Content Menu

● Understanding SMT Spacers and Their Role in PCB Assembly

● Advantages of Unthreaded SMT Spacers for PCB

>> 1. Simplified Assembly and Handling

>> 2. Enhanced Process Reliability

>> 3. Cost Efficiency

>> 4. Flexibility in Design and Material Choice

>> 5. Reduced Risk of PCB Damage

● Common Applications of Unthreaded SMT Spacers

● Material Comparison for Unthreaded SMT Spacers

● Design Considerations When Using Unthreaded SMT Spacers

● Comparison Between Threaded and Unthreaded SMT Spacers

● Conclusion

● FAQ

>> 1. What are unthreaded SMT spacers used for in PCB assembly?

>> 2. How do unthreaded SMT spacers improve assembly efficiency?

>> 3. What materials are commonly used for unthreaded SMT spacers?

>> 4. Are unthreaded SMT spacers suitable for high-temperature environments?

>> 5. Can unthreaded SMT spacers be used in load-bearing applications?

In the world of printed circuit board (PCB) assembly, choosing the right spacers is crucial for ensuring mechanical stability, electrical insulation, and overall system reliability. Among the various types of spacers, surface-mount technology (SMT) spacers play a vital role in elevating and supporting PCBs during assembly and operation. This article explores why unthreaded SMT spacers are often preferred over threaded options for PCB applications, highlighting their advantages, material options, and practical considerations.

Understanding SMT Spacers and Their Role in PCB Assembly

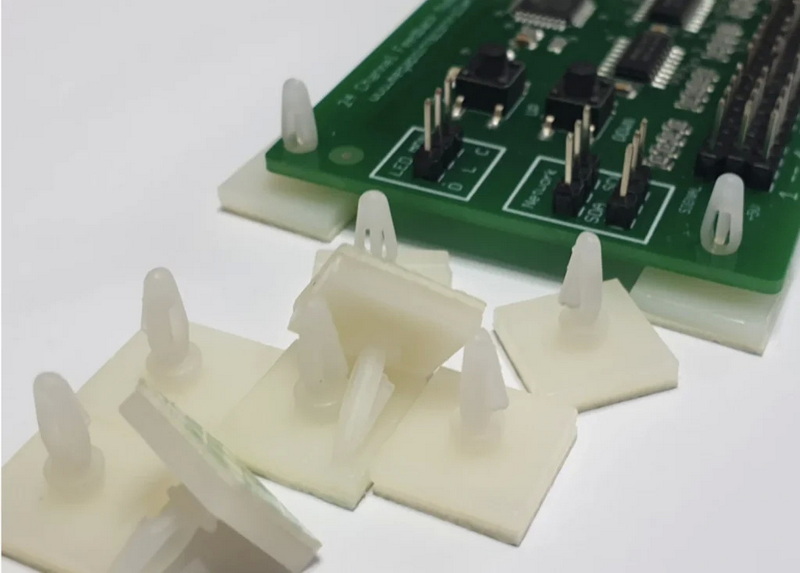

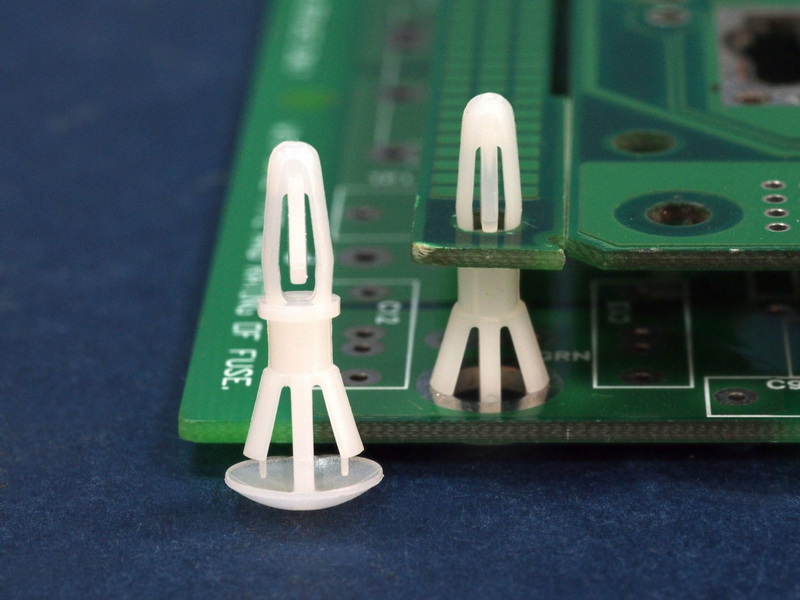

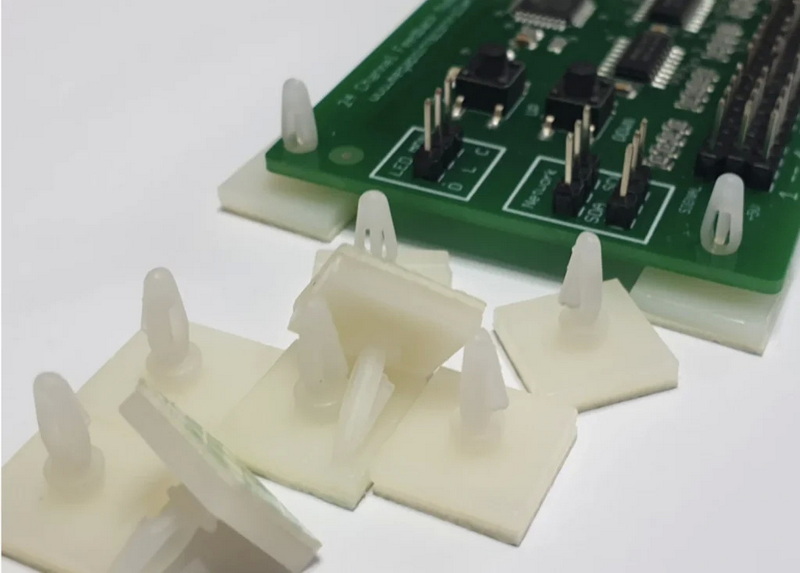

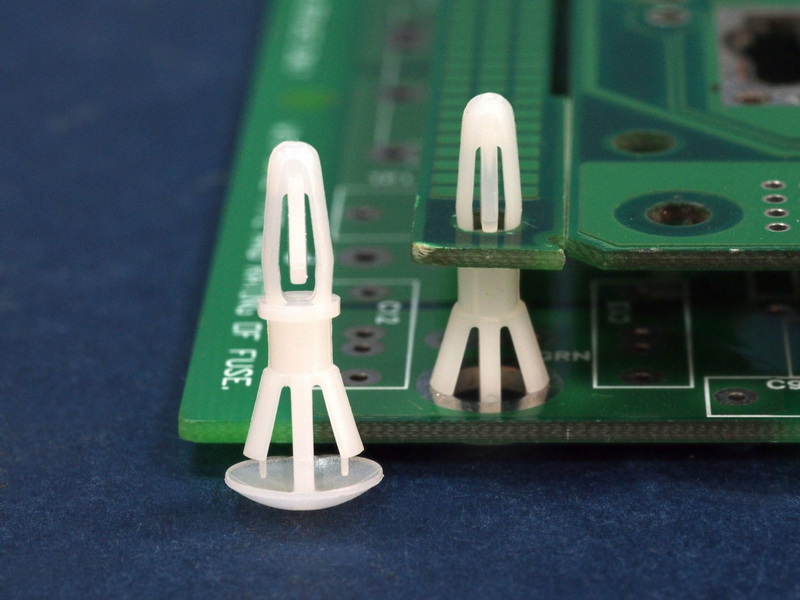

SMT spacers are small components designed to create precise spacing between the PCB and other elements such as chassis, other boards, or components. They help prevent short circuits, reduce mechanical stress, and facilitate heat dissipation. SMT spacers come in two main varieties: threaded and unthreaded.

- Threaded SMT spacers feature internal or external threads, allowing screws or bolts to secure the PCB firmly.

- Unthreaded SMT spacers are smooth cylindrical components without threads, often designed for easy placement and soldering directly onto the PCB.

While threaded spacers provide strong mechanical fastening, unthreaded SMT spacers offer unique benefits that make them highly suitable for many PCB designs.

Advantages of Unthreaded SMT Spacers for PCB

1. Simplified Assembly and Handling

Unthreaded SMT spacers are designed for installation using standard SMT assembly processes, often packaged on tape and reel for automated pick-and-place machines. This integration minimizes manual handling and reduces the risk of damage during assembly. Unlike threaded spacers, which require additional fastening hardware and manual screwing, unthreaded spacers can be soldered directly onto the PCB, streamlining production and saving time.

The elimination of screws and nuts reduces the complexity of the assembly process. This is especially beneficial in high-volume manufacturing environments where speed and repeatability are critical. The ability to place unthreaded SMT spacers alongside other SMT components on the same assembly line improves workflow efficiency and reduces the chance of assembly errors.

2. Enhanced Process Reliability

Threaded SMT spacers can suffer from tin inflow into the threads during reflow soldering, causing difficulties in screwing and reduced solder paste retention. Unthreaded spacers avoid this issue entirely, as their smooth surfaces prevent capillary action that draws solder into threads. This results in more consistent solder joints, better spacer retention, and fewer assembly defects.

Moreover, unthreaded SMT spacers provide a more reliable mechanical connection to the PCB because the solder fillet forms uniformly around the spacer base. This uniform soldering ensures better vibration resistance and mechanical stability, which is essential in applications exposed to shocks or mechanical stress, such as automotive or industrial electronics.

3. Cost Efficiency

Because unthreaded SMT spacers eliminate the need for screws, nuts, or additional fastening components, they reduce the overall parts count and procurement complexity. Their compatibility with automated SMT lines also lowers labor costs and assembly time. These factors contribute to a more cost-effective PCB manufacturing process.

Additionally, unthreaded SMT spacers typically have a simpler manufacturing process compared to threaded spacers, which require precision threading operations. This simplicity often translates into lower component costs, especially when ordering in large volumes.

4. Flexibility in Design and Material Choice

Unthreaded SMT spacers are available in a wide range of materials such as brass, stainless steel, nylon (polyamide), POM, PVC, and polystyrene. Each material offers distinct benefits:

- Nylon and PA spacers provide excellent electrical insulation, chemical resistance, and lightweight properties.

- POM spacers offer high mechanical strength, dimensional stability, and wear resistance.

- PVC and PS spacers are cost-effective and provide good insulation and chemical resistance.

- Metal spacers like brass and stainless steel add mechanical robustness and conductivity when needed.

This variety allows designers to select unthreaded SMT spacers tailored to specific mechanical, thermal, and electrical requirements. For example, nylon spacers are ideal for applications requiring electrical insulation and resistance to moisture, while metal spacers are preferred when grounding or heat dissipation is necessary.

5. Reduced Risk of PCB Damage

Unthreaded spacers typically require no through-hole threading or tapping, which preserves PCB integrity and reduces potential stress points. Their smooth design also facilitates easier removal or replacement during maintenance or rework, minimizing the risk of damage to the PCB or components.

Threaded spacers often require precise hole sizes and can induce stress concentrations around the mounting points, increasing the risk of PCB cracking or delamination, especially in multilayer or thin boards. Unthreaded SMT spacers, by contrast, rely on soldering and surface mounting, which distribute mechanical forces more evenly.

Common Applications of Unthreaded SMT Spacers

Unthreaded SMT spacers are widely used in:

- Consumer electronics where lightweight and insulation are priorities.

- Automotive and industrial machinery requiring chemical resistance and durability.

- High-density PCB assemblies where precise spacing and minimal footprint are critical.

- Automated SMT production lines demanding fast, reliable, and repeatable assembly processes.

- Medical devices where cleanliness and reliability are paramount, and threaded fasteners might introduce contamination risks.

Their versatility and compatibility with automated assembly make unthreaded SMT spacers a preferred choice across diverse industries.

Material Comparison for Unthreaded SMT Spacers

| Material | Key Benefits | Typical Use Cases |

| Nylon (PA) | Excellent insulation, chemical resistance, lightweight | Electronics, automotive |

| POM | High mechanical strength, dimensional stability | Load-bearing applications |

| PVC | Strong, corrosion-resistant, good insulation | Harsh environments |

| Polystyrene (PS) | Cost-effective, good insulation | Budget-sensitive projects |

| Brass/Stainless Steel | Mechanical strength, conductivity, corrosion resistance | Mechanical support, grounding |

Each material's properties influence the spacer's performance in terms of mechanical durability, electrical insulation, thermal stability, and chemical resistance. Selecting the right material is essential for ensuring long-term reliability of the PCB assembly.

Design Considerations When Using Unthreaded SMT Spacers

When integrating unthreaded SMT spacers into PCB designs, several factors should be considered:

- Spacer height: Must be chosen to provide adequate clearance for components, connectors, and heat sinks.

- Pad size and layout: Pads on the PCB should be designed to accommodate the spacer base for optimal solder joint formation.

- Thermal expansion: Material selection should consider the coefficient of thermal expansion (CTE) to minimize stress during temperature cycling.

- Load requirements: The mechanical load the spacer must support will influence both material and size selection.

- Environmental conditions: Exposure to moisture, chemicals, or extreme temperatures requires appropriate material choice.

Proper design ensures that unthreaded SMT spacers perform their function without compromising PCB integrity or assembly quality.

Comparison Between Threaded and Unthreaded SMT Spacers

| Feature | Threaded SMT Spacers | Unthreaded SMT Spacers |

| Assembly Process | Manual or semi-automated, requires screws | Fully compatible with automated SMT assembly |

| Mechanical Fastening | Strong, screw-based | Soldered, relies on solder joint strength |

| Risk of PCB Damage | Higher due to threading/tapping | Lower, no threading required |

| Cost | Higher due to additional hardware | Lower, fewer components needed |

| Process Reliability | Tin inflow into threads can cause issues | No tin inflow, more reliable solder joints |

| Material Variety | Limited by threading capabilities | Wide variety of materials available |

| Repair and Rework | More complex due to screws | Easier to remove and replace |

This comparison highlights why unthreaded SMT spacers are increasingly favored in modern PCB manufacturing, especially where automation, cost, and reliability are priorities.

Conclusion

Choosing unthreaded SMT spacers over threaded options for your PCB offers numerous benefits, including simplified assembly, enhanced process reliability, cost savings, and design flexibility. Their compatibility with automated SMT processes and wide material selection make them an excellent choice for modern PCB manufacturing, particularly where electrical insulation and mechanical support are essential without the complexity of threaded fasteners.

By understanding the specific advantages and applications of unthreaded SMT spacers, designers and manufacturers can optimize their PCB assemblies for performance, reliability, and cost-efficiency. Whether you are working on consumer electronics, automotive systems, or industrial machinery, unthreaded SMT spacers provide a practical and efficient solution for your PCB spacing needs.

FAQ

1. What are unthreaded SMT spacers used for in PCB assembly?

Unthreaded SMT spacers are used to provide precise spacing, mechanical support, and electrical insulation between the PCB and other components or assemblies. They are soldered directly onto the PCB in automated SMT processes.

2. How do unthreaded SMT spacers improve assembly efficiency?

They are compatible with automated pick-and-place machines and do not require additional fastening hardware, reducing manual labor and assembly time.

3. What materials are commonly used for unthreaded SMT spacers?

Common materials include nylon (PA), POM, PVC, polystyrene, brass, and stainless steel, each offering different mechanical and electrical properties to suit various applications.

4. Are unthreaded SMT spacers suitable for high-temperature environments?

Certain materials like ceramic and some metals can withstand high temperatures, while plastics like nylon and POM have moderate temperature resistance. Material choice should match the operating environment.

5. Can unthreaded SMT spacers be used in load-bearing applications?

Yes, especially those made from POM or metal, which provide high mechanical strength and durability suitable for supporting heavier components or assemblies.