Content Menu

● Introduction

● The Role of Precision in SMT Nozzle Manufacturing

>> Importance of Accurate Placement

>> Enhancing Product Reliability

● Benefits of Precision in Electronics Assembly

>> Enhanced Product Quality

>> Increased Efficiency

>> Cost Savings

>> Support for Miniaturization

● Challenges and Solutions in Achieving Precision

>> Common Challenges

>> Solutions for Maintaining Precision

● Technological Advancements in SMT Nozzle Precision

>> AI-Driven Calibration Systems

>> Smart Nozzles with Real-Time Feedback

>> Robotics Integration

● The Impact of Nozzle Calibration on Precision

>> Importance of Calibration

>> Calibration Techniques

● The Integral Role of Nozzles in Modern Electronics Assembly

>> Factors Influencing Nozzle Performance

>> Advanced Technologies Enhancing Nozzle Functionality

● Conclusion

● FAQ

>> 1. Why is precision critical in SMT nozzle manufacturing?

>> 2. How does precision affect the quality of electronics assembly?

>> 3. What are the common challenges in maintaining precision?

>> 4. What technologies are used to enhance precision?

>> 5. How does precision contribute to cost efficiency?

● Citations:

Introduction

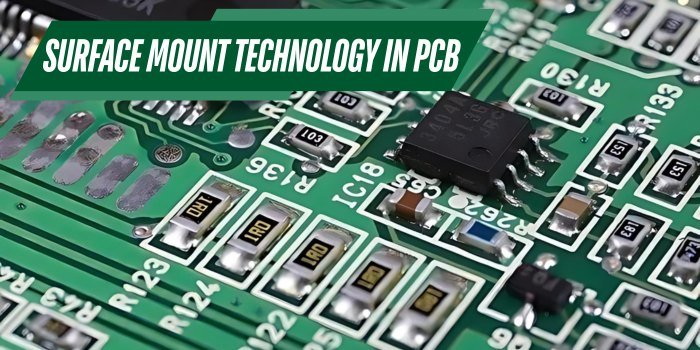

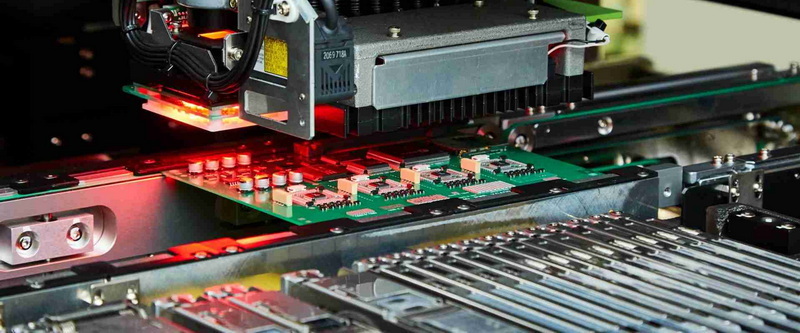

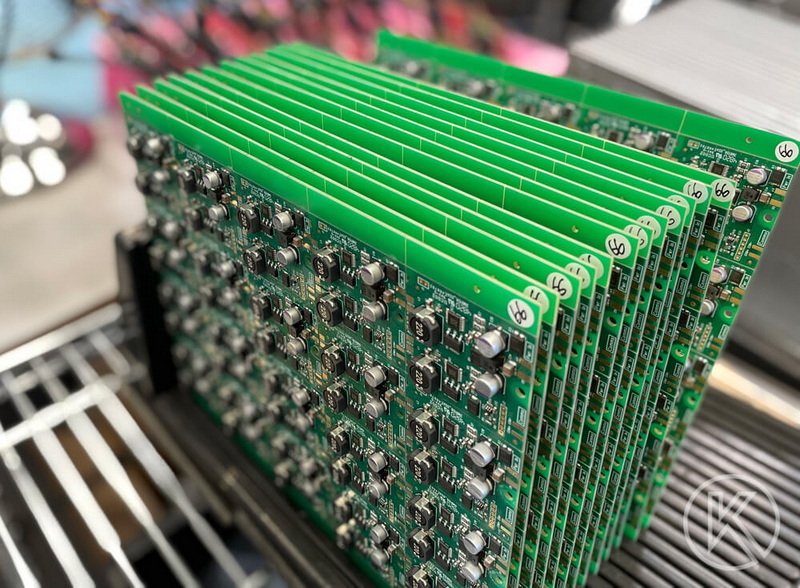

Surface Mount Technology (SMT) nozzle manufacturing plays a pivotal role in the electronics assembly process. As electronic devices become increasingly compact and complex, the demand for precision in SMT nozzle production has never been greater. This article explores the critical importance of precision in SMT nozzle manufacturing and its far-reaching impact on the electronics industry.

The Role of Precision in SMT Nozzle Manufacturing

Precision in SMT nozzle manufacturing ensures accurate placement of components on printed circuit boards (PCBs). Misalignment or inaccuracies can lead to defects, reduced product reliability, and increased production costs. High-precision nozzles are designed to handle delicate components with care, ensuring optimal functionality and durability.

Importance of Accurate Placement

The primary function of SMT nozzles is to pick and place components onto PCBs. Each nozzle must be calibrated to ensure it aligns perfectly with the designated placement points on the board. Any deviation can result in:

- Misplaced Components: Incorrectly placed components can lead to functional failures, affecting the overall performance of electronic devices.

- Increased Defect Rates: Misalignment increases the likelihood of defects, necessitating rework or scrapping of products.

- Higher Production Costs: Errors in placement can lead to increased labor costs and material waste, impacting profitability.

Enhancing Product Reliability

Precision not only affects the initial assembly but also influences long-term reliability. Components that are not placed correctly may experience mechanical stress or improper solder connections, leading to premature failure. High-precision nozzles help mitigate these risks by ensuring that components are placed accurately every time.

Benefits of Precision in Electronics Assembly

The advantages of precision in SMT nozzle manufacturing extend beyond mere accuracy. They encompass several critical aspects that enhance overall production efficiency and product quality.

Enhanced Product Quality

- Reduced Risk of Misplacement: Precise nozzles minimize the risk of misalignment, ensuring that components are correctly positioned for soldering.

- Improved Electrical Performance: Accurate placement leads to better electrical connections, reducing failure rates and enhancing product reliability.

Increased Efficiency

- Faster Production Speeds: Automation enabled by precision nozzles accelerates production while maintaining consistency. This is particularly important in high-volume manufacturing environments where time-to-market is critical.

- Higher Throughput: With precise nozzles, manufacturers can achieve higher placement rates, increasing overall productivity without sacrificing quality.

Cost Savings

- Lower Defect Rates: Reduced misplacements translate to fewer defects and less rework, leading to significant cost savings over time.

- Higher Profit Margins: By minimizing waste and maximizing efficiency, manufacturers can improve their profit margins significantly.

Support for Miniaturization

As electronic devices continue to shrink in size, the need for precision becomes even more critical. High-density PCBs require precise component placement to accommodate smaller parts without compromising functionality. Precision nozzles enable manufacturers to assemble these compact designs effectively.

Challenges and Solutions in Achieving Precision

Maintaining precision in SMT nozzle manufacturing is not without challenges. Several factors can impact accuracy, including material inconsistencies, wear and tear, and calibration issues.

Common Challenges

1. Material Inconsistencies: Variations in material quality can affect the performance of nozzles over time.

2. Wear and Tear: Frequent use can lead to degradation of nozzle performance, impacting placement accuracy.

3. Calibration Issues: Inadequate calibration processes can result in misalignment during component placement.

Solutions for Maintaining Precision

To address these challenges, manufacturers can implement several strategies:

- Regular Maintenance: Routine checks and maintenance can help identify wear before it impacts performance.

- Advanced Calibration Techniques: Employing sophisticated calibration methods ensures that nozzles remain aligned with PCB specifications.

- High-Quality Materials: Using durable materials designed for longevity can reduce wear-related issues.

Technological Advancements in SMT Nozzle Precision

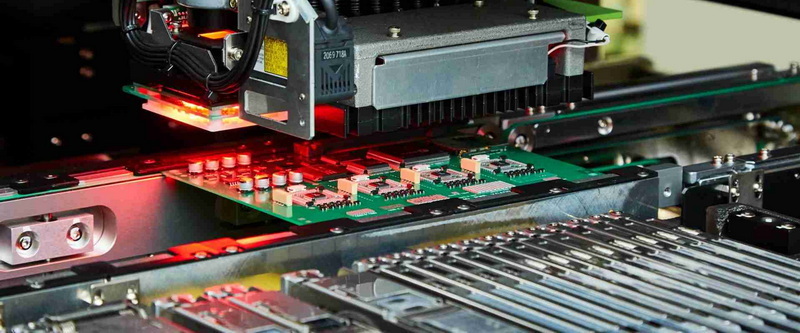

Recent advancements in technology have significantly improved the precision of SMT nozzles. Innovations such as AI-driven calibration systems, smart nozzles with real-time feedback, and the integration of robotics have revolutionized the manufacturing process.

AI-Driven Calibration Systems

These systems utilize artificial intelligence to automate the calibration process, ensuring that each nozzle is adjusted accurately based on real-time data from the assembly line. This reduces human error and enhances overall precision.

Smart Nozzles with Real-Time Feedback

Smart nozzles equipped with sensors provide immediate feedback on their performance during operation. This allows for instant adjustments and corrections, further improving placement accuracy.

Robotics Integration

The use of robotics in SMT assembly has streamlined operations, enabling faster and more precise movements during component placement. Robots equipped with high-precision nozzles can operate at speeds unattainable by manual processes while maintaining consistent quality.

The Impact of Nozzle Calibration on Precision

Calibration is a critical process that directly affects the precision of SMT nozzles. Proper calibration ensures that nozzles are aligned correctly with component locations on PCBs. The calibration process involves specialized software routines that measure and adjust nozzle positions before assembly begins.

Importance of Calibration

- Alignment Accuracy: Calibration ensures that each nozzle is aligned precisely with its corresponding component location on the PCB.

- Consistency Over Time: Regular calibration helps maintain consistent performance across multiple production runs, reducing variability in component placement.

- Error Prevention: By identifying potential misalignments before they occur, calibration minimizes errors during assembly processes.

Calibration Techniques

Various techniques are employed to achieve optimal calibration:

- Visual Inspection Systems: High-resolution cameras capture images during assembly to verify component alignment.

- Automated Measurement Tools: These tools assess nozzle positions against predefined standards to ensure accuracy.

- Routine Checks: Scheduled calibration routines help maintain alignment integrity over time.

The Integral Role of Nozzles in Modern Electronics Assembly

SMT (Surface Mount Technology) nozzles are essential components that significantly impact the efficiency and accuracy of the assembly process. They are responsible for gripping various surface mount components and ensuring accurate placement on printed circuit boards (PCBs).

Factors Influencing Nozzle Performance

1. Design Specifications: The design of a nozzle must match specific component types and sizes for optimal performance.

2. Material Selection: The choice of materials affects durability and performance under varying operational conditions.

3. Maintenance Practices: Regular cleaning and maintenance prevent debris accumulation that could hinder nozzle function.

Advanced Technologies Enhancing Nozzle Functionality

Incorporating advanced technologies such as sensors for feedback on component presence can further refine the performance of these nozzles:

- Dynamic Adjustments: Sensors allow real-time adjustments based on component weight or environmental conditions.

- Predictive Maintenance: Monitoring systems analyze wear patterns to predict maintenance needs before failures occur.

- Interchangeable Tips: Modular designs enable quick changes between different nozzle tips for handling various components efficiently.

Conclusion

Precision in SMT nozzle manufacturing is a cornerstone of successful electronics assembly. It ensures product quality, supports innovation, and drives cost efficiency. As the electronics industry continues to evolve, the emphasis on precision will remain a critical factor in meeting modern technology demands. The ongoing advancements in technology promise even greater levels of accuracy and efficiency in future manufacturing processes.

FAQ

1. Why is precision critical in SMT nozzle manufacturing?

Precision is essential to ensure accurate placement of components, reducing defects and enhancing product reliability.

2. How does precision affect the quality of electronics assembly?

High precision minimizes errors in component placement, leading to better electrical performance and reduced failure rates.

3. What are the common challenges in maintaining precision?

Challenges include material inconsistencies, wear and tear, and calibration issues which can be mitigated through regular maintenance and advanced technologies.

4. What technologies are used to enhance precision?

Technologies such as AI-driven calibration systems, smart nozzles with real-time feedback, and robotics are used to improve accuracy and efficiency.

5. How does precision contribute to cost efficiency?

Precision reduces defects and rework, leading to lower production costs and higher profitability.

Citations:

[1] https://www.zjyingxing.com/info/what-is-the-role-of-nozzle-calibration-in-smt-87605940.html

[2] https://www.rhsmt.com/news/the-integral-role-of-smt-nozzles-in-modern-electronics-assembly/

[3] https://www.proplate.com/what-role-do-precision-machined-parts-play-in-ensuring-the-accuracy-and-functionality-of-electronic-devices/

[4] https://iconnect007.com/index.php/article/52613/smt-preventive-maintenance-stop-5-major-problems-with-pick-and-place-nozzles/52616

[5] http://www.smtcpu.com

[6] https://shieldworksmfg.com/the-importance-of-accuracy-a-closer-look-at-precision-assembly/

[7] https://www.qosmt.com/a/blog/technical/2024/0123/1226.html

[8] https://www.adspcba.com/optimizing-smt-pick-and-place-nozzle-performance-for-efficiency/

[9] https://www.pcbnet.com/precision-pcb-assembly/

[10] https://www.zjyingxing.com/info/significance-of-smt-mounter-precision-48470070.html