Content Menu

● The Fundamentals of SMT and Reflow Soldering

>> The SMT Reflow Process

● The Importance of Temperature Control in Reflow Ovens

>> The Four Zones of a Reflow Oven

● Advantages of Using SMT Reflow Ovens

>> Increased Production Efficiency

>> Improved Soldering Quality

>> Ability to Handle Complex Designs

>> Reduced Labor Costs

>> Compatibility with Lead-Free Soldering

● Challenges and Considerations in Reflow Soldering

>> Temperature Sensitivity of Components

>> Thermal Profiling

>> Solder Paste Selection

>> Maintenance and Calibration

● Innovations in SMT Reflow Oven Technology

>> Nitrogen Atmosphere Reflow

>> Multi-Zone Ovens

>> Integrated Cooling Systems

>> Smart Controls and Data Logging

● The Future of SMT Reflow Technology

>> Integration with Industry 4.0

>> Enhanced Energy Efficiency

>> Artificial Intelligence and Machine Learning

● Conclusion

● FAQ

>> 1. What is the difference between lead and lead-free soldering in SMT reflow ovens?

>> 2. How does the size of a PCB affect the reflow soldering process?

>> 3. What are the common defects in reflow soldering, and how can they be prevented?

>> 4. How do you determine the right reflow profile for a specific PCB assembly?

>> 5. What are the environmental considerations when using SMT reflow ovens?

● Citations:

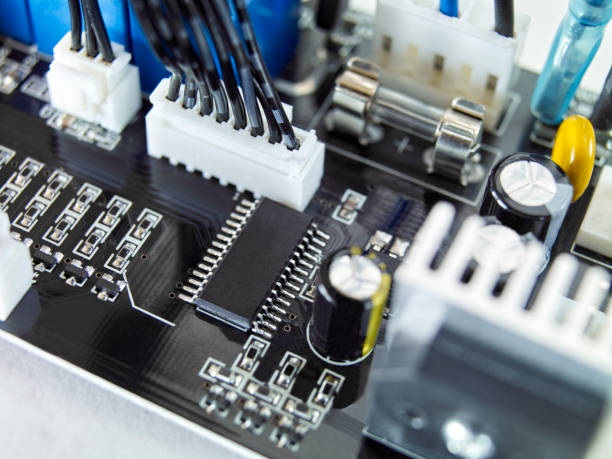

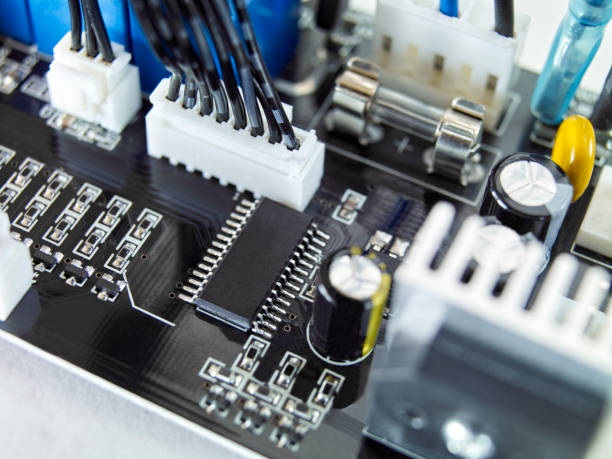

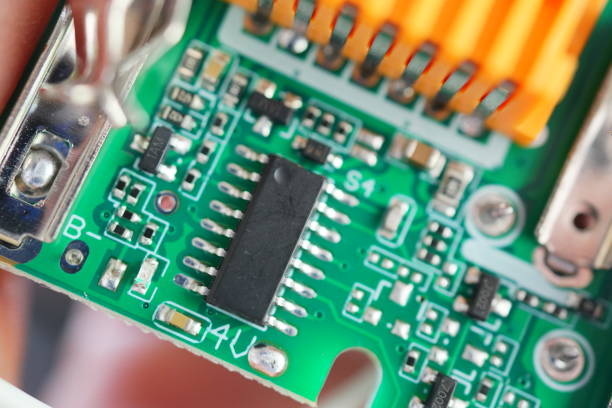

In the ever-evolving world of electronics manufacturing, Surface Mount Technology (SMT) has become the cornerstone of modern Printed Circuit Board (PCB) assembly. At the heart of this revolutionary process lies a crucial piece of equipment: the SMT Reflow Oven. This sophisticated machine plays a pivotal role in ensuring that electronic components are securely and accurately soldered onto PCBs, making it an indispensable tool in the production of high-quality electronic devices[5].

The Fundamentals of SMT and Reflow Soldering

Surface Mount Technology represents a significant advancement in electronic circuit manufacturing. Unlike traditional through-hole soldering techniques, SMT allows for the direct mounting of electronic components onto the surface of PCBs. This approach has enabled the production of smaller, more complex, and more reliable electronic devices, becoming the industry standard in electronics manufacturing[5].

The SMT Reflow Process

The SMT reflow process is a meticulously controlled sequence of steps designed to create robust and reliable solder joints. Let's delve into each stage of this critical process:

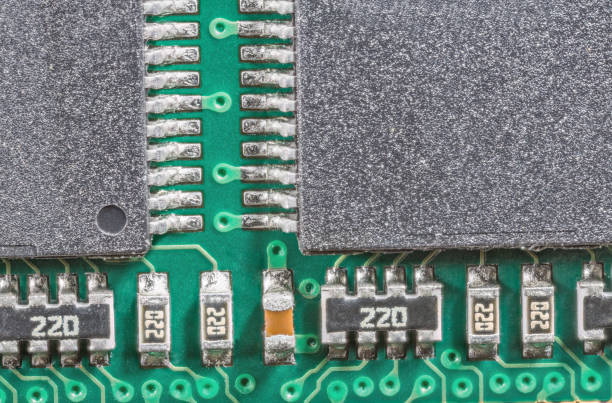

1. Application of Solder Paste: The journey begins with the precise application of solder paste to the contact pads on the PCB. This is typically done using a stencil, ensuring that the right amount of paste is deposited exactly where it's needed[5].

2. Component Placement: Once the solder paste is applied, surface-mounted components are accurately positioned on the PCB. This step is usually performed by automated pick-and-place machines, which can place components with incredible precision[2].

3. Preheating: As the PCB enters the reflow oven, it first undergoes a preheating phase. This gradual increase in temperature serves to remove any moisture or solvents from the solder paste and prepares the assembly for the soldering process[2].

4. Thermal Soak: Following the preheat stage, the PCB enters the thermal soak zone. Here, the temperature is held steady for 1 to 2 minutes, ensuring that all components reach a uniform temperature. This phase is crucial for preparing the assembly for the subsequent melting process[5].

5. Reflow Soldering: In this critical phase, the temperature is raised above the melting point of the solder paste. This causes the solder to liquefy and form secure connections between the component leads/pads and the PCB. The time during which the solder remains above its melting point (known as time above liquidus) is carefully controlled, typically lasting between 30 to 60 seconds[3].

6. Cooling: After the reflow phase, the PCB assembly is gradually cooled. This controlled cooling process allows the solder to solidify, forming strong and reliable electrical connections[2].

The Importance of Temperature Control in Reflow Ovens

One of the most critical aspects of the reflow process is precise temperature control. SMT reflow ovens are designed to provide exacting control over temperature profiles, ensuring consistent and reliable soldering results[2].

The Four Zones of a Reflow Oven

A typical SMT reflow oven is divided into four distinct zones, each playing a crucial role in the soldering process:

1. Preheat Zone: This initial zone gradually raises the temperature of the PCB assembly, preventing thermal shock to the components. The preheat rate is typically between 1 and 3°C per second[9].

2. Soak Zone: Set between 120°C and 160°C, this zone further heats the PCB, ensuring complete evaporation of moisture from solder pads and component pins. It's crucial for achieving a uniform temperature across the board before entering the reflow zone[6].

3. Reflow Zone: This is the most critical stage of the process. The temperature quickly rises to around 245°C (though this can vary depending on the solder paste used), causing the solder to melt and form connections between components and PCB pads[6].

4. Cooling Zone: After reflow, the PCB is cooled at a controlled rate, typically 2 to 4°C per second. This gradual cooling ensures strong solder joints and minimizes thermal stress on the components[5].

Advantages of Using SMT Reflow Ovens

The adoption of SMT reflow ovens in PCB assembly offers numerous benefits:

Increased Production Efficiency

SMT reflow ovens significantly boost production efficiency. They can process multiple PCBs simultaneously, dramatically increasing throughput compared to manual soldering methods. This efficiency is particularly crucial in high-volume manufacturing environments[5].

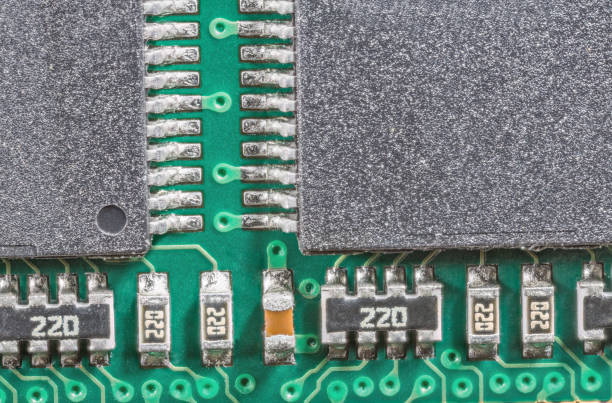

Improved Soldering Quality

The precise temperature control offered by reflow ovens results in consistently high-quality solder joints. This precision minimizes defects such as cold solder joints or solder bridges, which are more common with manual soldering techniques[2].

Ability to Handle Complex Designs

As electronic devices become increasingly compact and sophisticated, PCB designs have grown more complex. SMT reflow ovens can handle these intricate designs, soldering components with fine pitches and small form factors that would be challenging or impossible to solder manually[5].

Reduced Labor Costs

By automating the soldering process, SMT reflow ovens significantly reduce the need for skilled manual labor. This not only cuts costs but also improves consistency in the manufacturing process[2].

Compatibility with Lead-Free Soldering

With environmental regulations pushing for lead-free electronics, SMT reflow ovens have proven invaluable. They can achieve the higher temperatures required for lead-free solders while maintaining precise control over the reflow profile[3].

Challenges and Considerations in Reflow Soldering

While SMT reflow ovens offer numerous advantages, they also present some challenges that manufacturers must address:

Temperature Sensitivity of Components

Different electronic components have varying levels of heat sensitivity. Some may be damaged if exposed to excessive temperatures during the reflow process. This necessitates careful planning of the reflow profile to ensure all components are properly soldered without being damaged[3].

Thermal Profiling

Creating the optimal thermal profile for a specific PCB assembly can be complex. Factors such as board thickness, component density, and thermal mass all influence the ideal temperature curve. Manufacturers often need to invest time in developing and fine-tuning profiles for each new product[5].

Solder Paste Selection

The choice of solder paste is crucial in reflow soldering. Different pastes have different melting points and flow characteristics. Selecting the right paste for the specific application and ensuring it's compatible with the chosen reflow profile is essential for achieving high-quality results[3].

Maintenance and Calibration

To maintain consistent performance, SMT reflow ovens require regular maintenance and calibration. This includes cleaning to prevent contamination from flux residues and ensuring temperature sensors remain accurate over time[2].

Innovations in SMT Reflow Oven Technology

The field of SMT reflow technology continues to evolve, with several exciting innovations enhancing the capabilities of these crucial machines:

Nitrogen Atmosphere Reflow

Some advanced reflow ovens now incorporate nitrogen atmospheres. By displacing oxygen during the reflow process, these systems can improve wetting and reduce oxidation, resulting in higher quality solder joints, especially for lead-free solders[5].

Multi-Zone Ovens

Modern reflow ovens often feature an increased number of heating zones, sometimes up to 12 or more. This allows for even finer control over the temperature profile, enabling manufacturers to create more precise and complex reflow curves[5].

Integrated Cooling Systems

Advanced cooling systems, including forced air and water-cooled options, are being integrated into reflow ovens. These systems allow for more rapid and controlled cooling, which can improve solder joint quality and reduce thermal stress on components[2].

Smart Controls and Data Logging

The latest reflow ovens incorporate advanced control systems and data logging capabilities. These features allow for real-time monitoring of the reflow process, easy profile adjustment, and comprehensive tracking of production data for quality control purposes[5].

The Future of SMT Reflow Technology

As the electronics industry continues to push the boundaries of miniaturization and complexity, SMT reflow technology is expected to evolve further:

Integration with Industry 4.0

Future reflow ovens are likely to become more integrated with broader manufacturing systems, aligning with Industry 4.0 principles. This could include real-time data sharing, predictive maintenance capabilities, and seamless integration with other production line equipment[5].

Enhanced Energy Efficiency

With a growing focus on sustainability, future reflow ovens may incorporate more energy-efficient designs. This could include better insulation, heat recovery systems, and more efficient heating elements[2].

Artificial Intelligence and Machine Learning

The integration of AI and machine learning algorithms could revolutionize reflow profiling. These technologies could potentially analyze vast amounts of production data to automatically optimize reflow profiles for different PCB designs, further improving quality and efficiency[5].

Conclusion

SMT reflow ovens have become an indispensable tool in modern PCB assembly, revolutionizing the electronics manufacturing industry. Their ability to provide precise temperature control, handle complex designs, and improve overall production efficiency has made them essential in creating the sophisticated electronic devices we rely on daily.

As technology continues to advance, SMT reflow ovens will undoubtedly evolve, incorporating new features and capabilities to meet the ever-increasing demands of the electronics industry. From improved energy efficiency to integration with AI and Industry 4.0 principles, the future of SMT reflow technology looks bright.

For manufacturers in the electronics industry, investing in high-quality SMT reflow ovens and staying abreast of technological advancements in this field is crucial. By doing so, they can ensure they remain competitive in an industry where precision, efficiency, and quality are paramount.

FAQ

1. What is the difference between lead and lead-free soldering in SMT reflow ovens?

Lead-based solder typically has a melting point around 183°C, while lead-free solder melts at higher temperatures, usually between 217-220°C. This difference necessitates adjustments in the reflow profile, with lead-free soldering requiring higher peak temperatures. SMT reflow ovens must be capable of reaching and maintaining these higher temperatures while still providing precise control to avoid damaging heat-sensitive components[1].

2. How does the size of a PCB affect the reflow soldering process?

The size of a PCB can significantly impact the reflow soldering process. Larger PCBs have more thermal mass, which can lead to uneven heating across the board. This may require adjustments to the reflow profile, such as longer soak times or higher temperatures, to ensure all areas of the board reach the necessary temperature for proper soldering. Some reflow ovens are designed with multiple heating zones to address this issue, allowing for more precise temperature control across larger boards[5].

3. What are the common defects in reflow soldering, and how can they be prevented?

Common defects in reflow soldering include solder bridges (where excess solder connects adjacent pads), tombstoning (where a component stands on end), and cold solder joints (where the solder doesn't properly wet the pad or component lead). These defects can often be prevented through proper solder paste application, accurate component placement, and optimized reflow profiles. Regular maintenance of the reflow oven, including cleaning and calibration, also helps prevent defects by ensuring consistent performance[3].

4. How do you determine the right reflow profile for a specific PCB assembly?

Determining the right reflow profile involves considering several factors, including the type of solder paste used, the thermal characteristics of the PCB and components, and the density of components on the board. Typically, manufacturers start with a recommended profile from the solder paste manufacturer and then adjust it based on thermal profiling of the specific PCB assembly. This may involve attaching thermocouples to various points on the board and running it through the oven to measure actual temperatures. The profile is then fine-tuned to ensure all areas of the board reach the necessary temperatures without exceeding the thermal limits of any components[5].

5. What are the environmental considerations when using SMT reflow ovens?

Environmental considerations for SMT reflow ovens include energy consumption, as these ovens can be significant energy users in a manufacturing facility. Many modern ovens are designed with improved insulation and more efficient heating elements to reduce energy use. Another consideration is the use of lead-free solder, which is becoming increasingly common due to environmental regulations. This shift has required adjustments in reflow oven technology to handle the higher temperatures needed for lead-free soldering. Additionally, proper ventilation is crucial to manage fumes produced during the soldering process, which can contain potentially harmful substances[1][3].

Citations:

[1] https://electrotrail.com/2018/10/12/importance-of-the-reflow-oven-in-smt-process/

[2] https://www.anzer-usa.com/resources/reflow-oven/

[3] https://www.pcbonline.com/blog/tips-for-reflow-soldering.html

[4] https://www.instructables.com/DIY-SMT-Hotplate-Project/

[5] https://hilelectronic.com/reflow-oven/

[6] https://jlcpcb.com/help/article/reflow-soldering-principles-and-precautions

[7] http://www.1clicksmt-reflowoven.com/faq.html

[8] https://www.instructables.com/Hack-a-Toaster-Oven-for-Reflow-Soldering/

[9] https://www.wevolver.com/article/reflow-soldering