Content Menu

● Understanding SMT Manufacturing and Supply

>> Key Features of SMT

● Advantages of SMT in Electronics Assembly

>> Higher Component Density

>> Improved Electrical Performance

>> Faster Production Times

>> Cost Reduction

>> Flexibility and Design Innovation

● Applications of SMT

● The Future of SMT in Electronics Manufacturing

● Conclusion

● Related Questions

>> 1. What are the main differences between SMT and through-hole technology?

>> 2. How does SMT improve manufacturing efficiency?

>> 3. What types of products commonly use SMT?

>> 4. Are there any downsides to using SMT?

>> 5. How does automation impact SMT assembly?

In the rapidly evolving world of electronics, the choice of assembly technology can significantly impact product performance, cost, and time to market. Surface Mount Technology (SMT) has emerged as a leading method for electronic assembly, offering numerous advantages over traditional through-hole techniques. This article explores the reasons why manufacturers should consider SMT for their electronics assembly needs, delving into its benefits, applications, and implications for the future of electronic manufacturing.

Understanding SMT Manufacturing and Supply

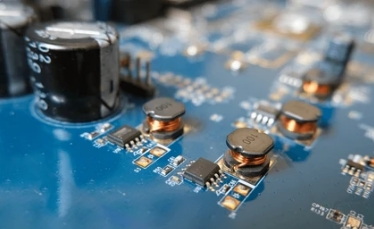

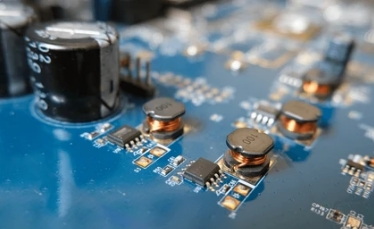

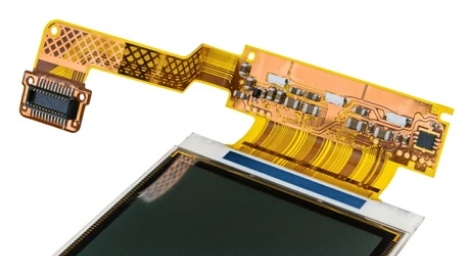

Surface Mount Technology involves mounting electronic components directly onto the surface of printed circuit boards (PCBs). Unlike through-hole technology, where components are inserted into holes drilled in the PCB, SMT allows for a more compact design. This method has gained popularity due to its ability to support high-density assemblies and facilitate automation in manufacturing processes.

Key Features of SMT

- Compact Design: SMT components are significantly smaller than their through-hole counterparts, which allows for more components to be placed on a single board. This compactness is crucial in today's electronics, where miniaturization is often a requirement.

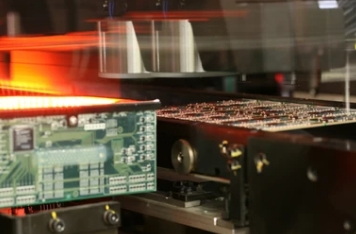

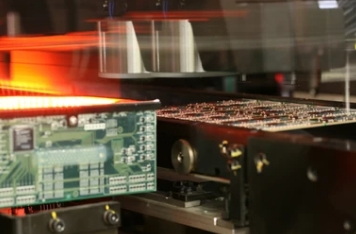

- Automated Assembly: The SMT process can be largely automated, reducing labor costs and increasing production speed. Automated machines can place components with high precision, ensuring consistency and reliability in manufacturing.

- Cost Efficiency: By eliminating the need for drilling holes and reducing material handling, SMT can lower production costs. The smaller size of components also contributes to reduced shipping and packaging costs.

Advantages of SMT in Electronics Assembly

Higher Component Density

One of the most significant advantages of SMT is its ability to accommodate a higher density of components on a PCB. This is achieved by placing components on both sides of the board and utilizing smaller parts that do not require leads to pass through holes. The result is a more efficient use of space, which is essential for modern electronic devices that demand compact designs.

Improved Electrical Performance

SMT enhances electrical performance due to shorter signal paths between components. This reduction in lead length minimizes inductance and resistance, leading to faster signal transmission and improved overall functionality. Devices assembled using SMT are often more responsive and reliable, making them suitable for high-performance applications.

Faster Production Times

The automated nature of SMT assembly allows for quicker production cycles compared to traditional methods. The process eliminates many manual steps involved in through-hole assembly, such as drilling and inserting leads. As a result, manufacturers can achieve faster turnaround times for prototypes and mass production runs alike.

Cost Reduction

SMT typically results in lower overall production costs. The elimination of drilling processes reduces labor and material costs while allowing manufacturers to produce more units in less time. Additionally, the smaller size of SMT components often means lower material costs per unit.

Flexibility and Design Innovation

SMT supports innovative design approaches by allowing engineers greater flexibility in component placement and board layout. This flexibility enables the integration of complex functionalities into smaller devices without compromising performance or reliability.

Applications of SMT

SMT is widely used across various industries due to its versatility and efficiency. Some common applications include:

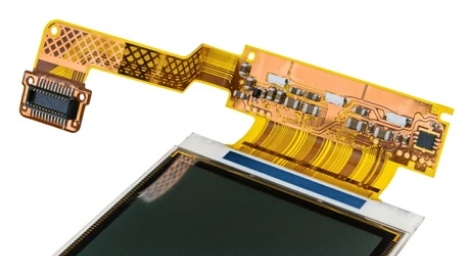

- Consumer Electronics: Smartphones, tablets, and laptops utilize SMT for compact designs that enhance portability without sacrificing functionality.

- Medical Devices: High-density assemblies are crucial in medical equipment where space is limited but performance is critical.

- Telecommunications: Devices such as routers and switches benefit from SMT's ability to support high-frequency signals and complex circuitry.

- Automotive Electronics: Modern vehicles increasingly rely on compact electronic systems that enhance safety features and improve fuel efficiency.

The Future of SMT in Electronics Manufacturing

As technology advances, the demand for smaller, more efficient electronic devices continues to grow. SMT is poised to play a crucial role in meeting these demands due to its inherent advantages in design flexibility, cost efficiency, and production speed. Furthermore, ongoing innovations in automation technologies promise to enhance the capabilities of SMT processes even further.

Conclusion

Choosing Surface Mount Technology for electronics assembly presents numerous advantages that align with the current trends towards miniaturization and efficiency in manufacturing. With benefits ranging from higher component density to improved electrical performance and reduced costs, SMT stands out as a preferred method for modern electronics manufacturing. As industries continue to evolve, embracing SMT will be essential for companies looking to remain competitive in an increasingly demanding market.

Related Questions

1. What are the main differences between SMT and through-hole technology?

SMT involves placing components directly on the surface of PCBs without drilling holes, while through-hole technology requires leads to pass through holes drilled into the PCB. This difference affects component size, assembly speed, and overall board density.

2. How does SMT improve manufacturing efficiency?

SMT improves efficiency by automating many steps in the assembly process, reducing manual labor requirements, speeding up production times, and minimizing material handling through its compact design.

3. What types of products commonly use SMT?

SMT is commonly used in consumer electronics (like smartphones), medical devices (such as diagnostic equipment), telecommunications devices (like routers), and automotive electronics (including safety systems).

4. Are there any downsides to using SMT?

While SMT offers many advantages, potential downsides include challenges with soldering small components accurately and difficulties in reworking or repairing boards compared to through-hole technology.

5. How does automation impact SMT assembly?

Automation enhances SMT assembly by increasing precision in component placement, speeding up production processes, reducing labor costs, and improving overall product quality through consistent manufacturing practices.