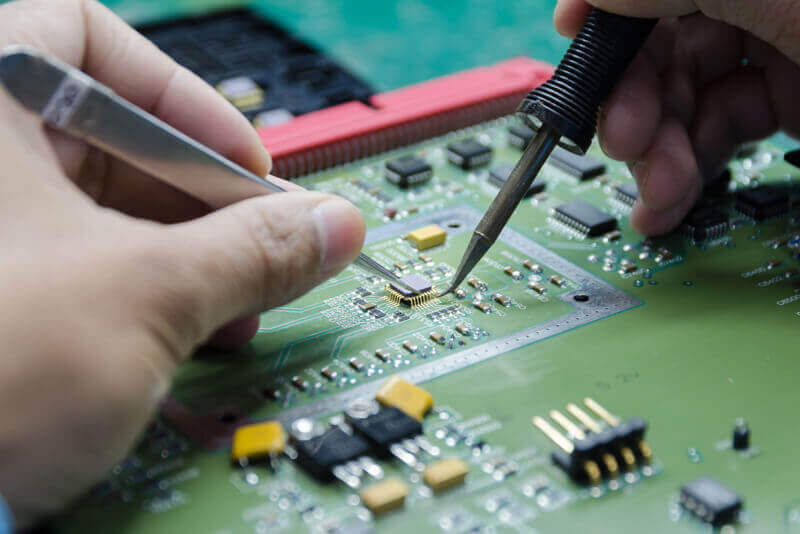

Before repair, thorough inspection is necessary to identify defects. Visual inspection, often aided by magnification tools, and automated methods like X-ray imaging and thermal cameras help detect soldering issues, misalignments, and component failures. Automated Optical Inspection (AOI) machines can scan PCBs quickly and accurately, highlighting potential problem areas that technicians can then examine in detail.

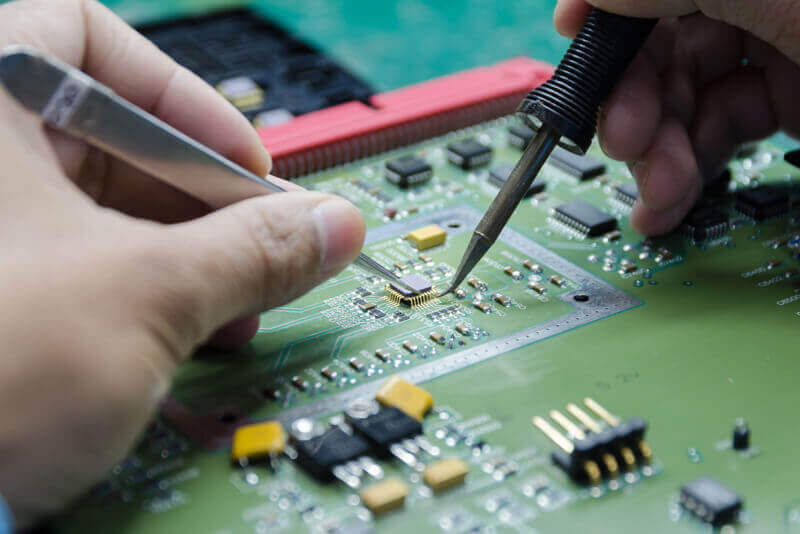

Reflow Soldering and Desoldering

Reflow soldering is used to attach or reattach SMT components by melting solder paste under controlled heat. Desoldering techniques, including hot air or infrared rework, remove defective components safely. These processes require precise temperature control to avoid damaging sensitive components or the PCB itself. Professional technicians calibrate their equipment carefully to match the specific requirements of each PCB and component type.

Lifted Pad Repair

Lifted pads occur when the copper pad detaches from the PCB substrate, a common SMT repair challenge. Repair involves cleaning the area, applying flux, carefully reattaching or replacing the pad, and ensuring solid solder joints without bridges or cold joints. This repair is delicate because the pad must be securely bonded to the board to maintain electrical connectivity and mechanical strength. Professionals often use conductive epoxy or specialized adhesives to restore lifted pads.

Component Replacement and Trace Repair

Damaged components are replaced with new ones, and broken PCB traces are repaired using jumper wires or conductive adhesives to restore electrical connectivity. Trace repair requires careful routing to avoid signal interference or impedance mismatch, especially in high-frequency circuits. Professionals use fine wire or copper tape to bridge damaged traces, ensuring the repaired path matches the original electrical characteristics as closely as possible.

Manual Soldering and Rework

Manual soldering requires skillful application of heat and solder to avoid damage. Techniques prioritize soldering smaller components first, ensuring proper alignment and avoiding excessive heat exposure. Professionals also use flux to improve solder flow and prevent oxidation, resulting in reliable joints that withstand mechanical and thermal stresses.

The Risks of DIY SMT PCB Repair

While it may be tempting to attempt SMT PCB repair at home or in-house without professional help, there are significant risks involved:

- Further Damage: Without proper tools and skills, you may damage other components or the PCB substrate.

- Poor Quality Repairs: Inadequate solder joints or misaligned components can cause intermittent failures.

- Safety Hazards: Improper handling of electronic components and soldering equipment can lead to electric shock or burns.

- Voiding Warranties: Unauthorized repairs may void manufacturer warranties, leading to higher costs in the long run.

For these reasons, entrusting SMT PCB repair to professionals is the safest and most effective choice.

How to Choose a Professional SMT PCB Repair Service

When selecting a professional SMT PCB repair provider, consider the following factors:

- Experience and Expertise: Look for technicians with proven experience in SMT repair across various industries.

- Advanced Equipment: Ensure the service uses modern tools such as infrared rework stations, microscopes, and AOI systems.

- Quality Certifications: Providers with ISO or IPC certifications demonstrate adherence to industry standards.

- Turnaround Time: Fast repair services minimize downtime and get your devices back in operation quickly.

- Customer Support: Responsive communication and post-repair support are important for long-term satisfaction.

Future Trends in SMT PCB Repair

As electronics continue to evolve, SMT PCB repair will adapt to new challenges and technologies:

- AI and Machine Learning: Automated defect detection and repair planning will become more sophisticated.

- Miniaturization: Even smaller components will require more precise repair tools and techniques.

- Advanced Materials: New PCB substrates and component materials may demand specialized repair methods.

- Remote Repair Assistance: Augmented reality (AR) and remote guidance could enable experts to assist technicians worldwide.

Staying informed about these trends will help manufacturers and repair professionals maintain high-quality SMT PCB repair services.

Conclusion

Professional SMT PCB repair is indispensable for maintaining the performance, reliability, and longevity of modern electronic devices. The complexity and miniaturization inherent in SMT require specialized skills, tools, and processes to effectively diagnose and repair defects. By investing in professional repair services, manufacturers and users can save costs, ensure quality, and contribute to sustainable electronics management. As SMT technology continues to evolve, the role of expert PCB repair will only grow in importance, supporting the advancement of electronics across all sectors.

FAQ

1. What is SMT PCB repair?

SMT PCB repair involves diagnosing and fixing defects on printed circuit boards that use Surface Mount Technology, including issues like soldering defects, lifted pads, and component failures.

2. Why is SMT PCB repair more challenging than traditional PCB repair?

Because SMT components are smaller, more densely packed, and more fragile than through-hole components, repairs require specialized tools and greater precision to avoid damaging the board or adjacent parts.

3. What tools are commonly used in professional SMT PCB repair?

Tools include temperature-controlled soldering irons, infrared rework stations, microscopes, flux applicators, desoldering braid, and sometimes X-ray imaging systems for multilayer boards.

4. Can SMT PCB repair be done at home?

Due to the complexity and precision required, professional SMT PCB repair is recommended. Home repairs without proper tools and expertise risk further damage to the PCB and components.

5. How does SMT PCB repair contribute to environmental sustainability?

By repairing rather than discarding PCBs, electronic waste is reduced, promoting a more sustainable lifecycle for electronic devices.

Citations:

1.https://www.linkedin.com/pulse/importance-types-smt-inspection-electronics-manufacturing-rzfac

2.https://emsginc.com/resources/5-most-common-pcb-repairs/

3.https://blog.matric.com/what-is-smt-assembly

4.https://www.reddit.com/r/AskElectronics/comments/15ir0w6/how_profitable_is_component_level_circuit_board/

5.https://www.ipcb.com/pcb-blog/10236.html

6.https://www.anzer-usa.com/resources/smt-lifted-pad-repair/

7.https://www.youtube.com/watch?v=oFCab83pAug

8.https://www.wevolver.com/article/smt-process

9.https://www.hoyogo.com/news/Six-Rework-and-Repair-Skills-for-Bad-SMT.html

10.https://en.wikipedia.org/wiki/Surface_mount

11.https://baike.baidu.com/item/%E7%94%B5%E5%AD%90%E7%BB%84%E8%A3%85%E6%8A%80%E6%9C%AF%E4%B8%93%E4%B8%9A%E8%8B%B1%E8%AF%AD/12086345